Oil tanks with level gauge for turbines

A turbine and box technology, applied in the direction of the engine level, turbine/propulsion device lubrication, measurement devices, etc., can solve complex quality and seal inspection problems, achieve the effects of optimizing accessibility, reducing costs, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

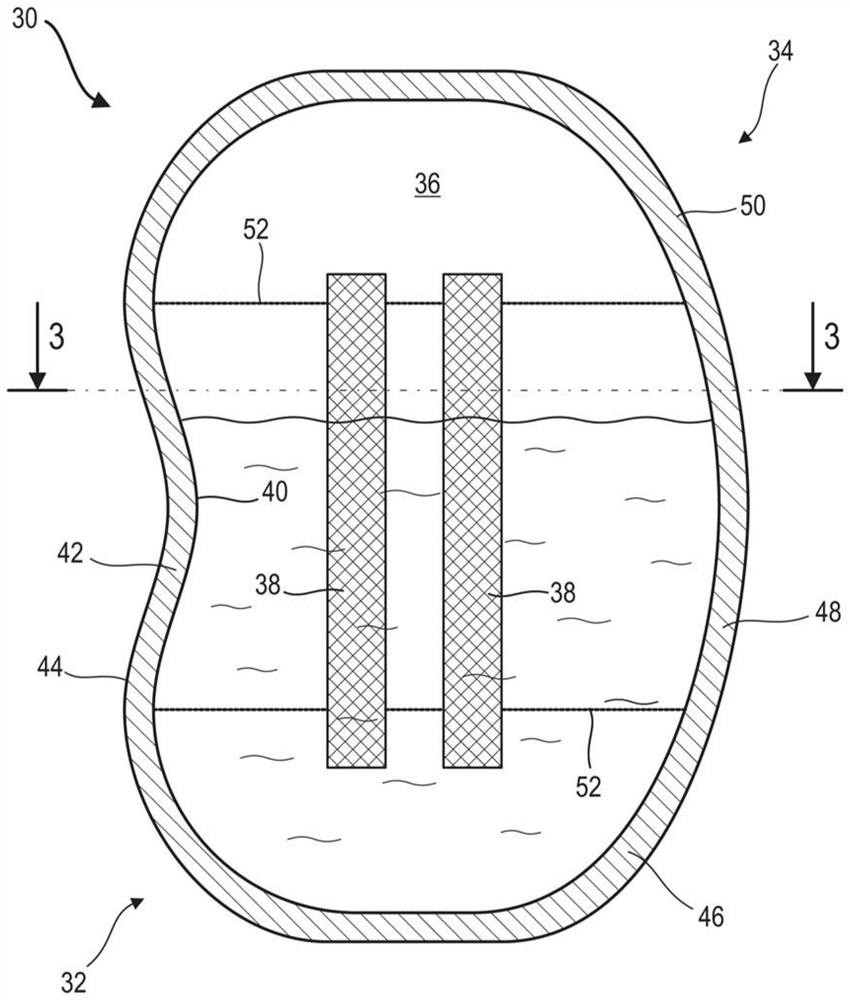

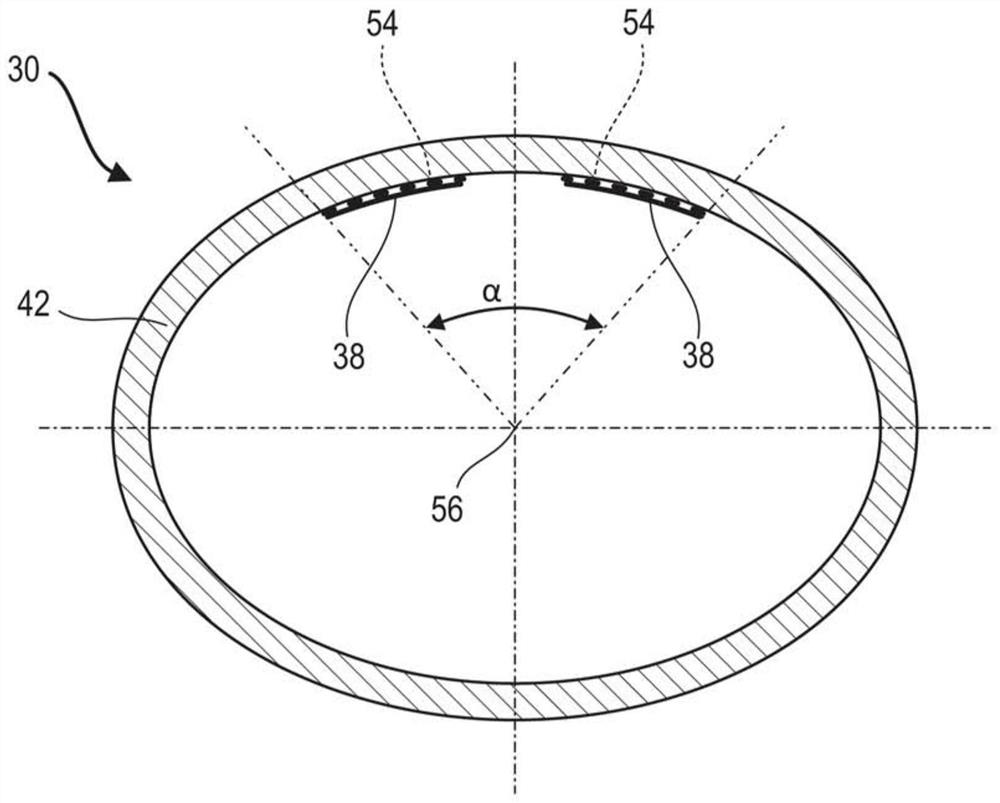

[0056] In the following description, the axial direction corresponds to the direction in which the axis of rotation along the turbine is extended. The radial direction is perpendicular to the axis of rotation. The upstream and downstream refers to the main flow direction of the fluid in the turbine. The height and vertical aspect of the cabinet are related to the normal assembly direction.

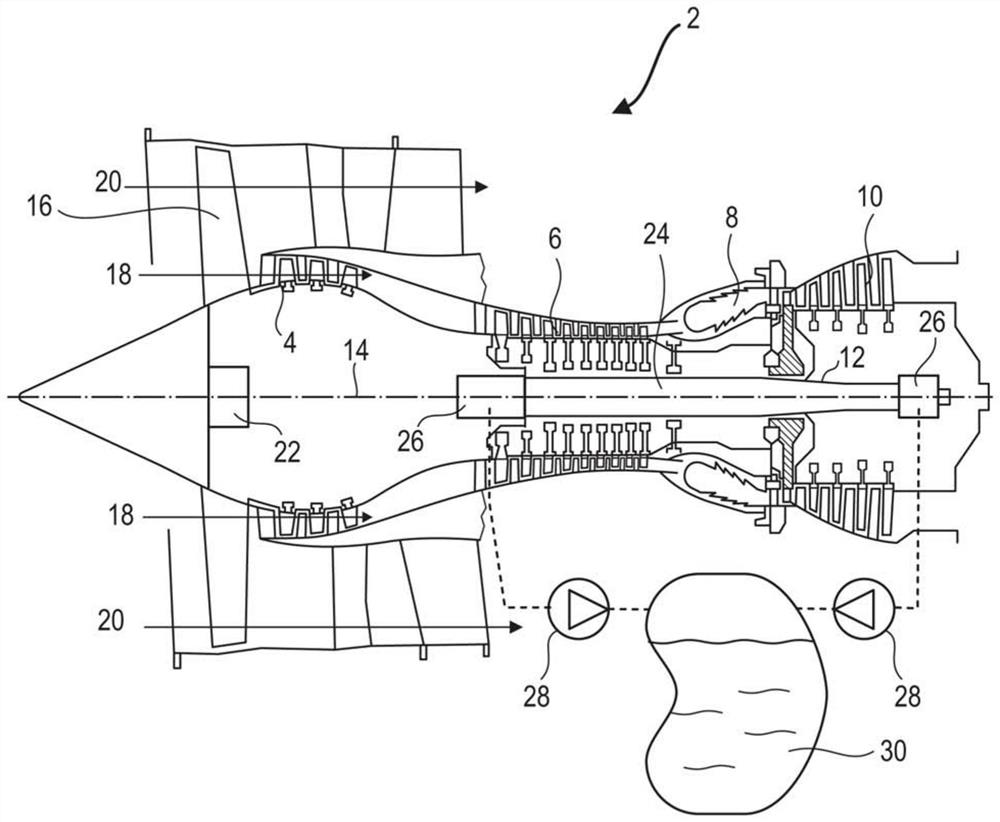

[0057] figure 1 It is a simplified schematic of a shaft turbine. In this specific case, it is a diblant scroll engine. The vortex engine 2 has a first compression stage called the low pressure compressor 4, referred to as a second compression stage, combustion chamber 8, and one or more turbine level 10 of the high pressure compressor 6. In operation, the mechanical power of the turbine 10 of the rotor 12 is transferred via the shaft to move the two compressors 4 and 6. The latter two have a plurality of roller blades associated with the arranged stator blade. Thereby, the rotor rotates about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com