Downhole sand fracturing system of coal mine

A sand fracturing and coal mine technology, applied in mining equipment, wellbore/well parts, gas discharge, etc., can solve problems such as unfavorable gas release, easy closure of cracks, inconvenient post-drainage, etc., to improve work efficiency and reduce The effect of labor intensity and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

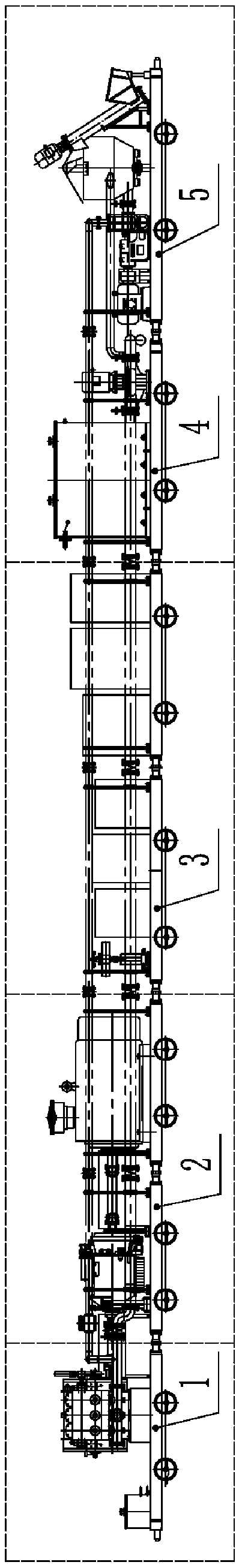

[0017] Attached below figure 1 , 2 The present invention will be described in detail with specific embodiments.

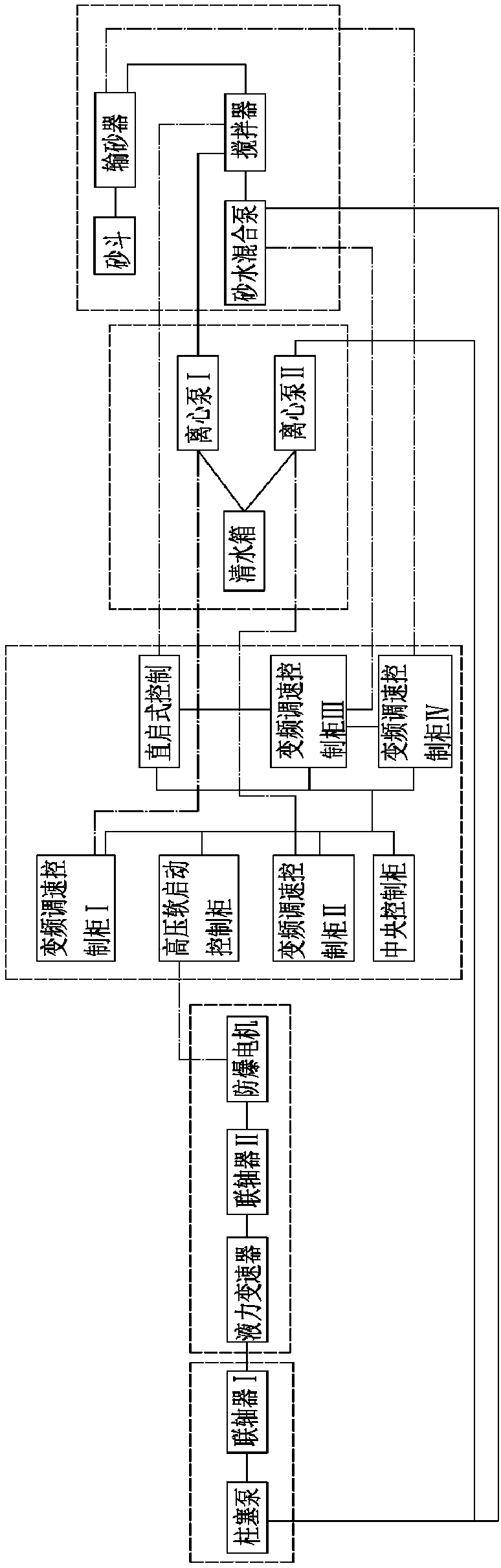

[0018] An underground coal mine sand fracturing system, which is composed of a fracturing pump module, a power module, an electric control module, a clean water pump module, and a sand mixing module; a plunger pump is arranged on the fracturing pump module, and the plunger pump The power input end is connected with the power output end of the hydraulic transmission through coupling I; the power module is arranged with a hydraulic transmission and an explosion-proof motor, and the power input end of the hydraulic transmission and the main shaft of the explosion-proof motor pass through coupling II connection; the clean water pump module is arranged with centrifugal pump I, centrifugal pump II and clean water tank, and the suction ports of centrifugal pump I and centrifugal pump II are respectively connected with the clean water tank through pipelines; sand mixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com