Vertical multi-hinge connection structure between assembled shear walls and construction method

A construction method and shear wall technology, applied in the direction of building structure, construction, etc., can solve the problems of high processing and installation precision, high technical requirements for workers, and difficulty in reaching the standard of strength, and achieve non-destructive, high degree of industrialization, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

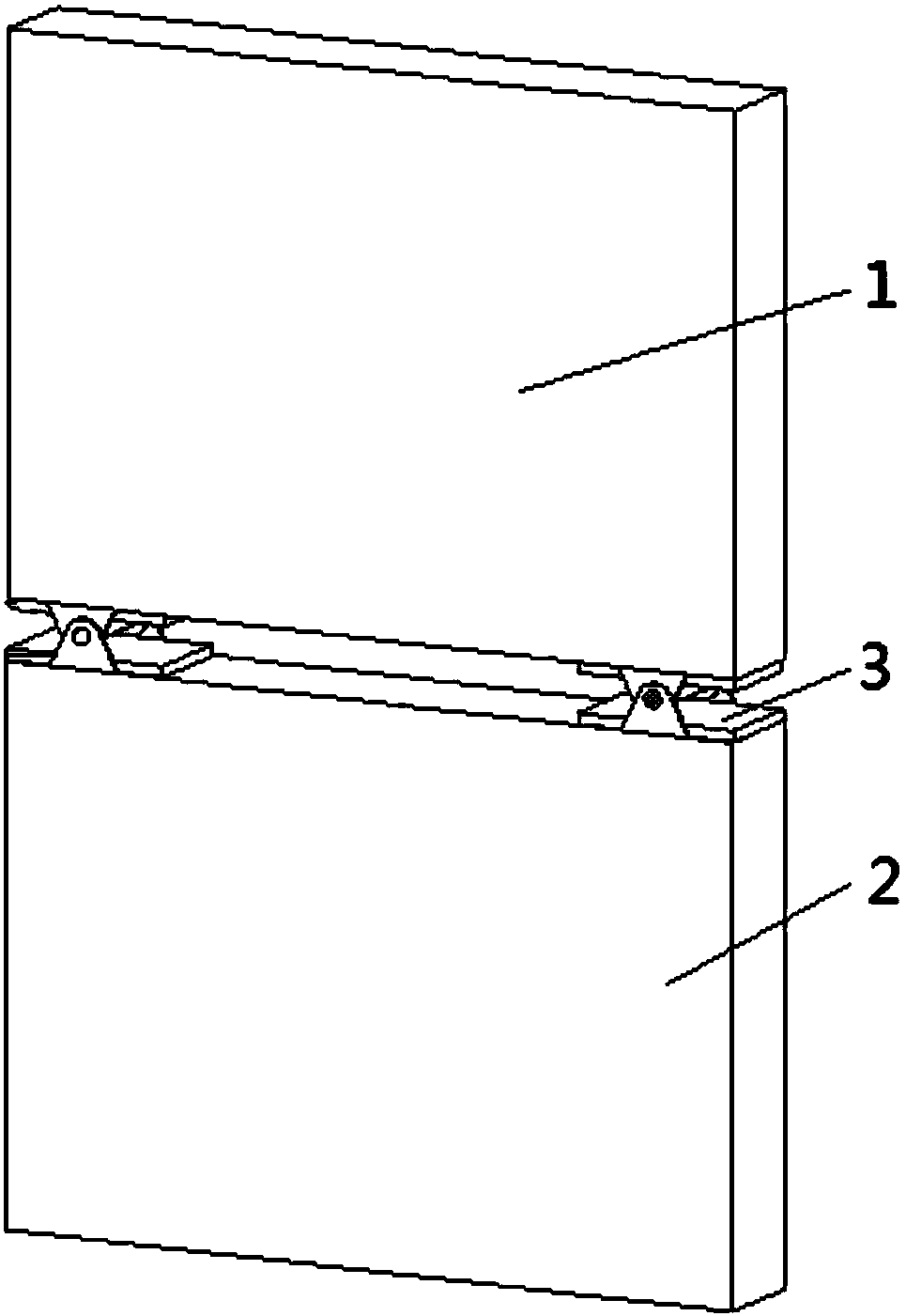

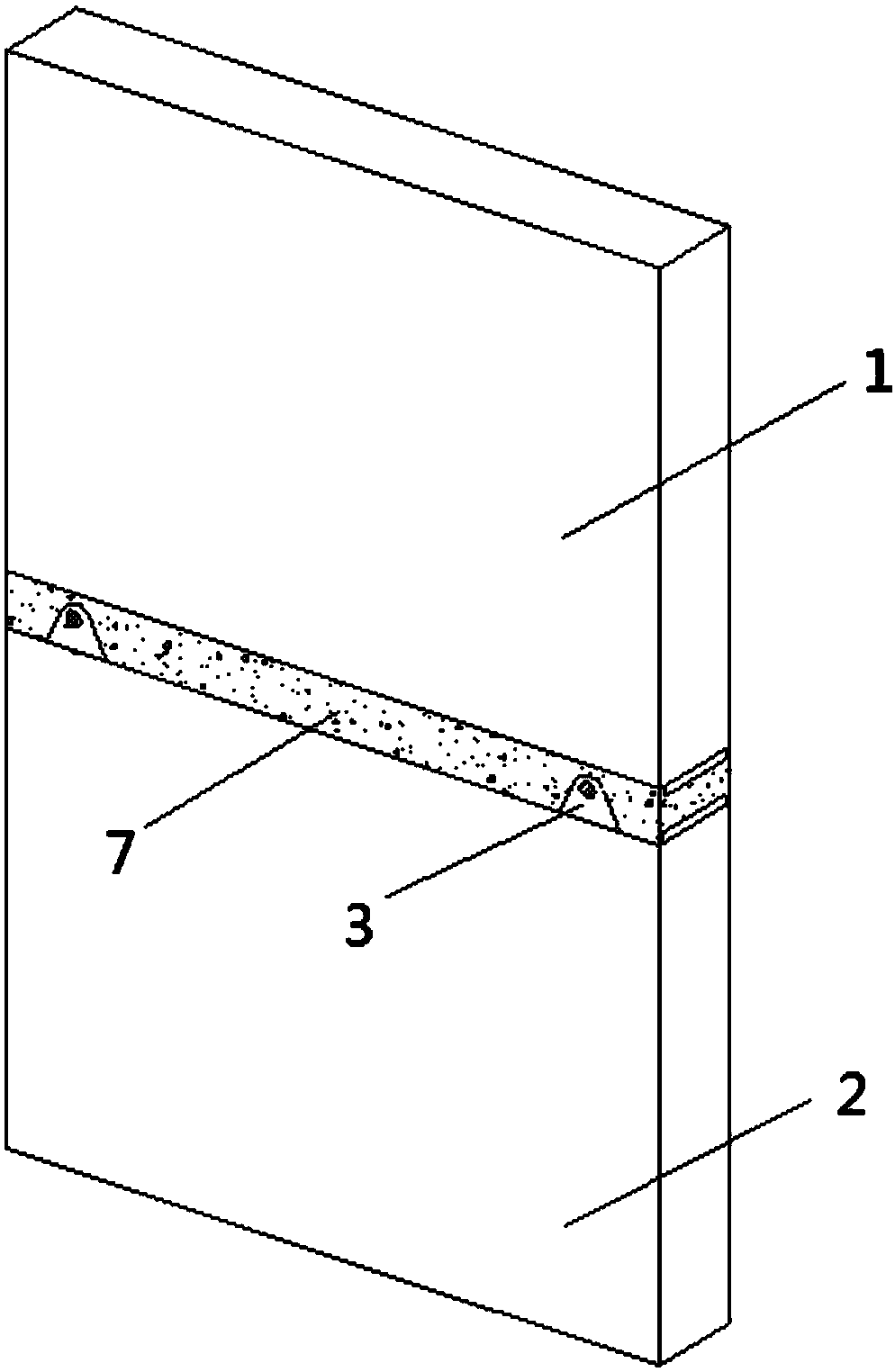

[0032] Example 1, such as Figure 1 to Figure 4 As shown, the vertical multi-hinge connection structure between the prefabricated shear walls of the present invention includes the first prefabricated shear wall 1, the second prefabricated shear wall 2 and the embedded connector 3;

[0033] The first prefabricated shear wall 1 and the second prefabricated shear wall 2 are arranged vertically, and the first prefabricated shear wall 1 is connected to the second prefabricated shear wall 2 through at least two embedded connectors 3;

[0034] The gap between the first prefabricated shear wall 1 and the second prefabricated shear wall 2 is filled with grouting material 7 .

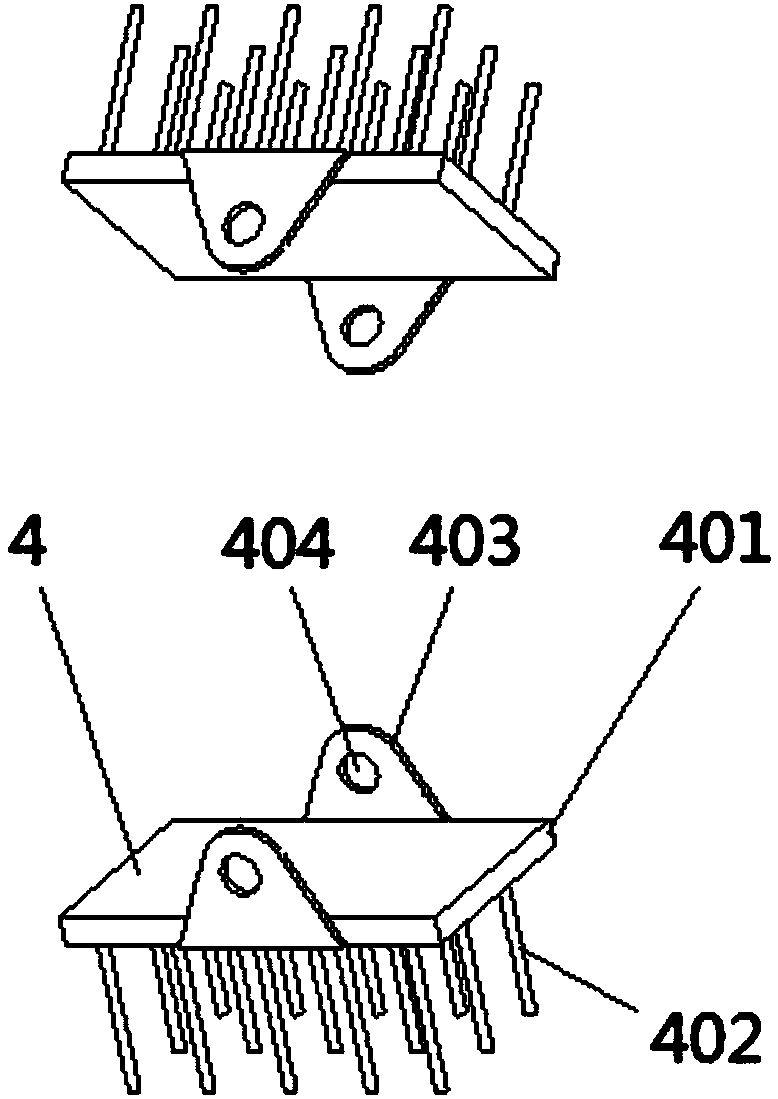

[0035] Further: the pre-embedded connector 3 includes two lug assemblies 4 and bearing rods 5, one of which is pre-embedded on the bottom end surface of the first prefabricated shear wall 1, and the other lug assembly 4 is pre-embedded On the top end surface of the second prefabricated shear wall 2; the two lug ...

Embodiment 2

[0039] Embodiment 2, the construction method of the vertical multi-hinge connection structure between the prefabricated shear walls, comprises the following steps:

[0040] Step 1: Prefabrication of the shear wall; place the prefabricated two ear plate assemblies 4 on the same side of the shear wall formwork 6, and fix them with the steel bars inside the shear wall by spot welding; Concrete is poured in the center to complete the production of the shear wall;

[0041] Step 2: Preliminary connection of the first prefabricated shear wall 1 and the second prefabricated shear wall 2; at the construction site, first hoist the second prefabricated shear wall 2 in place, and then hoist the first prefabricated shear wall 1 to The top of the second prefabricated shear wall 2, and make the bearing hole 404 position on the upper and lower lug assembly 4 correspond, then insert the bearing rod 5 in the bearing hole 404, complete the first prefabricated shear wall 1 and the second Prefabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com