Construction method of sewage pipeline and bases

A technology of sewage pipelines and construction methods, which is applied in the direction of sewer pipeline systems, waterway systems, water supply devices, etc., and can solve the problems of pipe offset, pipe end conflicting with the side wall of the trench, low integrity and stability, etc., to achieve Guarantee the effect of working cycle, fast and smooth pipeline connection, and straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

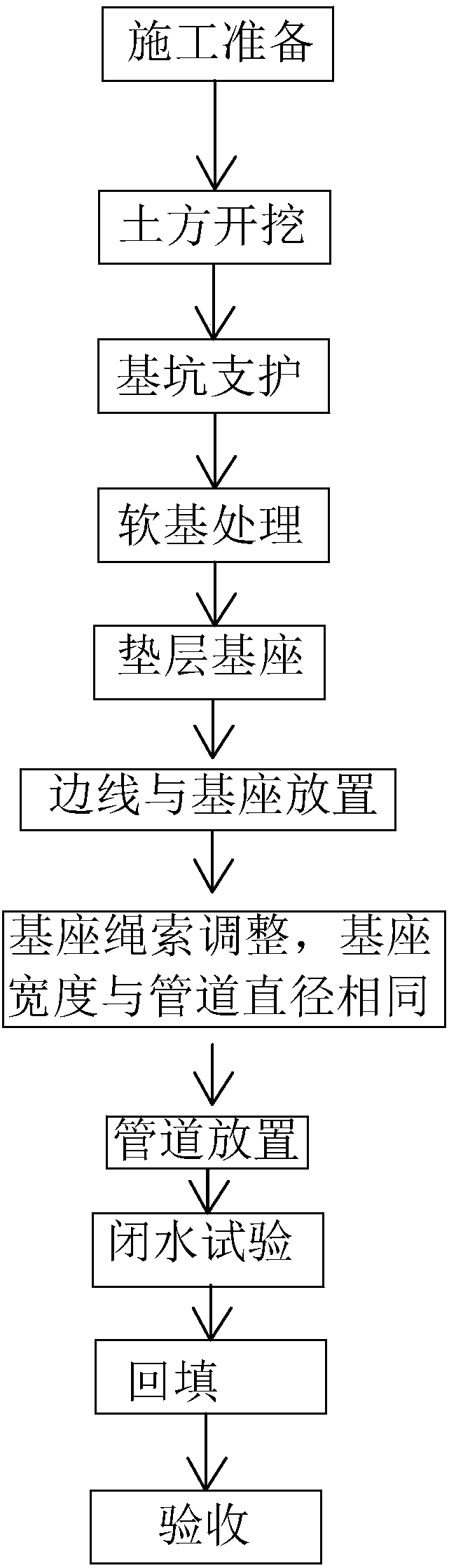

[0049] Embodiment 1, the construction method of sewage pipeline, as figure 1 as shown,

[0050] Pre-construction preparations, inspection of each construction equipment and site to check whether the construction equipment is in good condition and whether the construction site is safe.

[0051] Earthwork development: Excavating foundation pits and inspection wells.

[0052] Foundation pit excavation and other earthworks are mainly constructed by excavators.

[0053] The downpipe line section can only be excavated manually, and after the excavation is 20-30cm away from the design elevation, it will be leveled manually to avoid over-excavation and disturbance of the soil foundation. The soil to be transferred shall be transported by dump truck.

[0054] Excavation of the foundation pit shall be carried out in layers and sections in sequence. When excavating layer by layer and below the groundwater level, set up drainage ditches and water collection wells. , Its length × wid...

Embodiment 2

[0084] Embodiment 2, it differs from Embodiment 1 in that, as figure 2 As shown, in step , that is, in the step of "sideline and base setting", further operations are performed on the base:

[0085] First: adjust the distance between the two opposite bases to be the same as the diameter of the pipe, and then the base is fixed in the foundation pit by concrete.

[0086] Again: support ropes are set between two relative bases, and the ropes are hemp ropes. Pull one end of the rope to adjust the length of the rope between the bases; if the height of the pipe is lower than the sideline, tighten the rope so that the rope raises the pipe, and fix the rope after the height of the upper end of the pipe is equal to the sideline;

[0087] If the pipeline is higher than the sideline, loosen the rope. After the rope is loose, the height of the pipeline is lowered. After the height of the upper end of the pipeline is equal to the sideline, the rope is fixed. The rope is fixed to the bas...

Embodiment 3

[0090] Embodiment 3, for the base in the method of embodiment 1 or embodiment 2. Such as image 3 and Figure 4 As shown, a pedestal includes a pedestal body 1, and two pedestals are arranged facing each other to form a group. The facing surfaces of the two pedestal bodies 1 are vertical surfaces, and the pedestal body 1 is divided into an upper part and a lower part. The cross-section of the lower part of the pedestal body 1 It is in the shape of a right-angled trapezoid, and the cross section of the upper part of the base is rectangular.

[0091] The upper end of the seat body 1 is provided with a hanging hole 2, and the hanging hole 2 is used for hooking the hook of the lifting equipment to fix it.

[0092] The lower part of the seat body 1 is provided with a perforation 3 , and two opposite seat bodies 1 are provided with a rope 4 , the rope 4 is shot through the two through holes 3 , and the rope 4 can move on the perforation 3 . The two ends of the rope 4 are wrapped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com