Pipe gush blocking equipment for dam

A dam and equipment technology, applied in the field of dam plugging and piping equipment, can solve problems such as public life, property loss, dam breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

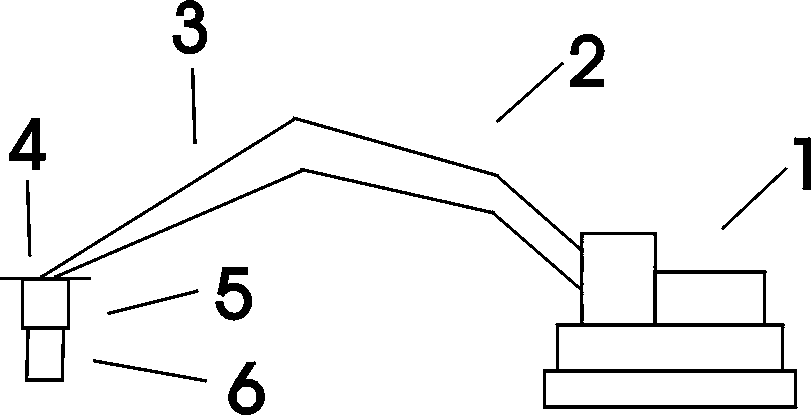

[0053] Embodiment 1, one of embankment blocking pipe gushing equipment, see attached figure 1 . First, install a generator and an air compressor on the excavator 1 . Or set up a combined air compressor in which a generator and an air compressor are combined. Alternatively, the supporting excavator is provided with a combined air compressor that is combined with a generator and an air compressor towed by a trailer.

[0054] Secondly, the pneumatic pick of prior art is transformed. The pneumatic pick is composed of a gas distribution mechanism, an impact mechanism and a pick brazing. The impact mechanism is a thick-walled cylinder with an impact hammer that can reciprocate along the inner wall of the cylinder. The tail of the pickaxe is inserted into the front end of the cylinder, and the rear end of the cylinder is equipped with a gas distribution valve box.

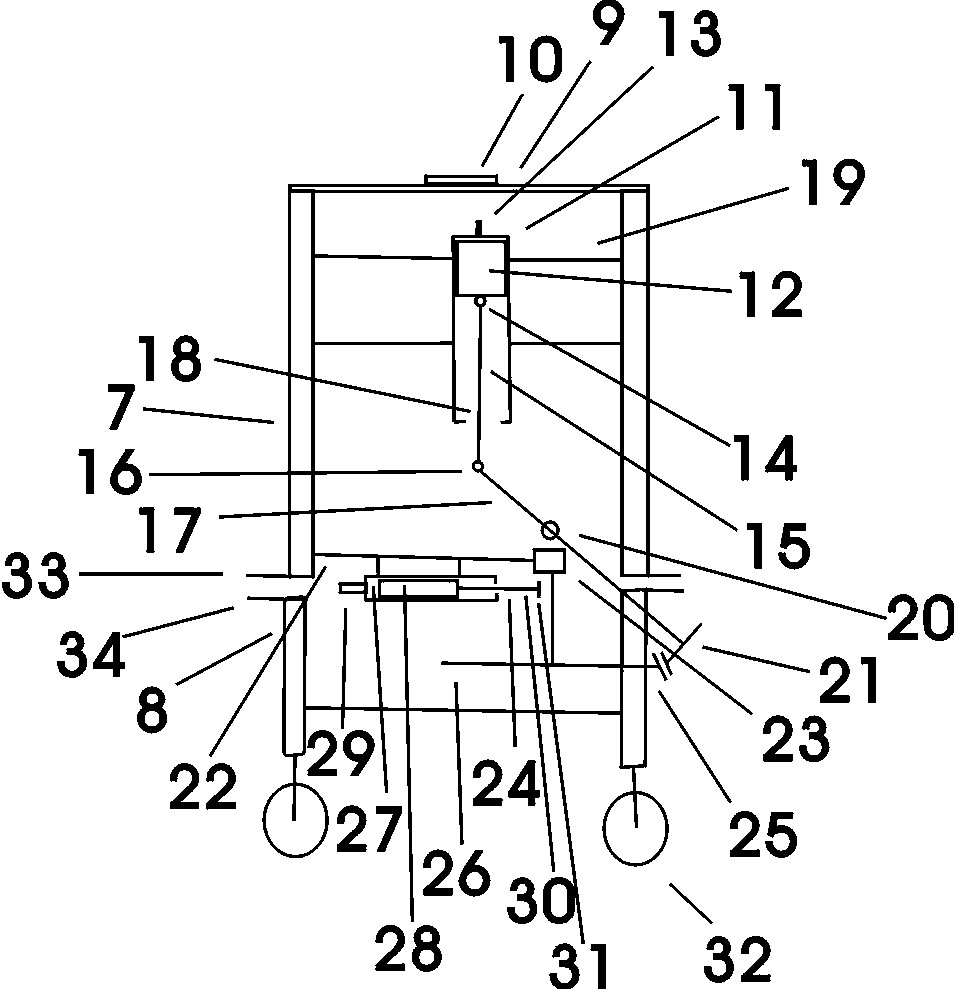

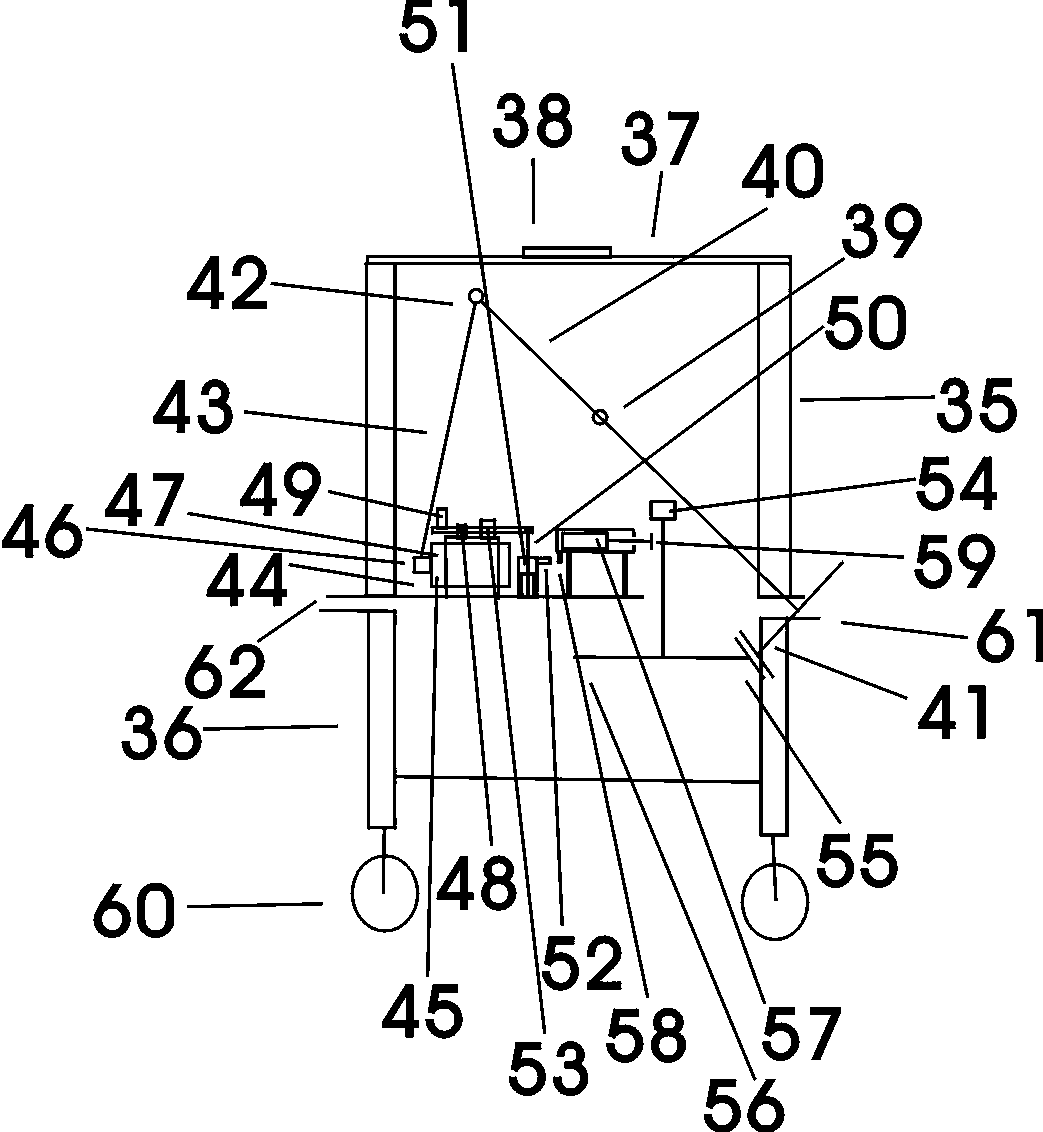

[0055] To transform the air pick is to increase the size of each part of the air pick in proportion. The size of ...

Embodiment 2

[0075] Embodiment two, one of embankment blocking pipe gushing equipment, see attached figure 1 . First, install a generator and an air compressor on the excavator 1 . Or set up a combined air compressor in which a generator and an air compressor are combined. Alternatively, the supporting excavator is provided with a combined air compressor that is combined with a generator and an air compressor towed by a trailer.

[0076] Secondly, the pneumatic pick of prior art is transformed. The pneumatic pick is composed of a gas distribution mechanism, an impact mechanism and a pick brazing. The impact mechanism is a thick-walled cylinder with an impact hammer that can reciprocate along the inner wall of the cylinder. The tail of the pickaxe is inserted into the front end of the cylinder, and the rear end of the cylinder is equipped with a gas distribution valve box.

[0077] To transform the air pick is to increase the size of each part of the air pick in proportion. The size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com