A kind of cross-linkable spray quick-setting rubber asphalt waterproof coating

A technology for waterproof coatings and dispersions, applied in the field of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

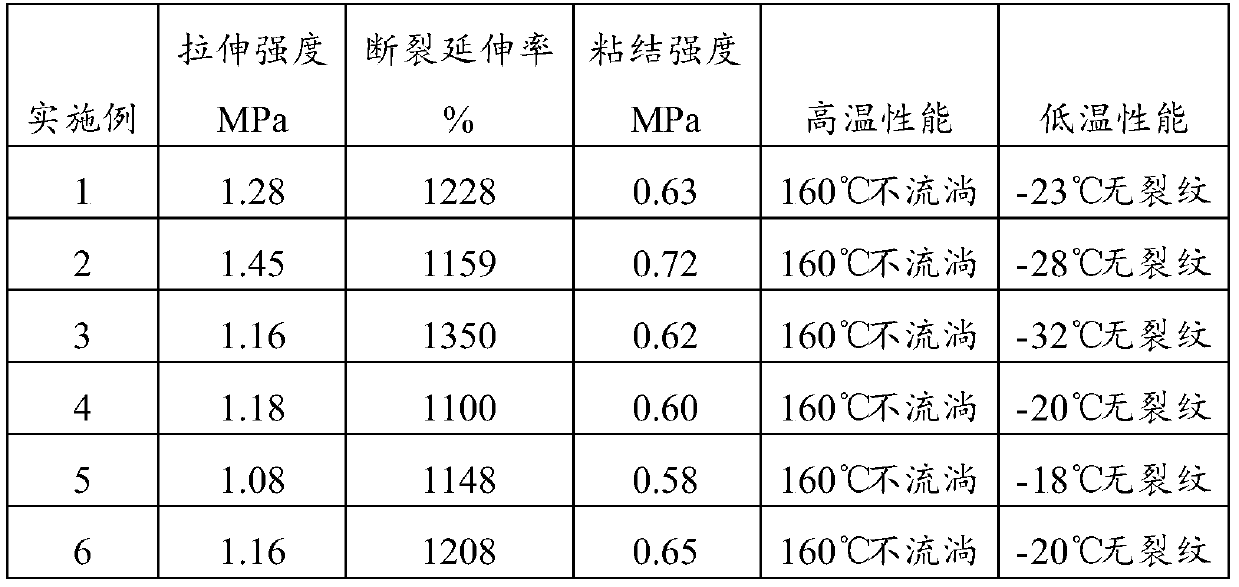

Examples

Embodiment 1

[0053] The cross-linkable spray quick-setting rubber asphalt waterproof coating is divided into ABC components, and the weight percentage of each component of A component is 50% of anionic emulsified asphalt, 30% of neoprene latex, 10% of carbon black dispersion, silica colloid Solution 6.5%, nano-zinc oxide dispersion 3%, catalyst 0.5%; B component is polyisocyanate; C component is calcium chloride with 6% mass concentration. The spray film is sprayed with a special dual-channel double-nozzle spray gun. Before construction, the AB component is stirred evenly and then sprayed with the C component through a dual-channel double-nozzle spray gun. The mass ratio of A to B is 20:1, and the volume ratio of AB (after uniform stirring) to C is 10:1.

Embodiment 2

[0055] The cross-linkable spray quick-setting rubber asphalt waterproof coating is divided into ABC components, and the weight percentage of each component of A component is 50% of anionic emulsified asphalt, 30% of neoprene latex, 10% of carbon black dispersion, silica colloid Solution 6.5%, nano-zinc oxide dispersion 3%, catalyst 0.5%; B component is polyisocyanate; C component is calcium chloride with 6% mass concentration. The spray film is sprayed with a special dual-channel double-nozzle spray gun. Before construction, the AB component is stirred evenly and then sprayed with the C component through a dual-channel double-nozzle spray gun. The mass ratio of A to B is 10:1, and the volume ratio of AB (after uniform stirring) to C is 10:1.

Embodiment 3

[0057] The cross-linkable spray quick-setting rubber asphalt waterproof coating is divided into ABC components, and the weight percentage of each component of A component is 50% of anionic emulsified asphalt, 20% of neoprene latex, 10% of styrene-butadiene latex, and 10% of carbon black dispersion %, 6.5% of silicon dioxide colloidal solution, 3% of nanometer zinc oxide dispersion liquid, and 0.5% of catalyst; B component is polyisocyanate; C component is calcium chloride with 6% mass concentration. The spray film is sprayed with a special dual-channel double-nozzle spray gun. Before construction, the AB component is stirred evenly and then sprayed with the C component through a dual-channel double-nozzle spray gun. The mass ratio of A to B is 10:1, and the volume ratio of AB (after uniform stirring) to C is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com