Industrial robot with visual system and control method of industrial robot

A technology of industrial robots and vision systems, applied in the field of industrial robots and their control, can solve problems such as the inability to meet the requirements of flexible production systems for conveying and handling, and the poor flexibility of production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

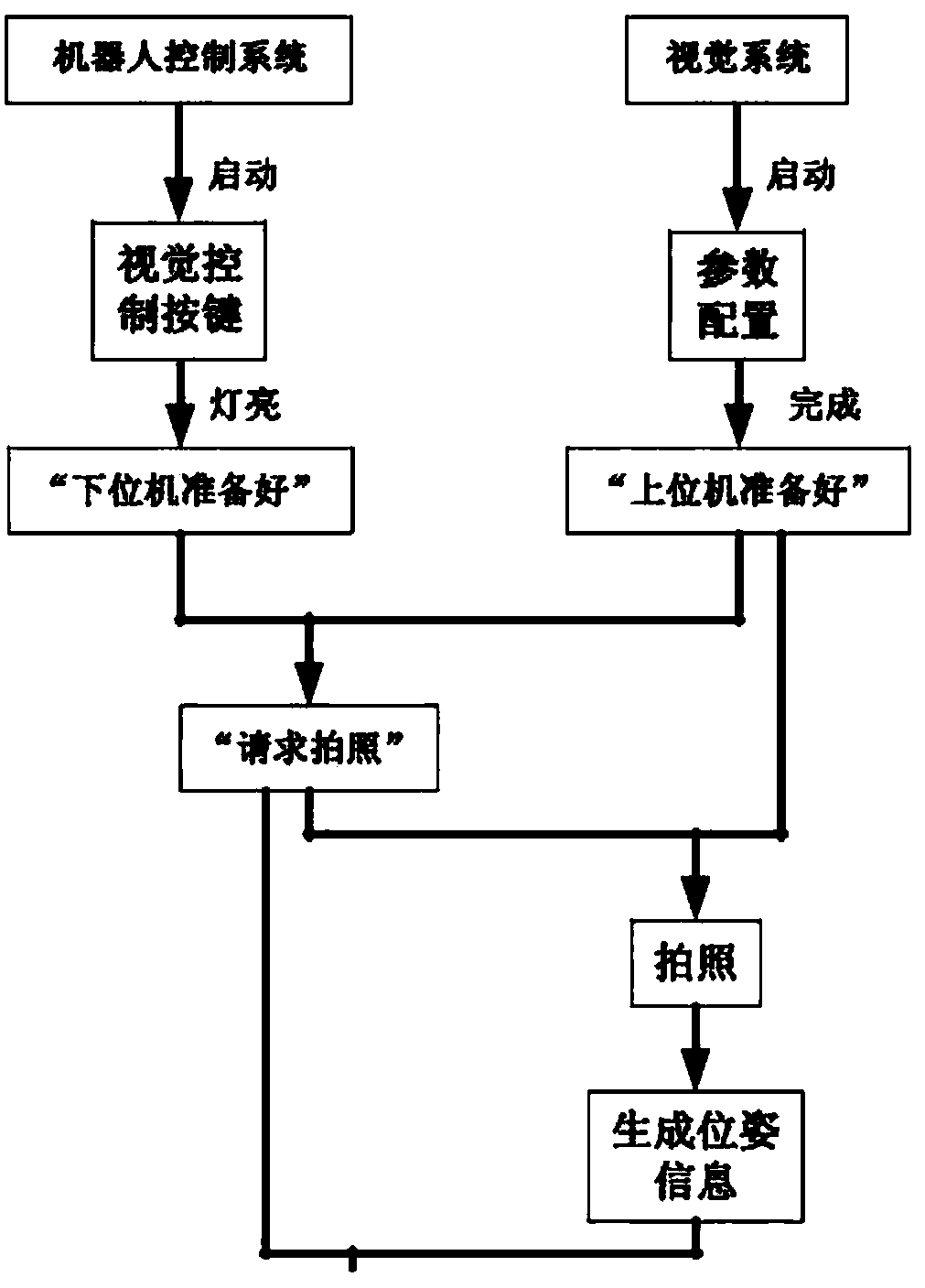

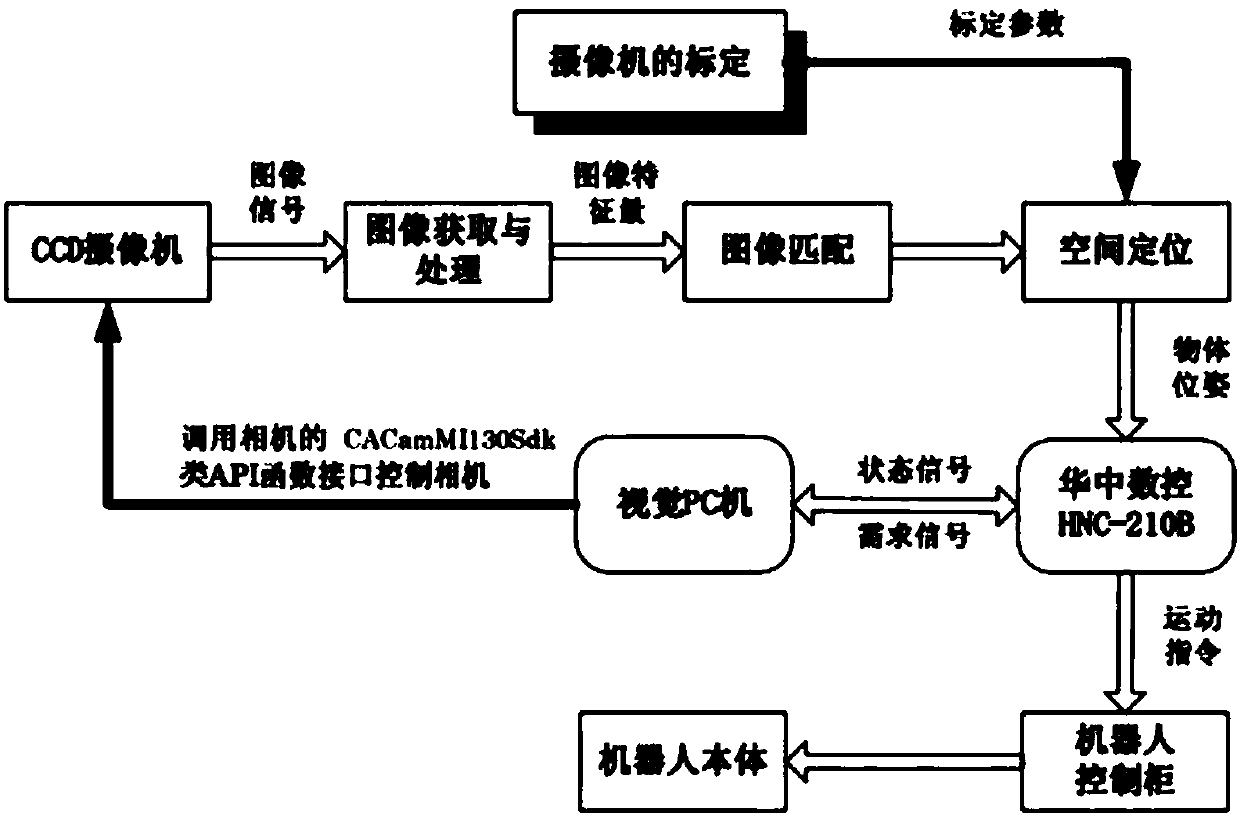

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in the figure, an industrial robot with a vision system includes a robot body, a robot vision system, a robot industrial computer and a control cabinet; five servo drivers, transformers, relays and I / O terminal boards of the robot are installed in the control cabinet , the servo drive adopts the full-digital AC servo drive unit of the model HSV-16 developed by Huazhong CNC. The interfaces XS30, XS31, XS34, XS35 and XS36 of the feed drive device are connected to the industrial computer, and the switches outside the system, such as travel switches and limit switches on each joint of the robot, are connected to the I / O terminals in the electric cabinet. On the board, through one-to-one correspondence, the lead wires from the terminal board are connected to the industrial control system through the XS10 digital input interface;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com