Rubber piece spraying and drying production line

A production line and film technology, applied in spray booths, spray devices, etc., can solve the problems of long parking time, large environmental impact, and high labor intensity of vulcanizers, reducing workload, reducing labor intensity, and shortening spraying and drying. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

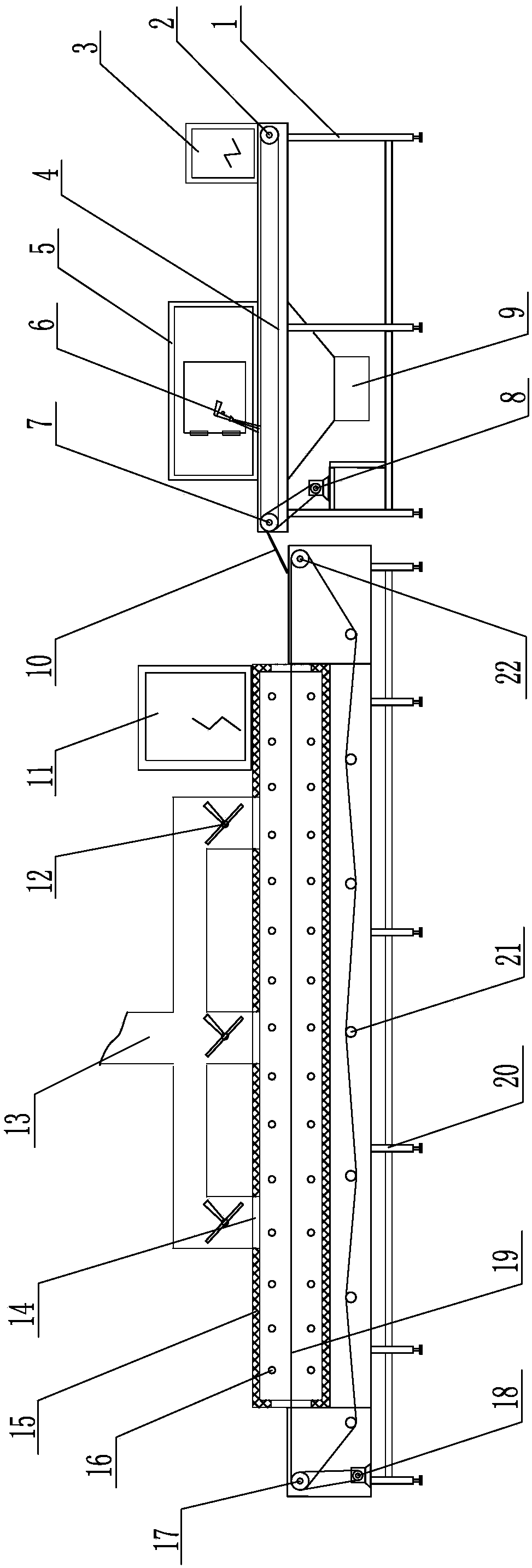

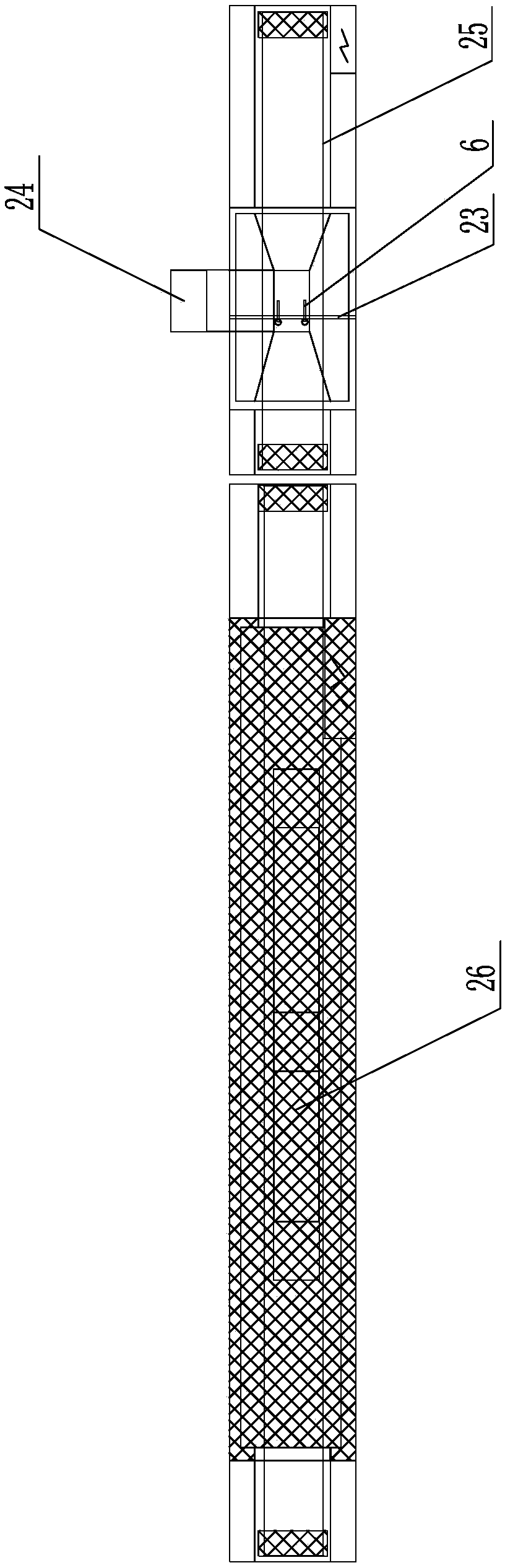

[0022] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0023] Such as Figure 1-Figure 2 As shown, the film spraying and drying production line of the present invention includes a spraying mechanism 25 and a drying mechanism 26. The spraying mechanism 25 and the drying mechanism 26 are connected through a connecting slide 10, and one end of the connecting slide 10 is fixed on the side of the spraying mechanism 25. The end of spraying conveyor belt 4 is connected with the other end of slide plate 10 and the front end of drying conveyor belt 19 of drying mechanism 26 is matched and connected.

[0024] Described spraying mechanism 25 comprises spraying frame 1, and the two ends of spraying frame 1 are respectively provided with spraying main transmission shaft 7 and spraying from transmission shaft 2, and spraying main transmission shaft 7 connects spraying transmission mechanism 8, and spraying main transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com