Seedling raising greenhouse for automatically adjusting temperature and humidity

A technology for humidity regulation and temperature regulation, applied in the field of nursery greenhouses, can solve the problems of incomplete monitoring, errors and delays in temperature and humidity regulation, and achieve the effects of improving monitoring accuracy, avoiding regulation errors and delays, and improving regulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

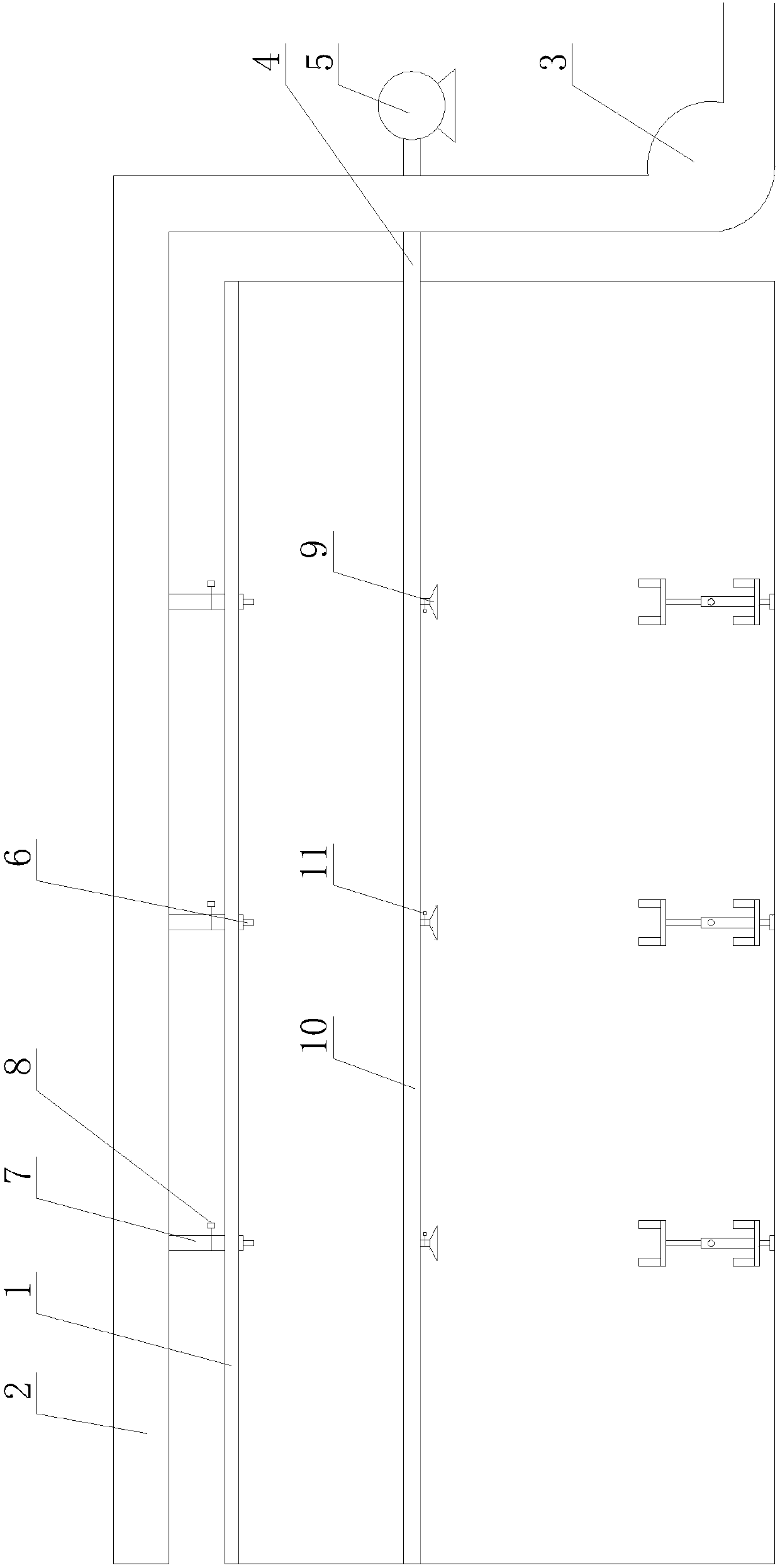

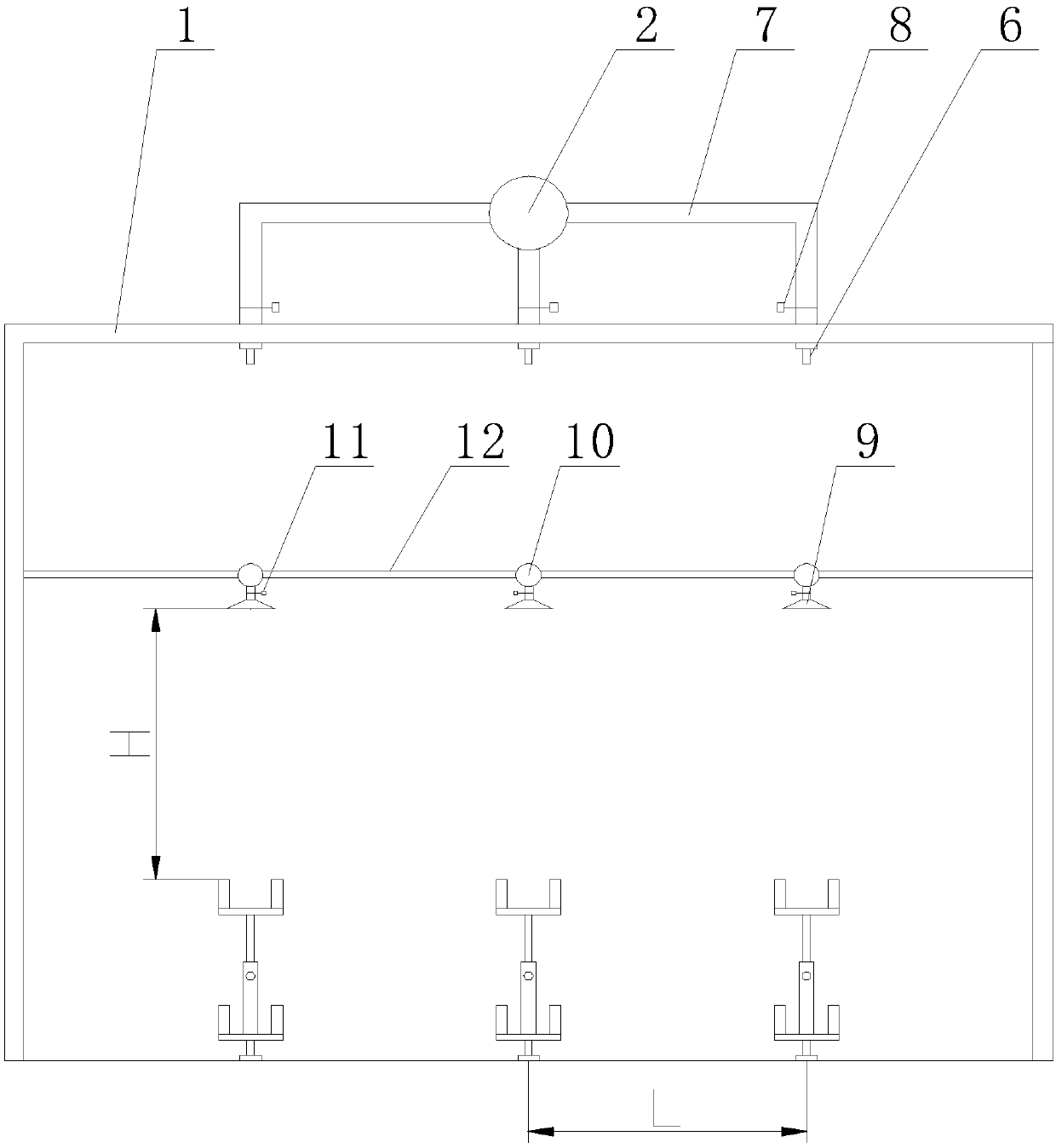

[0015] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a kind of temperature and humidity self-adjusting seedling cultivation greenhouse described in this embodiment includes a greenhouse main body 1, a control system, a hot air main pipe 2, a hot air blower 3, a water delivery main pipe 4, a water pump 5, a plurality of humidity adjustment components, a plurality of Temperature adjustment components and multiple temperature and humidity monitoring mechanisms, the hot air main pipe 2 is installed on the top of the greenhouse main body 1, the air inlet end of the hot air main pipe 2 is connected to the air outlet of the hot air blower 3, and multiple seedlings are evenly distributed on the ground inside the greenhouse main body 1 unit, each of the seedling raising units is sequentially provided with a temperature and humidity monitoring mechanism, a humidity adjustment assembly, and a temperature adjustment assembly from bottom to top,...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the temperature adjustment assembly of a kind of temperature and humidity self-adjusting type seedling raising greenhouse described in this embodiment includes hot air nozzle 6, hot air branch pipe 7 and hot air nozzle solenoid valve 8, hot air nozzle 6 is installed on the top of the greenhouse main body 1, And the nozzle of hot blast nozzle 6 is downward, and hot blast nozzle 6 is connected with hot blast main pipe 2 by hot blast branch pipe 7, and hot blast nozzle solenoid valve 8 is installed on hot blast branch pipe 7, and the control signal input end of hot blast nozzle solenoid valve 8 is connected with the control system. The control signal output terminal is connected. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the humidity adjustment assembly of a kind of temperature and humidity self-adjusting type nursery greenhouse described in this embodiment includes atomization nozzle 9, water delivery pipe 10, atomization nozzle solenoid valve 11 and beam 12, water delivery pipe 10 passes through the beam 12 is installed in the main body 1 of the greenhouse, the atomizing nozzle 9 is installed on the lower surface of the water delivery pipe 10, the water delivery pipe 10 is connected to the outlet end of the water delivery main pipe 4, the atomizing nozzle electromagnetic valve 11 is installed on the atomizing nozzle 9, and the mist The control signal input end of the spray head electromagnetic valve 11 is connected with the control signal output end of the control system. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com