Explosive explosion-proof tube device for thermal analysis experiments

An experimental, explosion-proof cylinder technology, which is applied in the direction of material explosion, can solve the problems of small amount of explosive samples and the inability to simulate blastholes, etc., and achieve the effects of ensuring safety, increasing the amount of explosive samples, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention clearer, the device will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

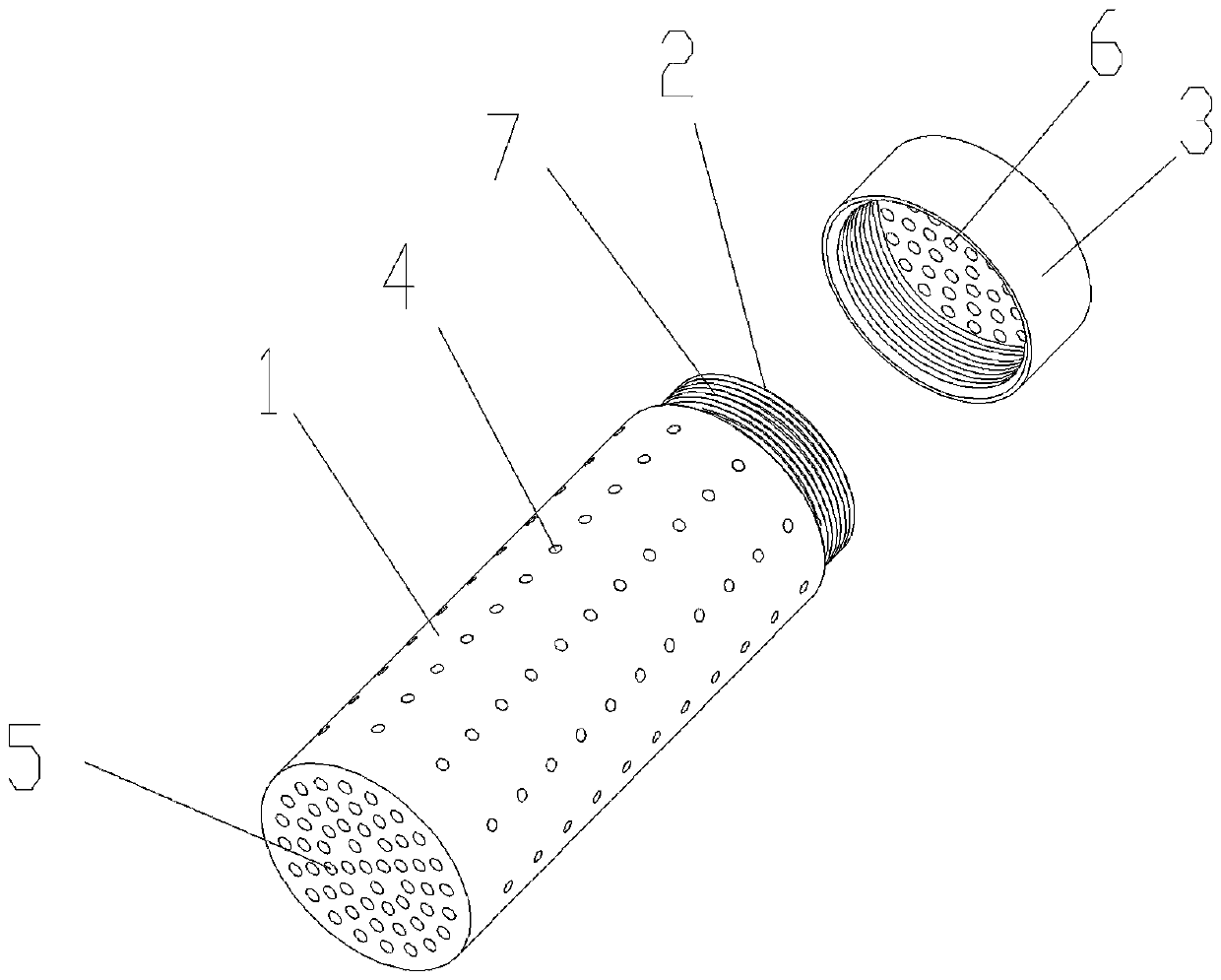

[0015] Such as figure 1 Shown, a kind of thermal analysis experiment provided by the present invention uses explosion-proof cylinder device for explosives, comprises cylinder body 1, and cylinder body 1 is made of the cylindrical cylinder of high-strength stainless steel, and anticorrosion and antirust treatment is carried out on its surface, and the method of processing is In the prior art, the cylinder body 1 is 300-450mm long, the inner diameter is 50-60mm, and the wall thickness is 5-8mm. In this proposal, the cylinder body 1 is 400mm long, the inner diameter is 55mm, and the wall thickness is 6mm.

[0016] One end of the cylinder 1 is provided with an opening 2, and an annular groove 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com