Waste liquid evaporator multi-parameter measuring device and measuring method

A measuring device and evaporator technology, which is applied in the field of nuclear facility waste liquid evaporation treatment and nuclear power plant, can solve the problem that the integrated evaporator cannot arrange the instrument port, etc., and achieve the effect of integrated measurement, mutual interference prevention and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

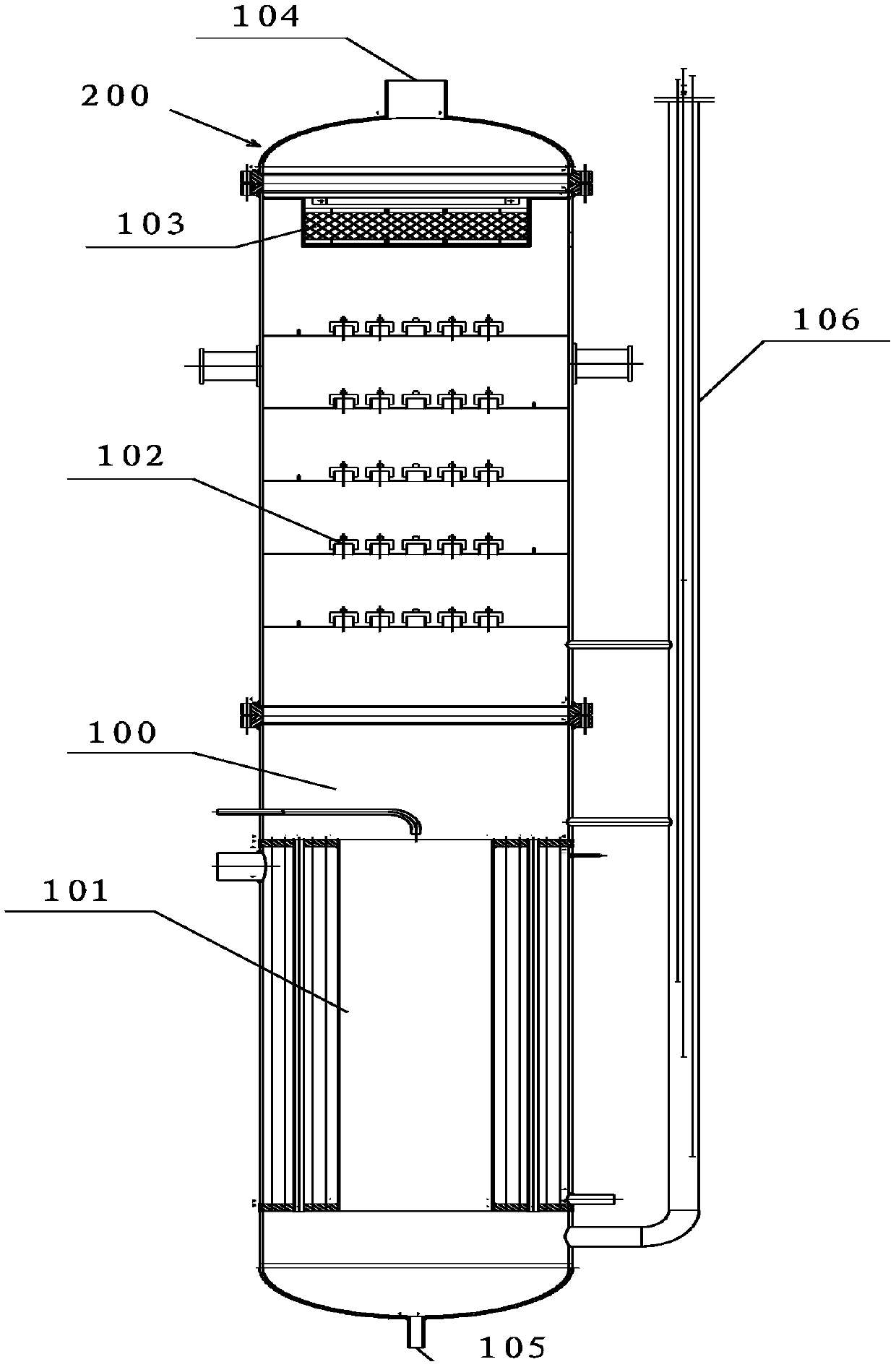

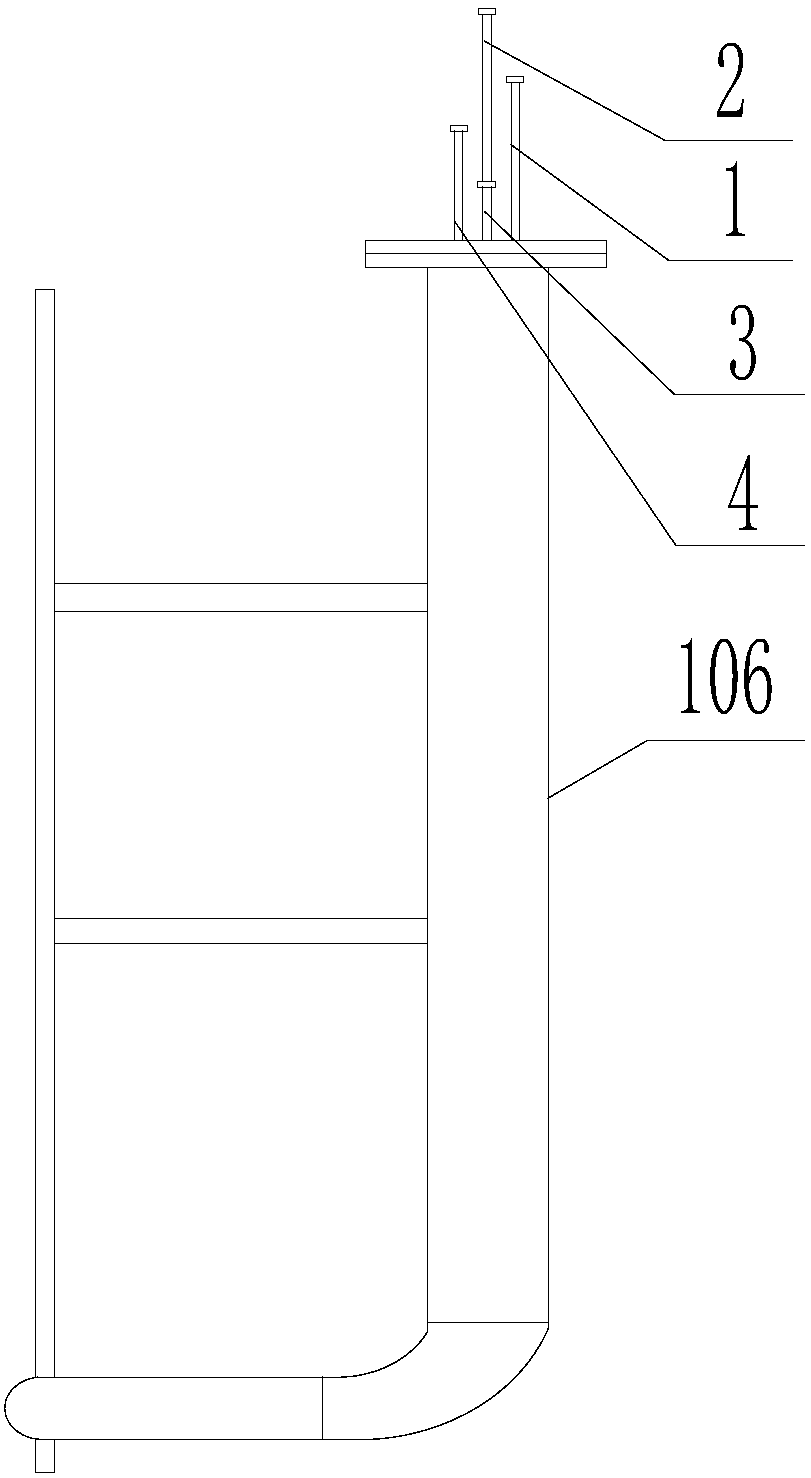

[0044] Example 1:

[0045] Such as Figure 1 to Figure 4 As shown, a multi-parameter measuring device for a waste liquid evaporator includes a bypass pipe 106 communicating with the lower part of the evaporator 200 The evaporator 200 is an integrated steam generator. The integrated steam generator includes a shell. A heating chamber 101, a separation chamber 100, a bubble tower 102, and a wire mesh defoamer are sequentially arranged from bottom to top in the shell. The top and bottom of the housing are respectively provided with a secondary steam outlet pipe 104 and a drain pipe 105, the free end of the bypass pipe 106 is set upward, and the free end of the bypass pipe 106 is provided with A flange, the flange is provided with a first liquid level measuring tube 1, a liquid level measuring tube 3, a density measuring tube 2 and a temperature measuring tube 4, the first liquid level measuring tube 1 The second liquid level measuring tube 3 Density measuring tube 2 And temperat...

Example Embodiment

[0046] Example 2:

[0047] Such as Figure 1 to Figure 4 As shown, this embodiment is based on Embodiment 1. The measuring mechanism further includes a steam cleaning pipe 9 which is divided into 3 branches by a four-way valve, and the 3 branches are connected to the first liquid level measuring pipe. 1. The second liquid level measuring tube 3 and the density measuring tube 2 are connected.

Example Embodiment

[0048] Example 3:

[0049] Such as Figure 1 to Figure 4 As shown, this embodiment is based on Embodiment 1. The bypass pipe 106 and the evaporator 200 are in three-stage communication, the first-stage communication is that the bypass pipe 106 communicates with the heating chamber 101, and the first-stage communication mode is bypass. The through pipe 106 is directly welded to the evaporator 200 of the evaporator device. The second level of communication is that the bypass pipe 106 communicates with the lower part of the separation chamber 100, and the third level of communication is that the bypass pipe 106 communicates with the upper part of the separation chamber 100; The method is that the bypass pipe 106 and the separation chamber 100 are connected in a flange type.

[0050] Example 3:

[0051] Such as Figure 1 to Figure 4 As shown, this embodiment is based on embodiment 1, the first liquid level measuring tube 1, the second liquid level measuring tube 3, the density measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com