Automatic oil supply line based on microprocessor control

A microprocessor and oil supply technology, applied in signal processing, lubricating oil control valve, engine components, etc., can solve the problems of no delay function, low degree of automation, shaft and bearing damage, etc., to achieve simple structure and degree of automation High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

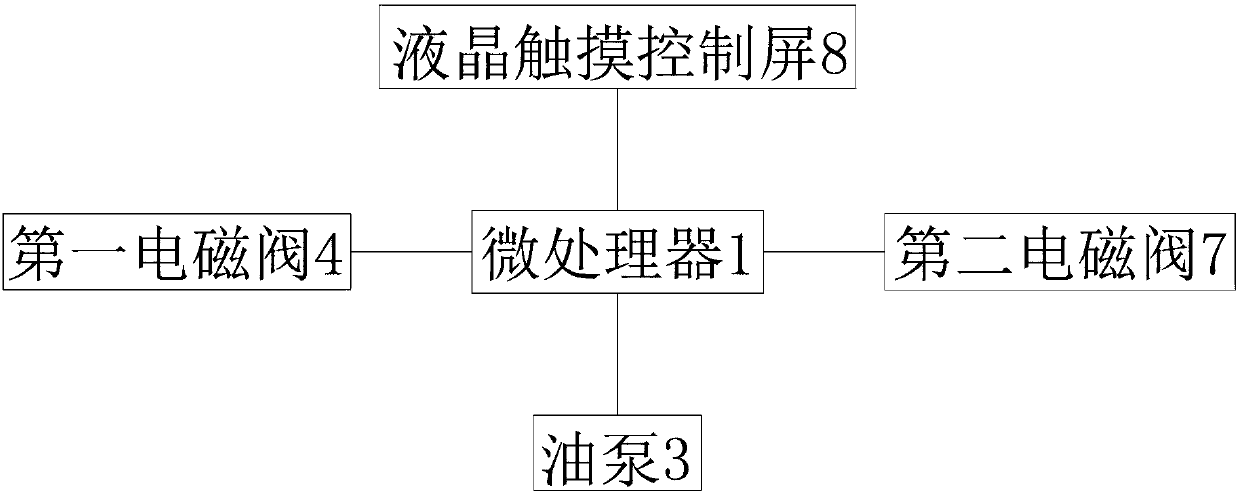

[0016] Such as figure 1 and 2 As shown, an automatic oil supply circuit based on microprocessor control has simple structure, scientific and reasonable design, convenient use, delay function, energy saving and high degree of automation. The present invention includes a microprocessor 1, and a first filter 2, an oil pump 3, a first solenoid valve 4, and an accumulator 5, which are all arranged on the oil supply line and distributed sequentially from the oil inlet to the oil outlet. , the second filter 6 and the second solenoid valve 7, the microprocessor 1 is electrically connected with the oil pump 3, the first solenoid valve 4 and the second solenoid valve 7 respectively, the microprocessor 1 It is also electrically connected with a liquid crystal touch control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com