Conical shell type water tower cast-in-situ supporting structure

A technology for supporting structures and water towers, which is applied to the preparation of pillars, building structures, and building components on site. It can solve the problems of high cost and long construction period, and achieve the effects of easy pouring, increased strength, and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

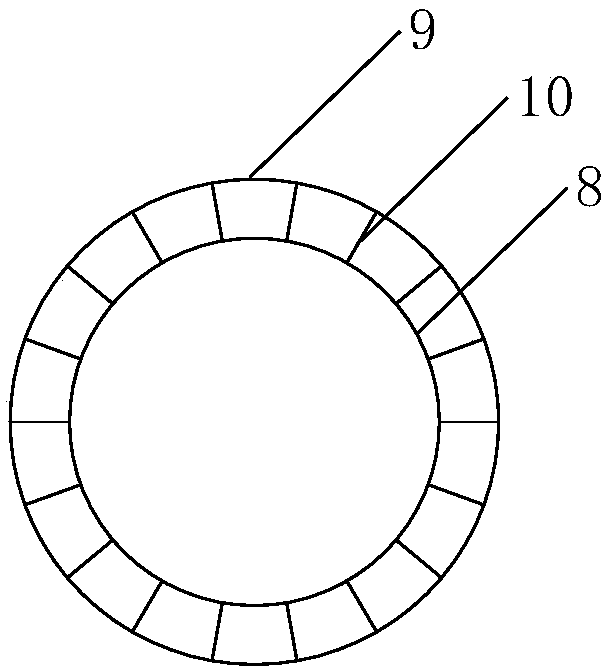

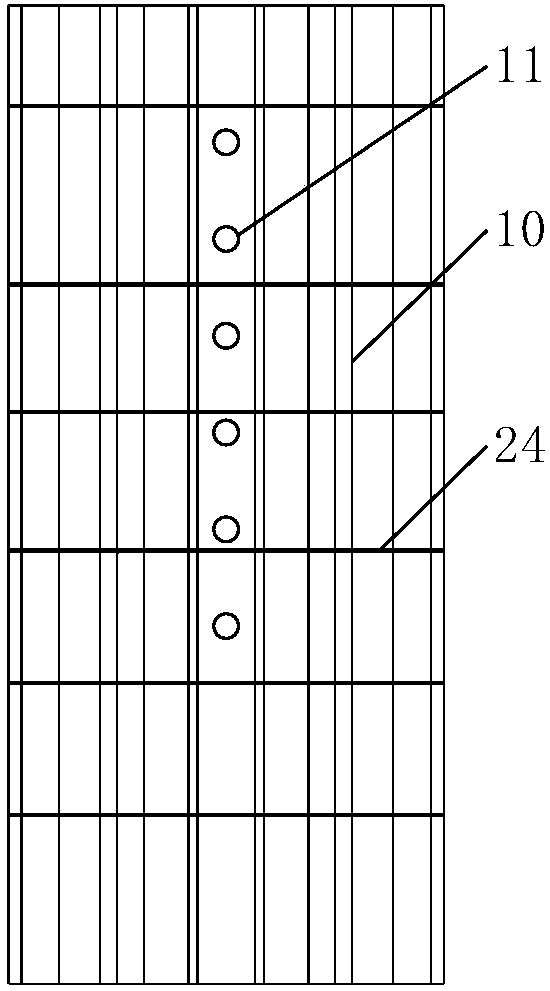

[0027] See Figure 5 , Figure 6 , a conical shell type water tower cast-in-place support structure, including a support tube 1, a steel bar 2, a ring support 3, a hanger 4, a suspension 5, a supporting steel beam 6, a derrick 7, a water tank formwork 21, a cable 16, a ring Plate 12; the ring support 3 and the top of the support tube 1 are fixed by steel bars 2, the section of the ring support 3 is inverted L-shaped, and the support tube 1 below the ring support 3 is fixed with a ring plate 12, and the ring support 3 and the ring support The plate 12 is fixedly supported by the reinforcing rib 13, the hanger 4 is welded and fixed to the top of the ring support 3, the suspension 5 is fixedly connected to the hanger 4; the supporting steel beam 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com