Novel low-position water draining body suitable for ultra-low-position vacuum pre-pressing method

A vacuum preloading method and drainage body technology, which is applied in soil protection, construction, and infrastructure engineering, etc., can solve problems such as unsatisfactory reinforcement effects, easy inward deformation, and poor drainage, so as to improve drainage efficiency and avoid The effect of weakening the underlying layer and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

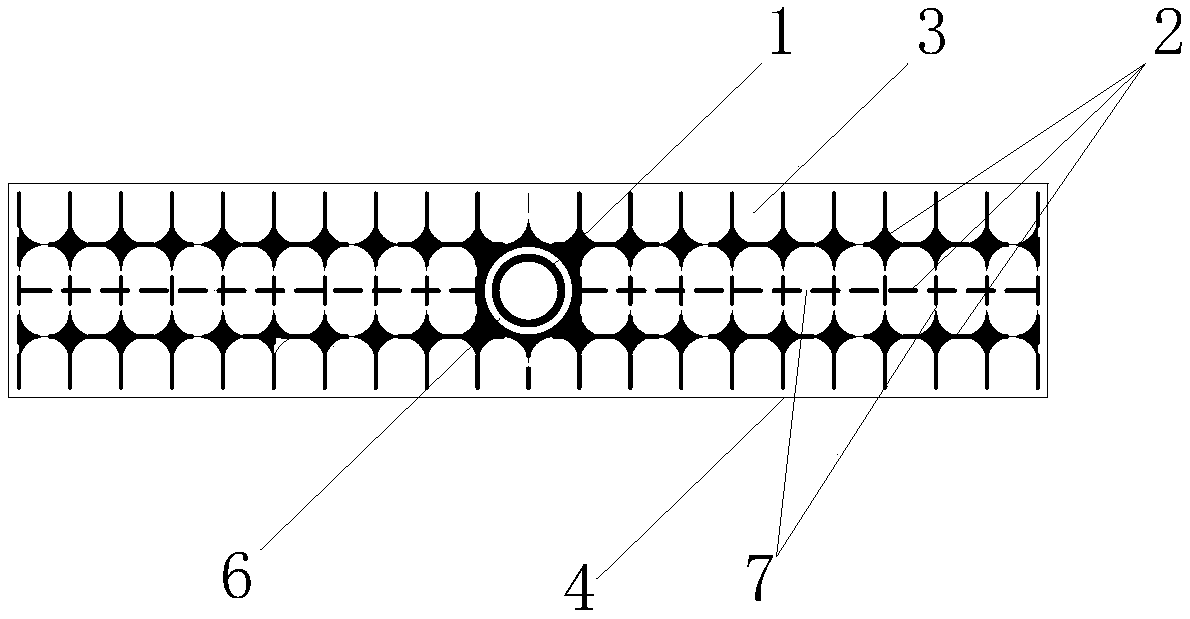

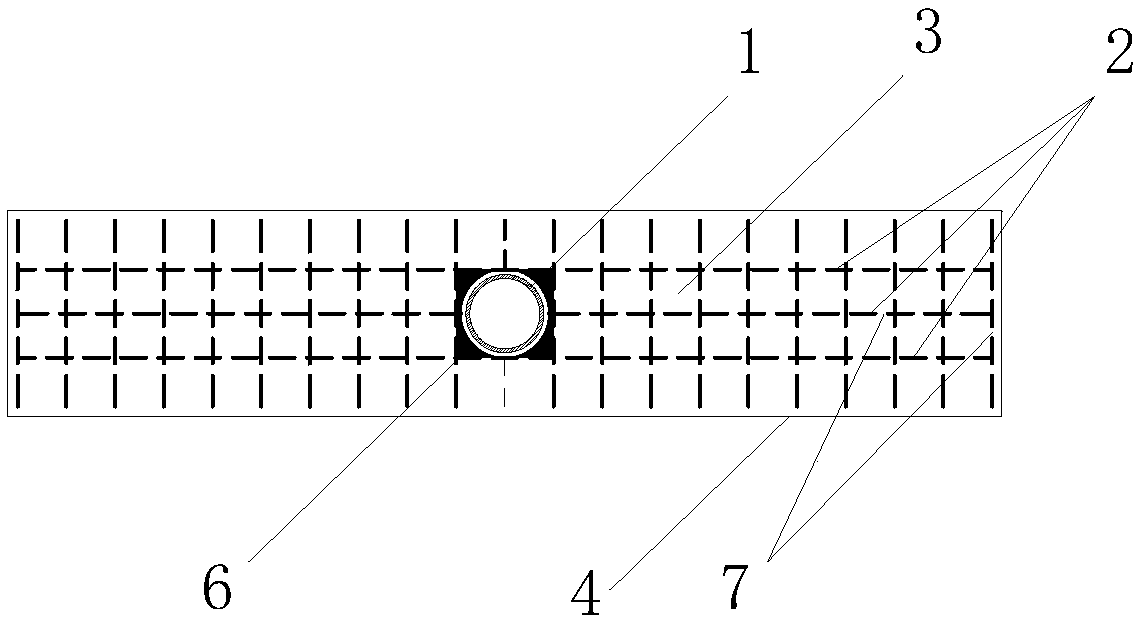

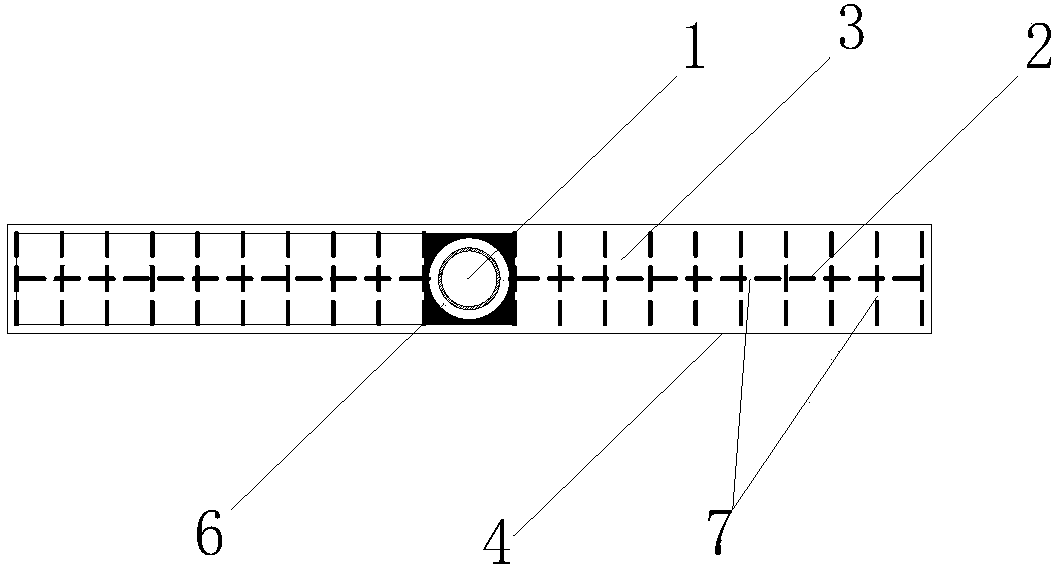

[0030] Such as Figure 1-4 Shown: a new type of low-level drainage body suitable for ultra-low vacuum preloading method. The drainage body adopts a space lattice dragon skeleton, and the internal space part forms a drainage channel and a vacuum transmission channel. The dragon skeleton body is equipped with a water inlet Holes and vacuum transmission holes, a vacuum conduction tube hole is reserved at the centroid of the cross-section of the dragon skeleton, the vacuum conduction tube is embedded in the vacuum conduction tube hole and connected with the space lattice dragon skeleton through the lower end to realize the vacuum load from the vacuum conduction tube The transmission diffuses to the vacuum transmission channels in the space lattice dragon skeleton of the drainage body, and further diffuses into the reinforced soil through the vacuum transmission holes. The above-mentioned space lattice type dragon skeleton is wrapped with a water-filtering non-woven fabric. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com