Vehicle lifting jack used in transportation field

A technology in the field of lifts, which is applied in the field of vehicle lifts, can solve the problems of high suspension suspension, high center of gravity of the vehicle, time-consuming and labor-intensive problems, and achieve the effects of avoiding rollover, convenient lifting, and convenient carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

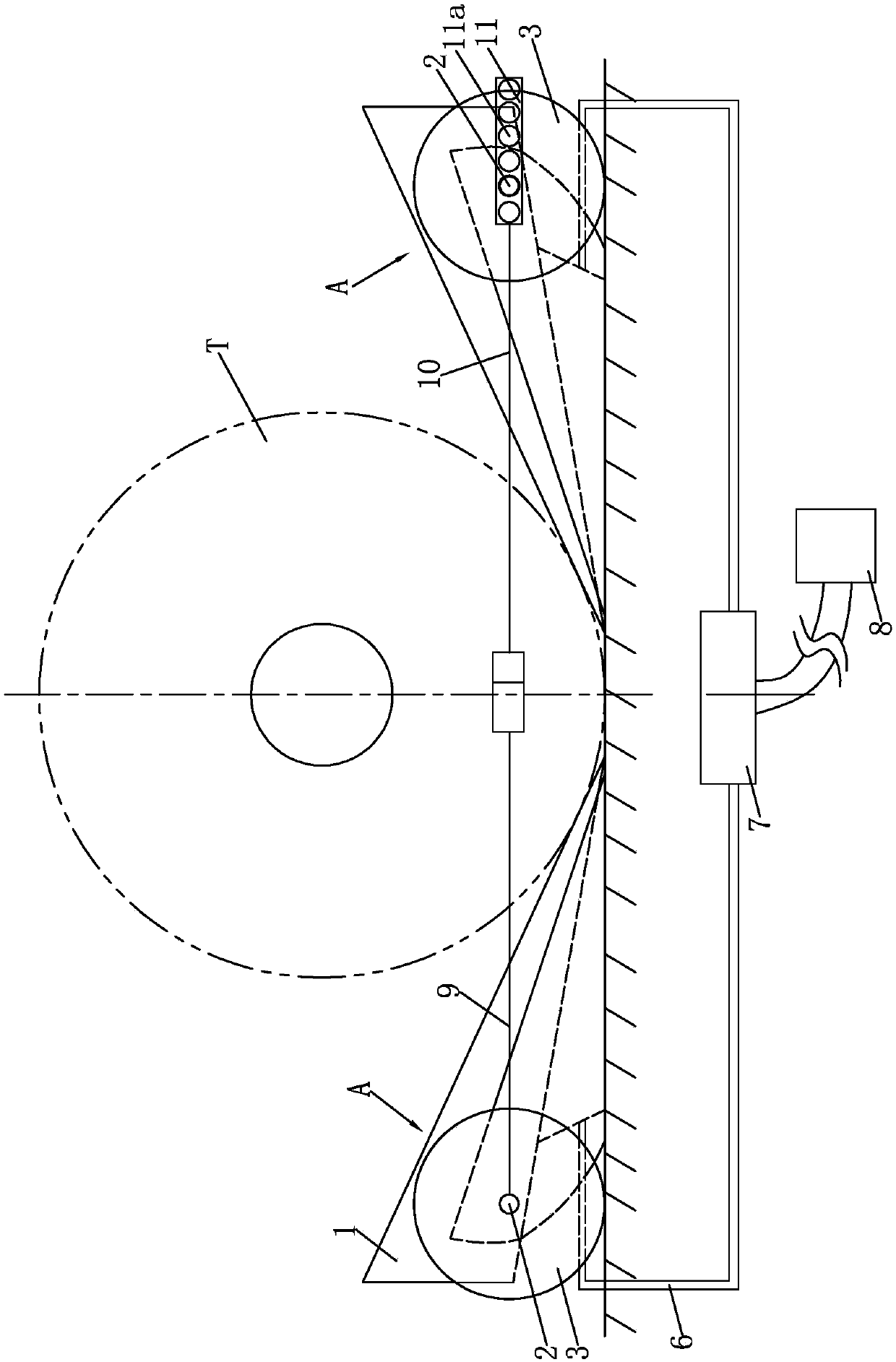

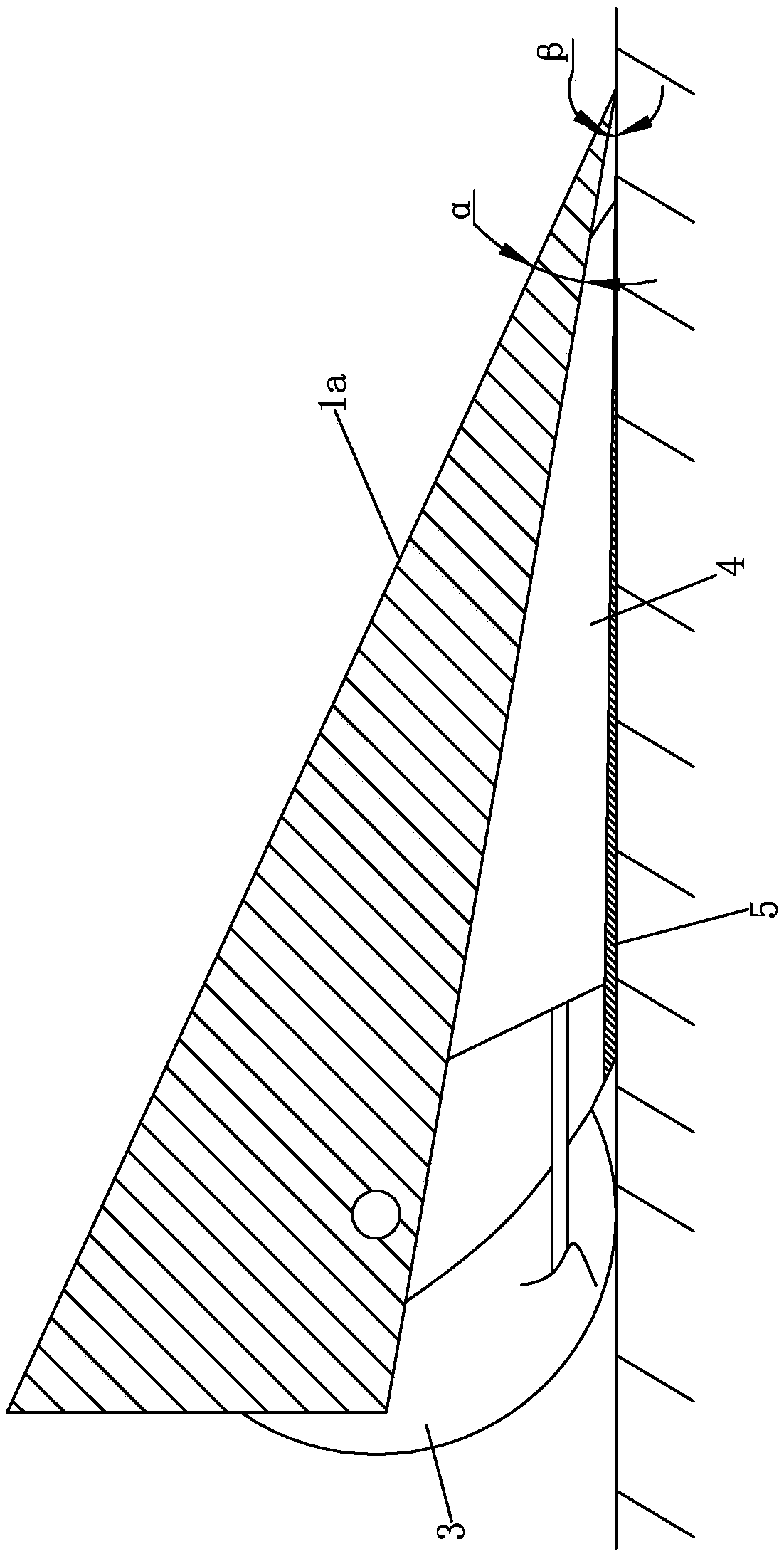

[0021] Such as figure 1 , 2 As shown, a vehicle lift used in the traffic field is mainly composed of a lifting trolley A and a tensioning device. Wherein, the lifting trolley A is mainly composed of a tire lifting plate 1, a support wheel fixed shaft 2, a support wheel 3, a lift air bag 4 and a support steel plate 5. Wherein, the tire lifting plate 1 is a steel plate, and the cross section of the tire lifting plate 1 is an obtuse triangle. The obtuse angle place bottom of tire lifting plate 1 is fixedly provided with a support wheel fixed shaft 2, and this support wheel fixed shaft 2 is a steel shaft, and its diameter is 3-6mm. A support wheel 3 is respectively rotated at the front and rear ends of the support wheel fixed shaft 2, and the diameter of the support wheel 3 is 40-80cm, and can be further preferably 50, 60 or 70cm, and the support wheel 3 is su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com