Spray room roller bed

A technology of roller bed and spray booth, which is applied in the direction of roller table, conveyor, transportation and packaging, etc. It can solve the problems of complex structure of tensioning components, high motor requirements, poor transmission effect, etc., and achieve better tensioning effect, The effect of scraping paint thoroughly and taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

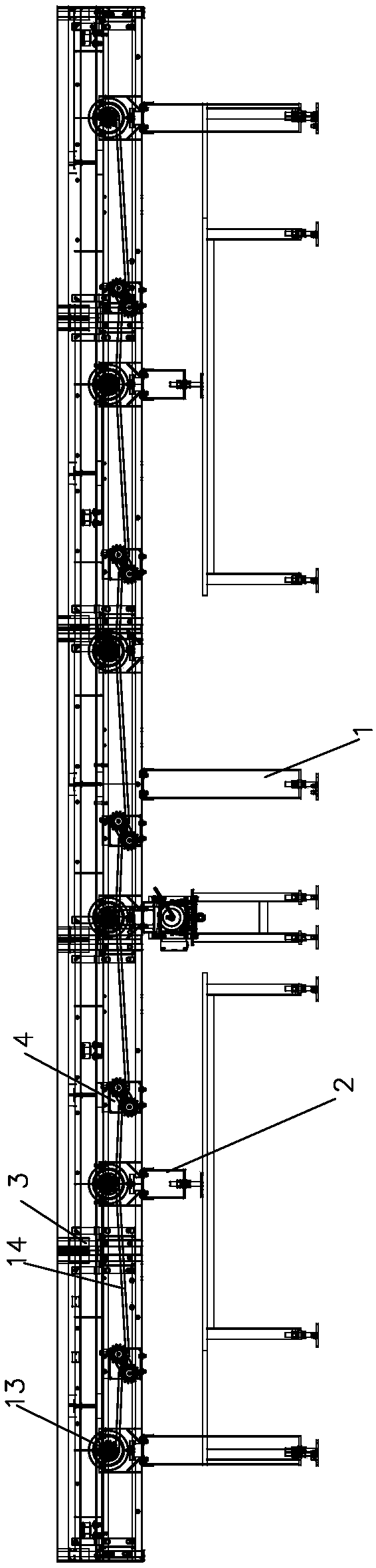

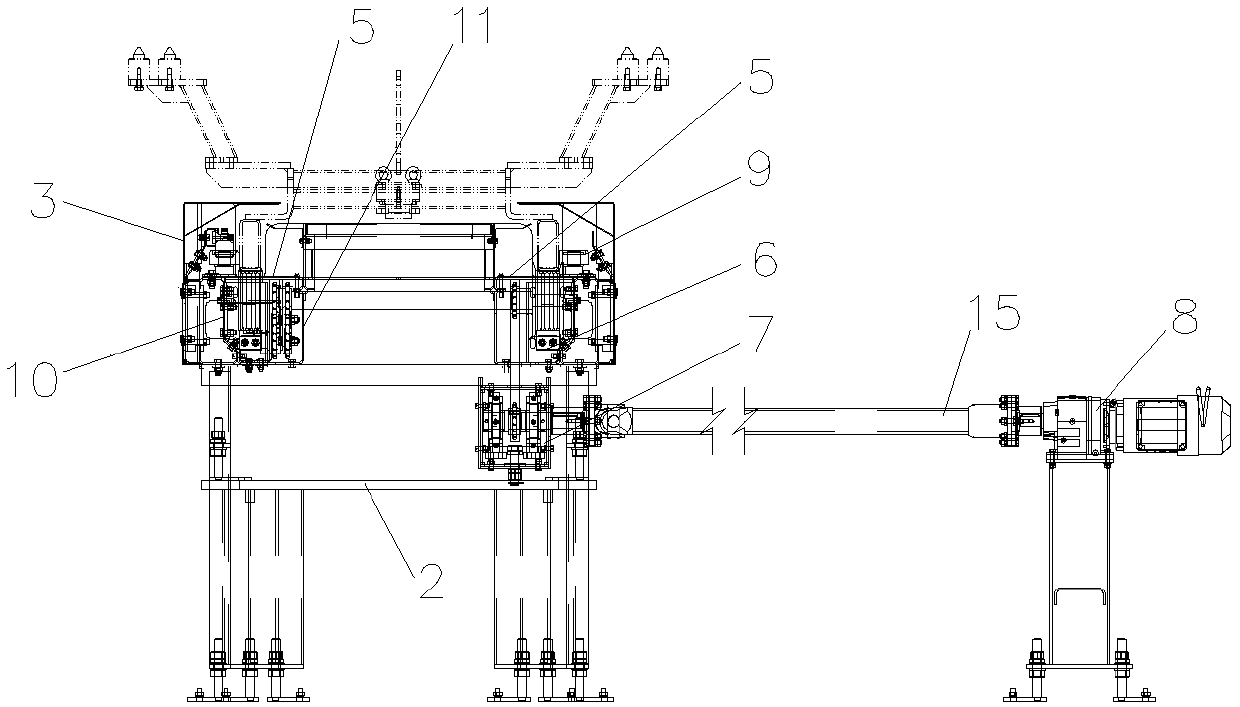

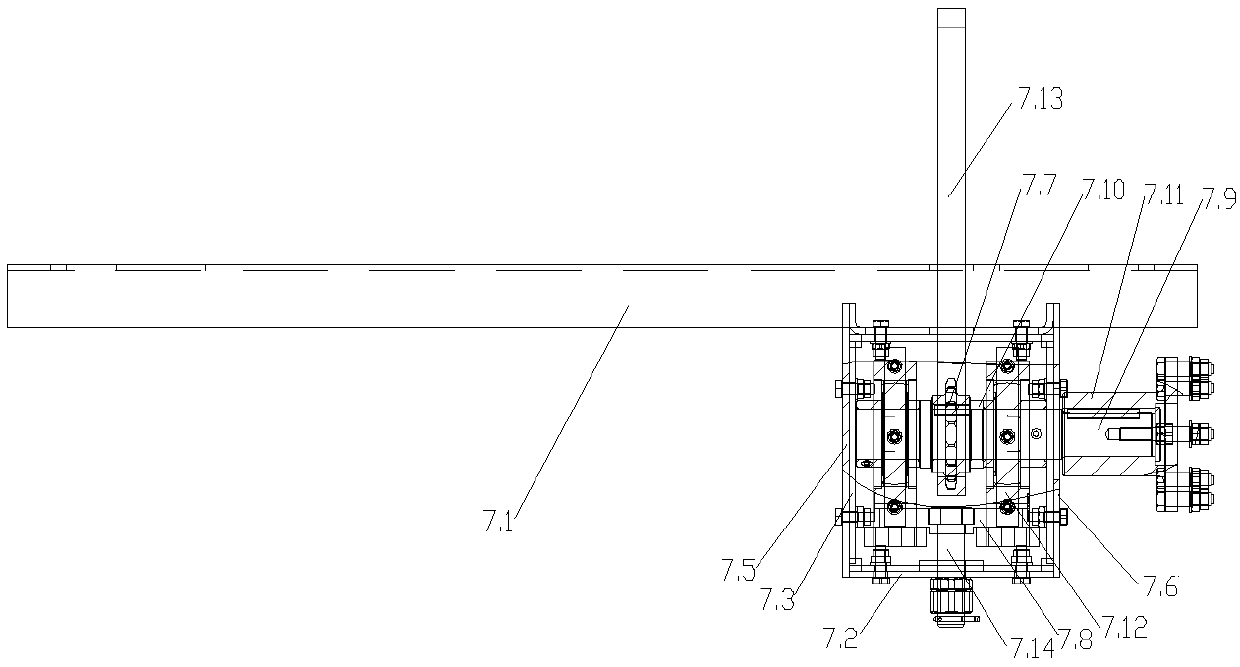

[0031] Such as Figure 1-3 Shown: spray booth roller bed, including outer cover plate assembly 3, roller 13 and drive assembly 8, a plurality of rollers 13 are arranged in parallel in the outer cover plate assembly 3, and an independent chain 14 is respectively arranged between two adjacent rollers 13 , each chain 14 is respectively connected with sprockets installed on two adjacent rollers 13, and each chain 14 is provided with a tensioning assembly 4. A paint scraper assembly 6 is provided under the pulleys at both ends of the roller 13 . The drive assembly 8 is connected to one of the rollers 13 by means of the drive tension assembly 7 .

[0032] Side plates 10 are installed in the side walls of the outer cover plate assembly 3 , and the two ends of the rollers 13 are installed on the side plates 10 on both sides. The upper end of the side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com