A belt tensioner

A technology of tensioning device and belt, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of inconvenient operation, increase belt wear, affect the transmission effect, etc., so as not to affect the transmission effect, reduce the The effect of belt wear and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

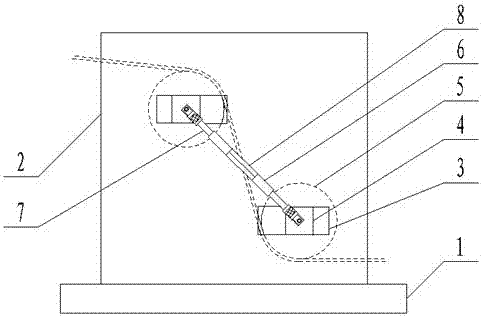

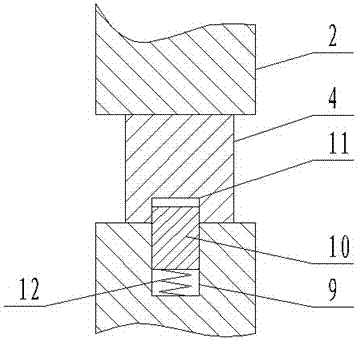

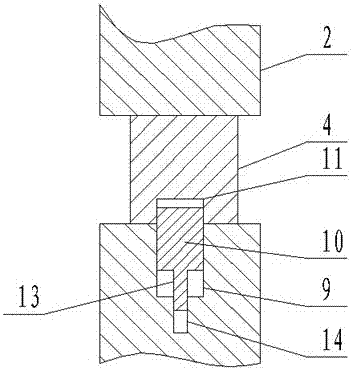

[0018] Such as Figure 1 to Figure 3 As shown, a belt tensioning device in this specific embodiment includes a bottom plate 1, on which two opposite and vertical support plates 2 are arranged, and the two support plates 2 are opposite and each Two strip-shaped through-holes 3 arranged in parallel are provided, and the strip-shaped through-hole 3 is provided with an inner wall that can move along the length direction of the strip-shaped through-hole 3 and is slidably matched with the two side walls of the strip-shaped through-hole 3 respectively. The sliding seat 4, the said bar-shaped through hole 3 is also provided with a limit guide for limiting the sliding of the said sliding seat 4 from the said bar-shaped through hole 3, and two said support plates 2 are provided There are two horizontal and parallel tensioning shafts 5, the two ends of the tensioning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com