cosmetic liquid storage bottle

A technology of cosmetic liquid and liquid discharge port, which is applied in the field of daily necessities, can solve the problems of inconvenient carrying, large space occupation, and easy collision, etc., and achieve the effect of convenient portability and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

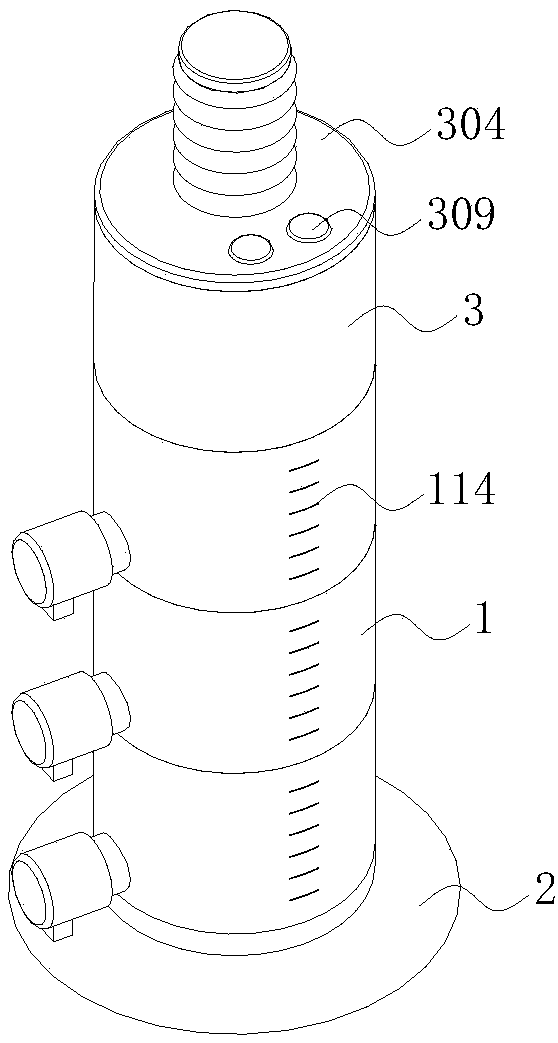

[0042] See attached figure 1 - attached Figure 7 , a cosmetic liquid storage bottle of the present invention comprises:

[0043] A plurality of detachably connected containing boxes 1 arranged up and down in sequence, each containing box 1 includes a box body 101, a piston 102 slidingly fitted with the inner wall of the box body 101, and a guide rod 104 vertically fixed on the upper end of the piston 102; the piston 102 The box body 101 is divided into an upper pressure relief chamber 105 and a lower discharge chamber 106, a pressure relief hole 103 connecting the pressure relief chamber 105 and the discharge chamber 106 is opened on the piston 102, and a through hole is opened on the lower end surface of the box body 101 , the lower end of the side wall has a protruding structure, and the lower end of the protruding structure has a liquid discharge port 111, and the protruding structure is connected to a liquid discharge structure; the guide rods 104 located at the bottom o...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is:

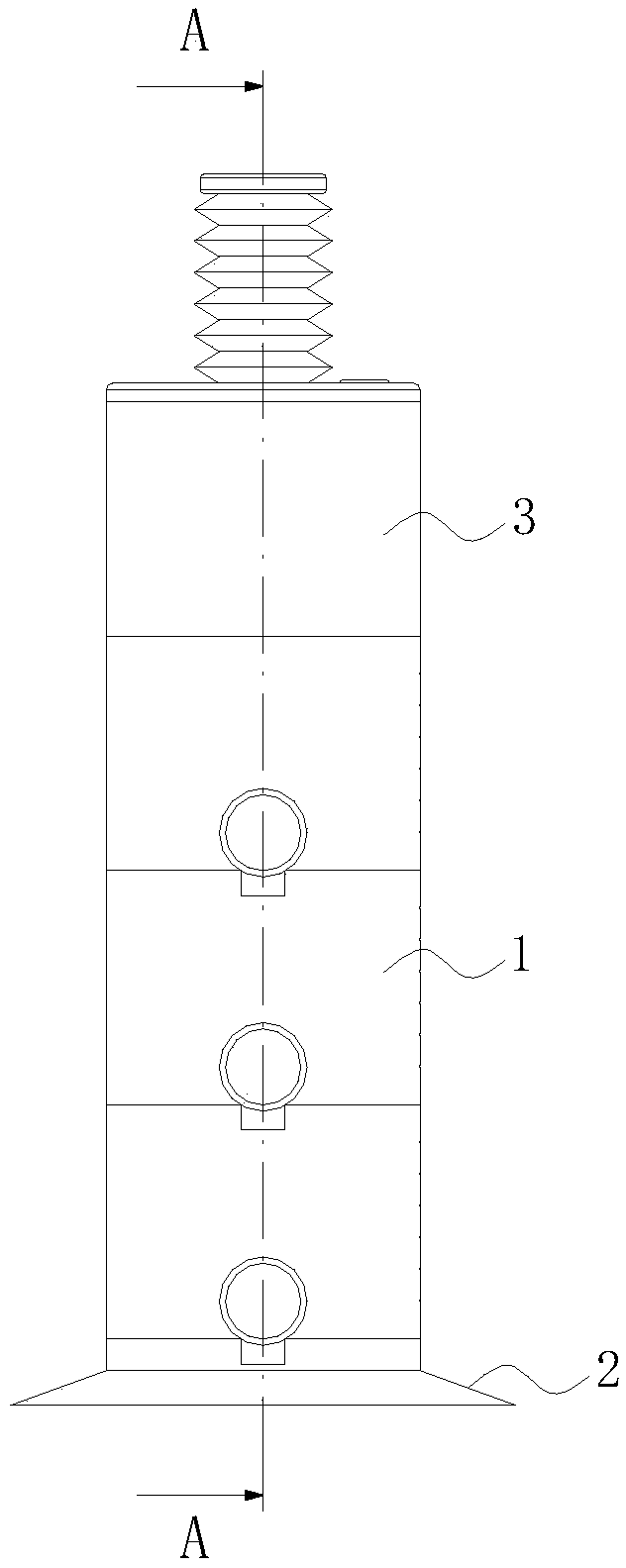

[0064] The control unit 3 includes:

[0065] A control box 301 detachably connected to the uppermost box body 101 of a plurality of storage boxes 1, the lower end of the control box 301 has a through hole, and is matched with the uppermost guide rod 104;

[0066] The upper cover 304 that is arranged on the upper end of the control box 301;

[0067] The lower end passes through the upper cover 304 and the T-shaped pressing rod 302 that is in contact with the upper end of the guide rod 104 extending into the control box 301;

[0068] And a recovery structure arranged between the cross bar of the T-shaped pressing bar 302 and the upper end surface of the upper cover 304 .

[0069] The recovery structure includes a bellows 305 and a return spring 306 sleeved on the T-shaped pressing rod 302 .

[0070] The application process of the present invention is as follows: select a corresponding number of storage boxes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com