Pipe pile automatic uncovering mold system

A technology of pipe piles and cover molds, applied in the field of uncovering systems, can solve the problems of inconvenient installation and maintenance, low efficiency, etc., and achieve the effects of facilitating maintenance and maintenance, improving use efficiency, and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

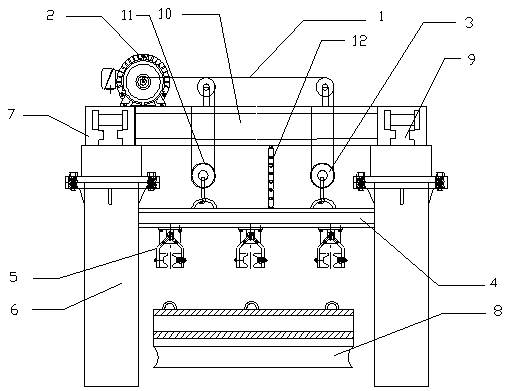

[0015] Such as figure 1 A pipe pile automatic uncovering mold system is shown. The pipe pile automatic uncovering mold system is installed on the pipe pile conveyor belt. The pipe pile automatic uncovering mold system includes; steel wire rope 1, wire rope motor 2, steel wire roller 3, Cover beam 4, mechanical hook 5, support column 6 and support beam 7.

[0016] The support column 6 and the support beam 7 form a door frame structure, which is perpendicular to the pipe pile conveyor belt 8, the support column 6 is placed on both sides of the pipe pile conveyor belt 8, and the support beam 7 is perpendicular to the top of the support column 6 and crosses The pile conveyor belt 8 is provided with a pulley guide rail 9 on the upper end of the support beam 7, and a pulley is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com