Method and apparatus for forming marbelized engineered stone

A device, computer processor technology, applied in chemical instruments and methods, patterns imitating natural patterns, manufacturing tools, etc., can solve problems such as lack of color patterns and textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

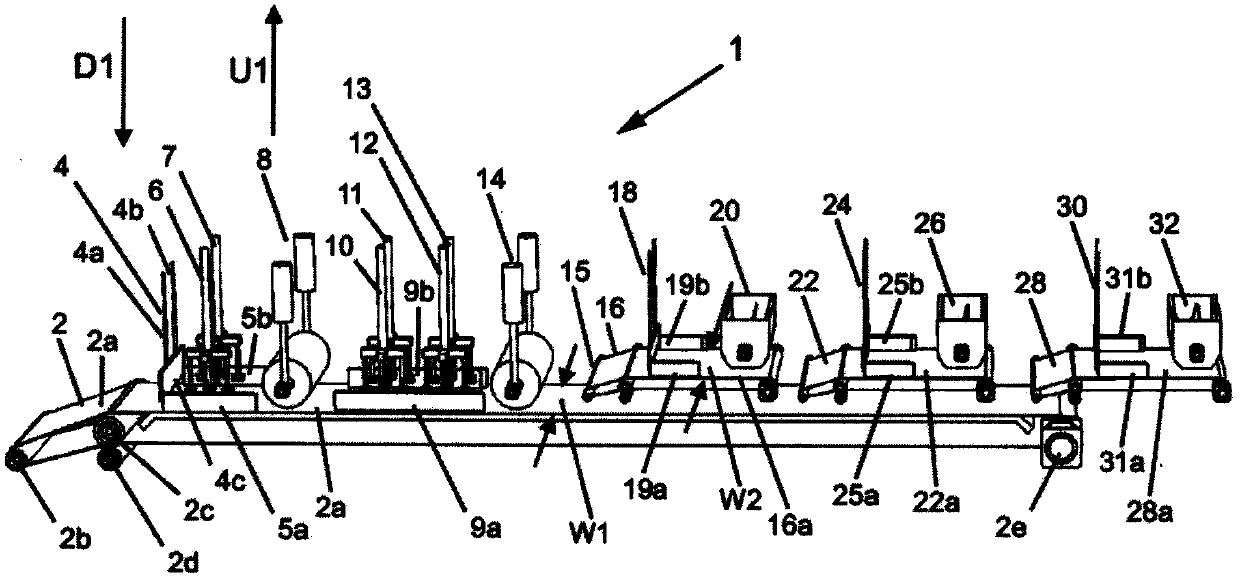

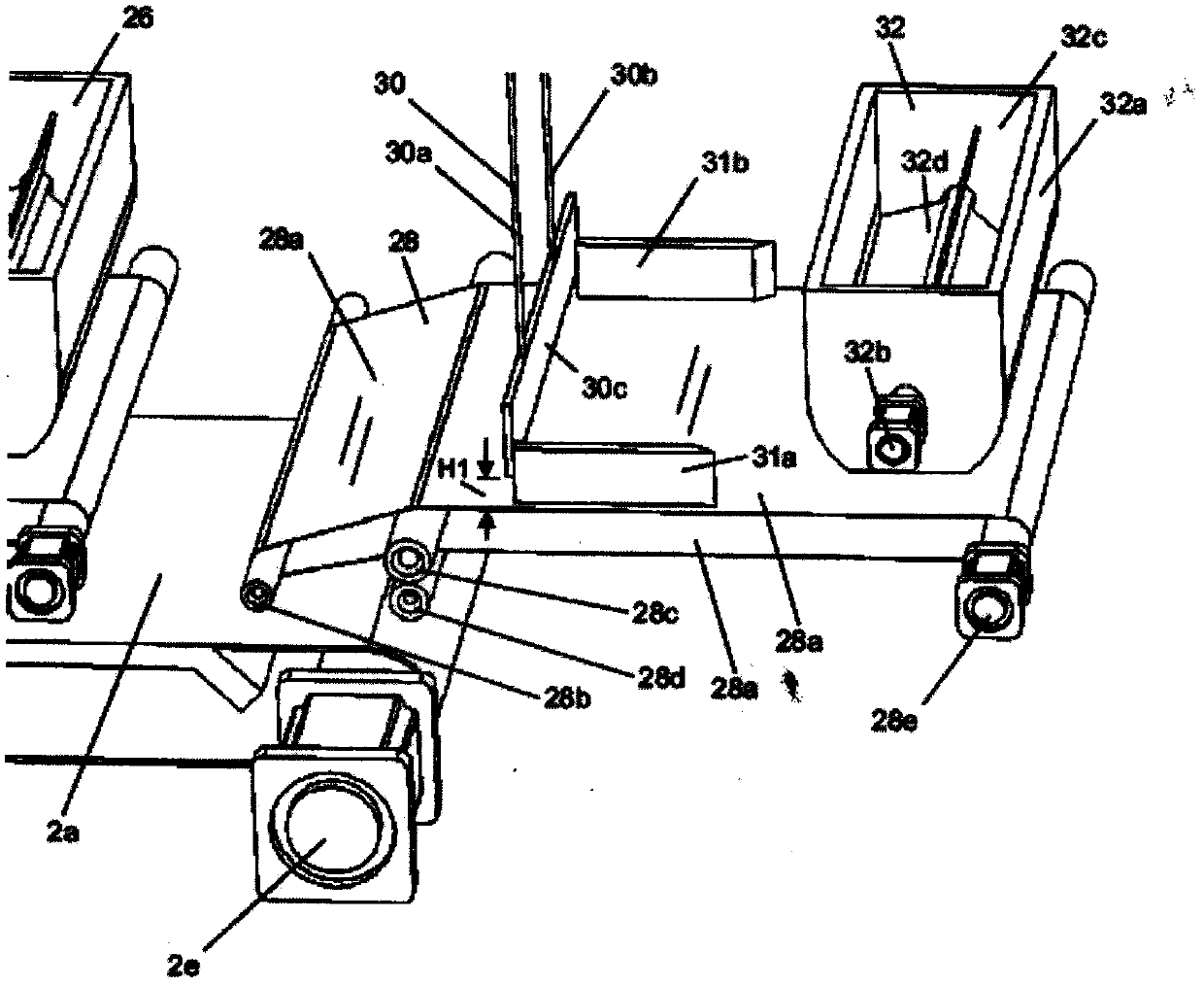

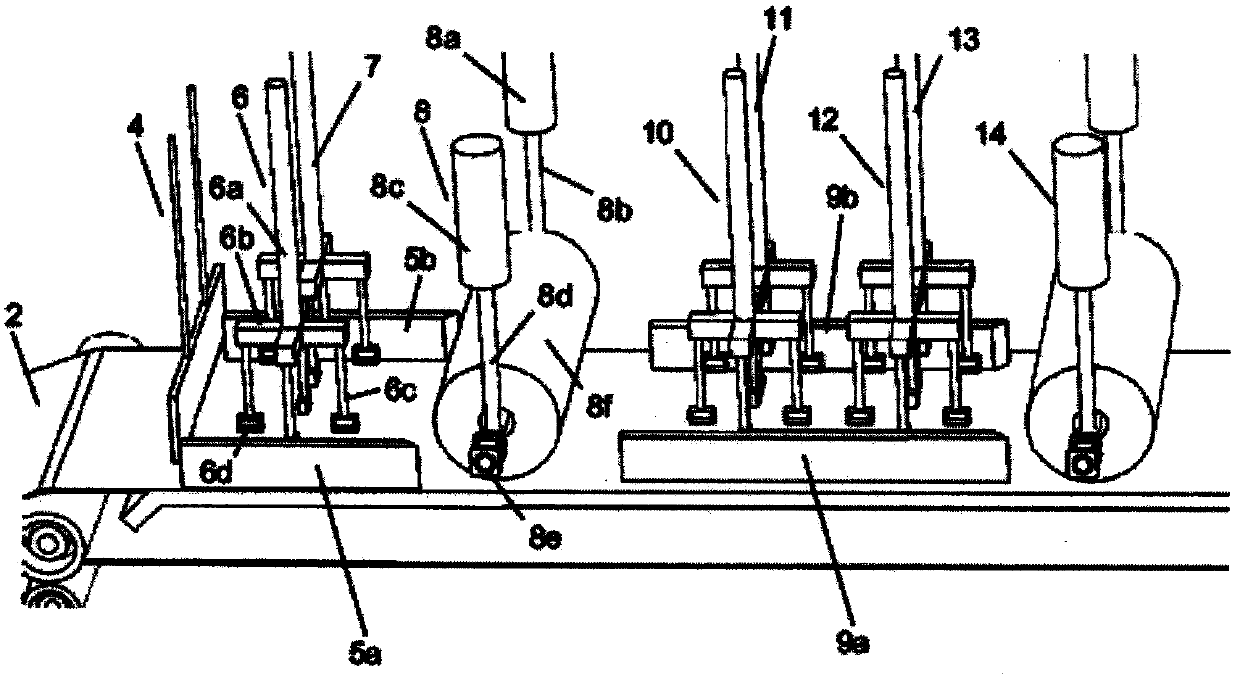

[0075] Now in conjunction with the accompanying drawings, the present invention will be described in further detail. A device 1 such as figure 1 As shown, it comprises a main conveying device 2, a main door device 4 with a gate, walls 5a and 5b, a second stirring device 6 and 7, a second rolling device, which can use a roller device 8, a first stirring device 10, 11, 12 and 13, walls 9a and 9b, first rolling means, possibly roller means 14, third auxiliary conveying means 16, third auxiliary gate means with gates 18, walls 19a and 19b, second Three distributing means 20, second auxiliary conveying means 22, second auxiliary gate means with gates 24, walls 25a and 25b, second distributing means 26, first auxiliary conveying means 28, first auxiliary gate means with gates 30 , walls 31 a and 31 b and first distribution means 32 .

[0076] The communication connection between the above-mentioned means in the device 1 and the computer processor, such as Figure 11 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com