Lamp pole longitudinal joint welding mechanism

A welding and lamp pole technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of cost, difficulty in ensuring the distance between welding wire and welding seam, difficulty in operation, etc., and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

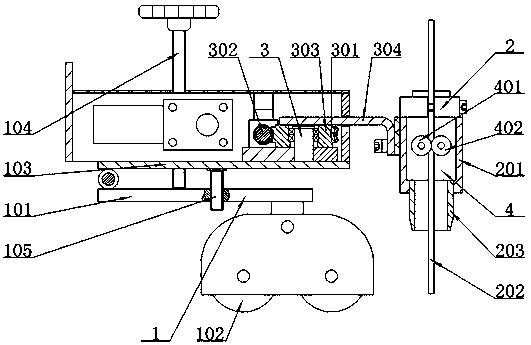

[0014] like figure 1 As mentioned above, it is a light pole longitudinal seam welding mechanism, which includes a guide mechanism 1 located in the light pole to be welded and a weld seam mechanism 2 connected to the guide mechanism 1. In order to ensure that the welding wire 202 reaches the welding seam during the welding The welding seam mechanism 2 includes a housing 201, the lower port of the housing 201 is connected with a welding tip 203 for positioning the welding wire 202, and the housing 201 is provided with a wire feeding mechanism 4, in order to ensure that the welding wire 202 reaches the welding seam during the welding process. The distance between them remains unchanged to ensure that the welding seam mechanism 2 works reliably. The wire feeding mechanism 4 includes active feeding wheels 401 and driven feeding wheels 402 that cooperate with each other. The active feeding wheels 401 are connected through the transmission of the wire feeding motor. Rolling with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com