Automatic pressure-reducing type bobbin loader

A wire reel rack and disc-shaped technology, which is applied in the field of self-decompression type reel rack, can solve the problems of uneven force on the boom of a crane, reduced work efficiency, inconvenient transportation, etc., and achieves a simple structure and reduced safety hazards. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

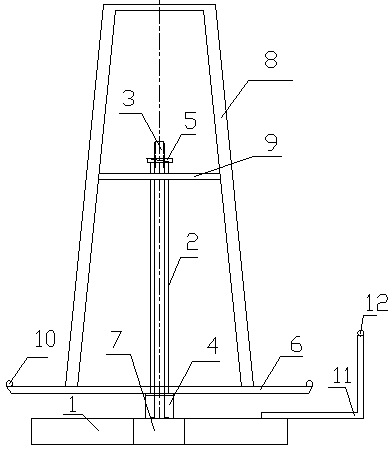

[0011] A self-decompression wire reel rack, combined with an attached figure 1 , mainly including a disc-shaped bottom plate (1) and a reel wound with steel wires, the center of the bottom plate (1) is fixed with a hollow protective column (2), and the protective column (2) and the bottom plate (1) are Connected structure, the reel is a round table (8) hollowed out inside, the lower bottom surface of the round table (8) is designed as an opening, and the inside of the reel is provided with a connecting frame (9). The rotating shaft (3) is installed inside the protective column (2), and one end is fixedly connected with the plane bearing (4), and the other end is fixedly connected with the reduction rotating shaft (5) through a nut. The upper end of the plane bearing (4) is fixed to the bottom plate (1), and the lower end of the plane bearing (4) is installed on the base (6) and connected with the rotating motor (7) inside the base (6). The lower bottom surface of the round ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com