Chassis device conveniently separated from seat

A chassis and seat technology, which is used in transportation and packaging, vehicle rescue, patient chairs or special transportation tools, etc., can solve the problems of large assembly workload, increased transportation costs, and complicated connections, and achieves a slot-frame structure. The effect of simplicity, lower production cost and compact box structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

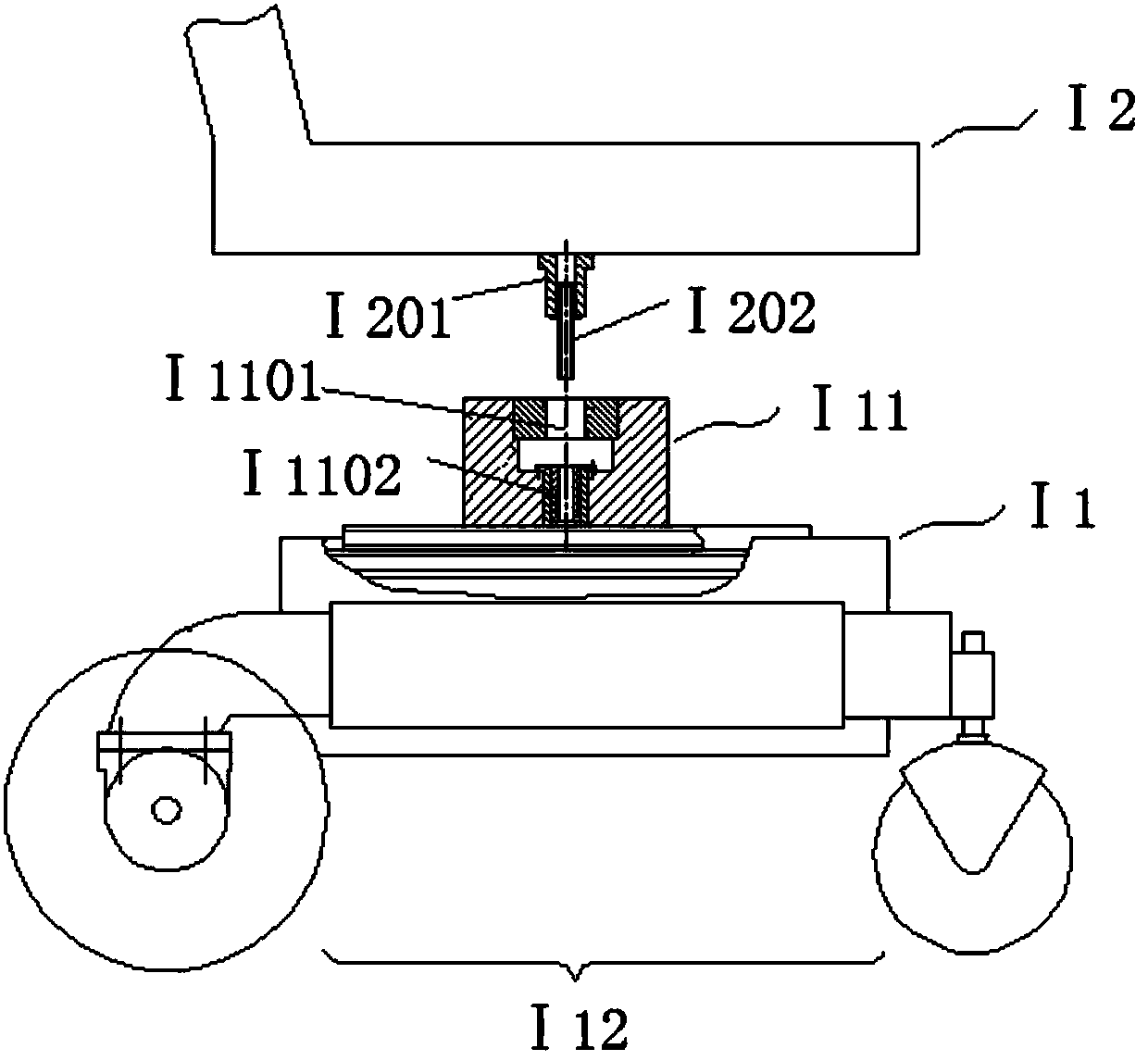

[0064] Such as figure 1 As shown, the chassis device I1 of the present invention includes an electric traveling mechanism I12 and a base I11 arranged above the electric traveling mechanism I12. A support hole I1101 is provided on the upper surface of the base I11, and a multi-core socket I1102 is provided below the support hole I1101. The upper seat device I2 is inserted into or pulled out of the support hole I1101 through the insertion shaft I201 provided below, and at the same time, the multi-core plug I202 provided at the lower end of the insertion shaft I201 is inserted into or pulled out of the multi-core socket I1102 on the base to connect with the chassis device Ⅰ1 connection or separation.

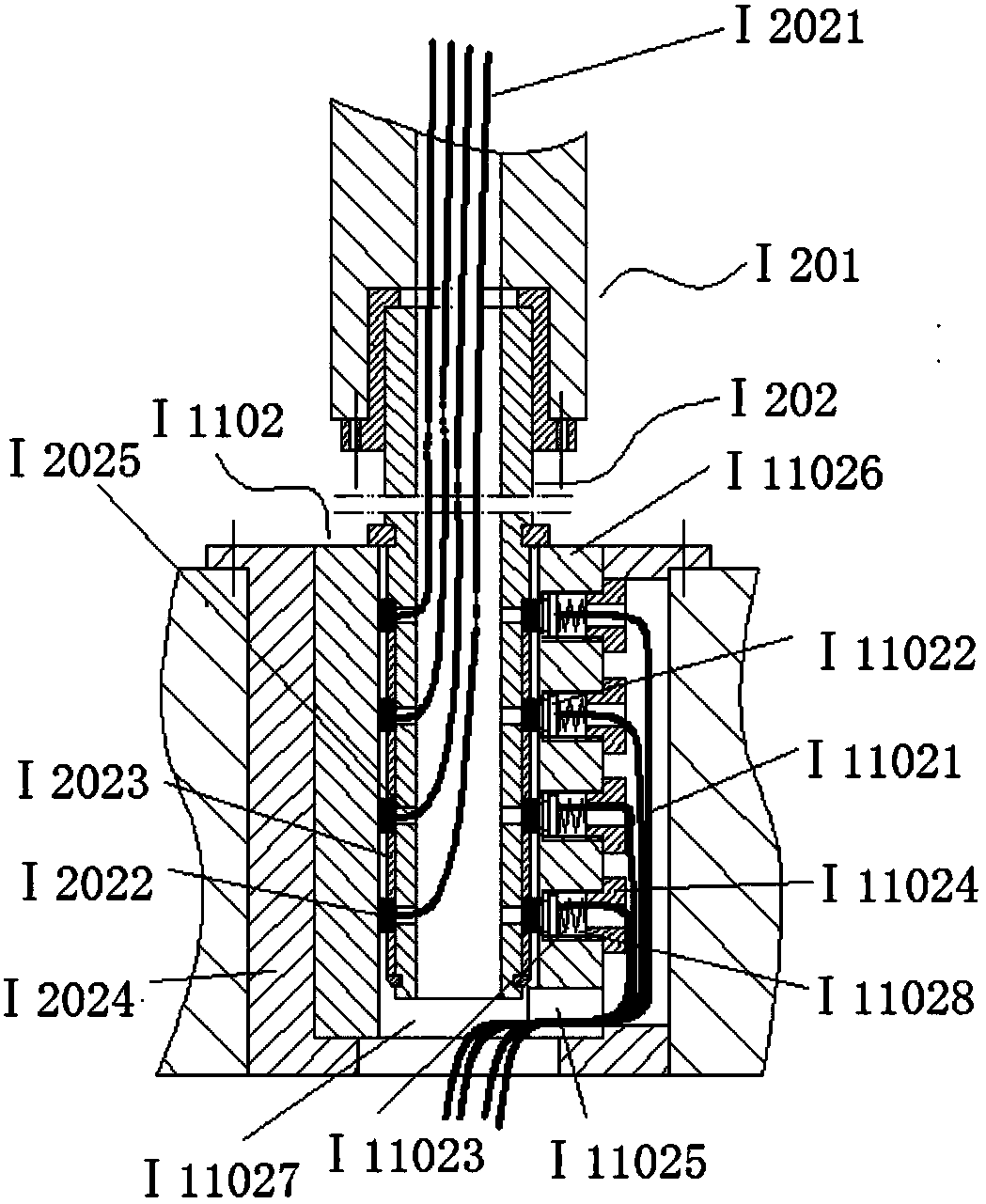

[0065] Such as figure 2As shown, the multi-core plug I202 includes a plug body I2024, a first electrical connection terminal I2022, an insulating ring I2023 and a first electrical connection wire I2021. The plug body I2024 is a hollow tube made of insulating material, and the ci...

Embodiment 2

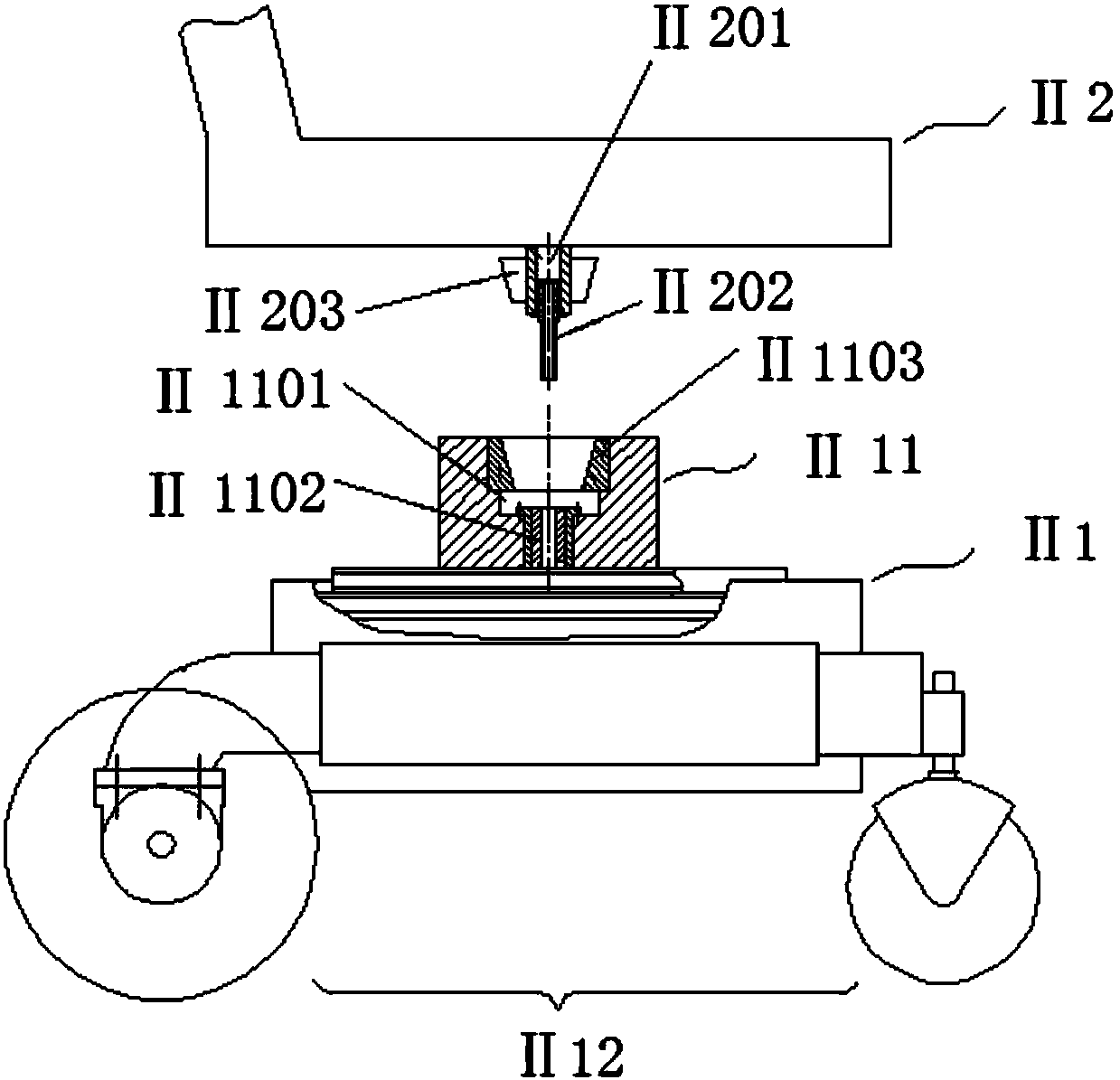

[0069] Such as image 3 As shown, the chassis device II1 of the present invention includes an electric traveling mechanism II12 and a base II11 arranged above the electric traveling mechanism II12. A support hole II1101 is provided on the upper surface of the base II11, a support sleeve II1103 is provided in the support hole II1101, and a multi-core socket II1102 is provided below the support hole II1101. Below the seat device II2 connected to the chassis device II1 in this embodiment, there is a rotating shaft II201, and a rotating body II203 is arranged on the rotating shaft II201. The rotating body II203 adopts a rotating body in a tapered roller bearing. The inner ring, the cage connected to the inner ring of the bearing and the tapered rollers supported on the cage are composed. The rotating body II203 is connected to the rotating shaft II201 through the inner ring of the bearing, and the supporting sleeve II1103 is the bearing outer ring of the rotating body, so that Th...

Embodiment 3

[0071] In order to better realize the rotation function of the upper seat device, the structure of the base II11 in Embodiment 2 is as follows: Figure 4 shown. The base II11 adopts the profile design, including the upper end plate II111 arranged along the length direction of the profile, the accommodation cavity arranged under the upper end plate II111, the positioning rib plate II117, the guide rib, the connecting shaft hole II115, the forming hole II1122 and the swing shaft hole II116 . The positioning rib plate II117 has at least a positioning plane parallel to the upper end plate II111, and divides the accommodation cavity into an upper accommodation cavity II112 and a lower accommodation cavity II113 distributed up and down, and two sets of guide ribs II114 are arranged on both sides of the lower accommodation cavity II113, separating There are two side accommodation chambers II 1131 and the middle chamber, and one of the side accommodation chambers II 1131 is used to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com