Ink jet printing spray head, ink jet amount measuring system and method and ink jet amount control method

An inkjet printing and measurement system technology, applied in printing, electrical components, electric solid devices, etc., can solve the problems of the difficulty of accurate measurement of ink droplet volume and the difficulty of accurate arrangement of multiple rows of nozzles, so as to improve the accuracy of inkjet printing and ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

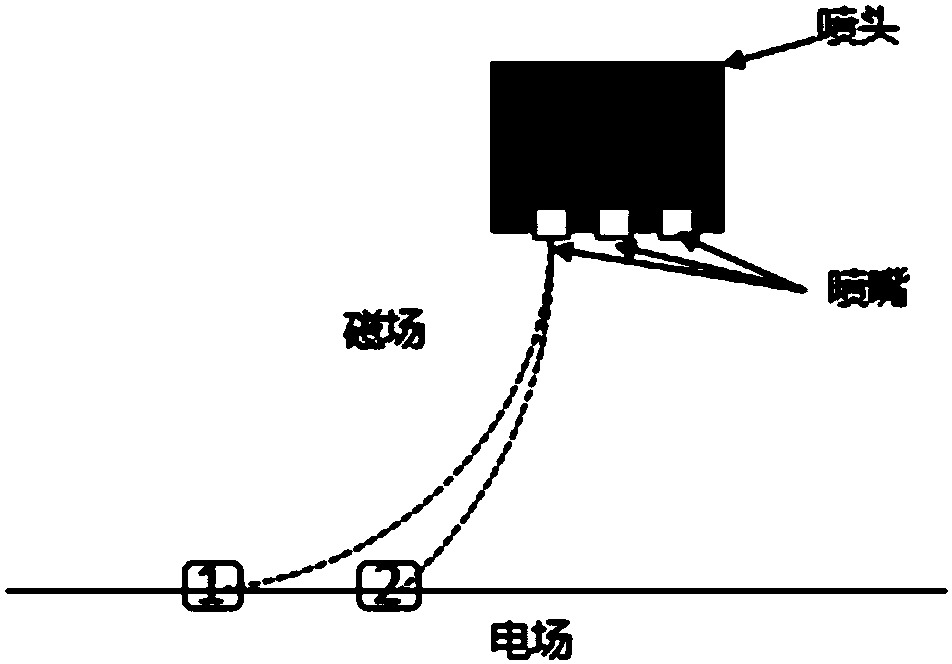

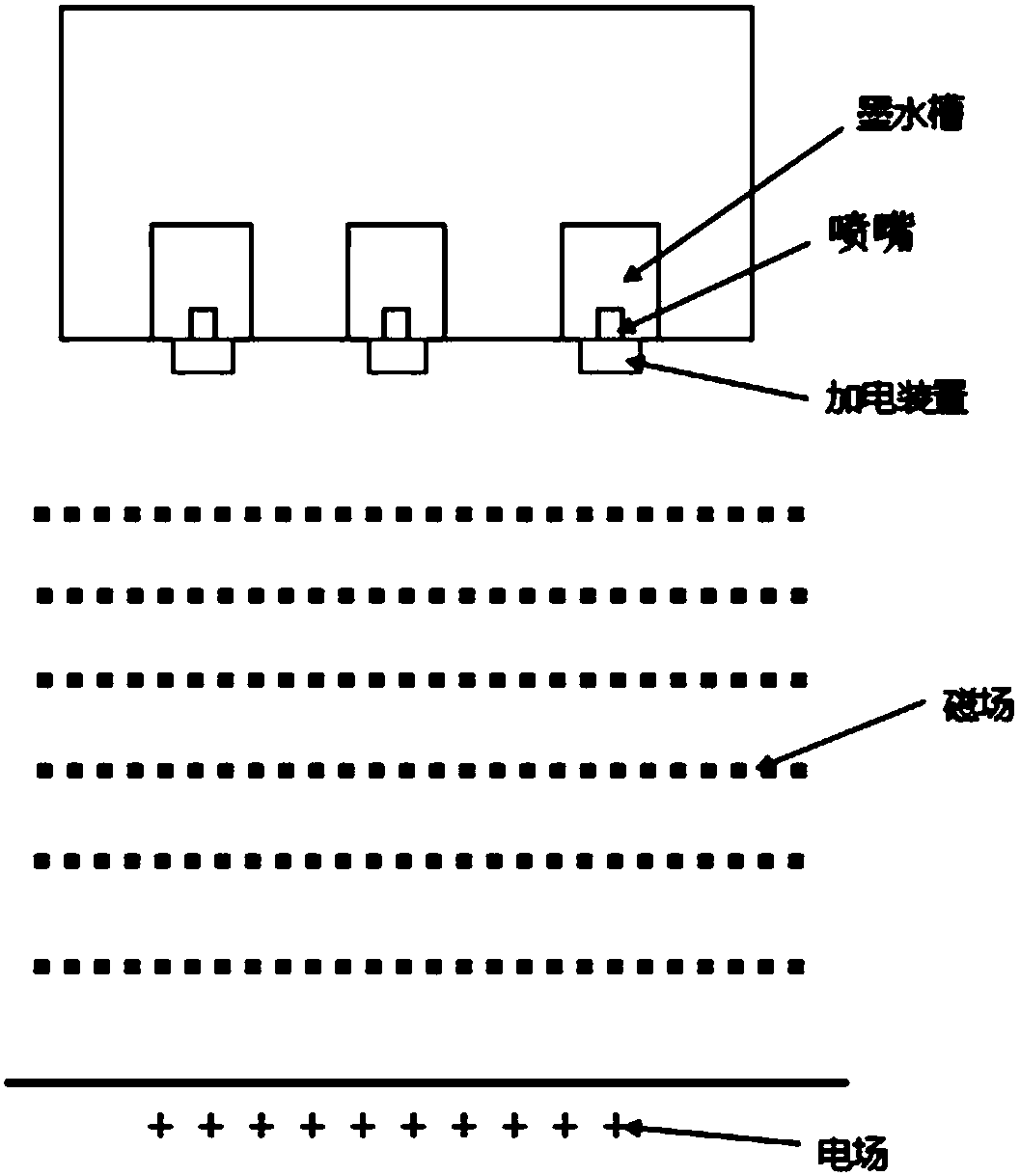

[0044] Such as figure 1 As shown, the nozzle of an inkjet printing device in the prior art is provided with a plurality of nozzles arranged in a multi-row matrix type. When printing, the nozzle is moved in parallel to print a certain film layer on the OLED display substrate. Realize printing pixels of the same specification with different nozzles. This nozzle solution facilitates the average amount of ink in each pixel, improves efficiency, and reduces the generation of random mura due to volume differences that exist bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com