Thermit welding die assembly for grinding nets

An aluminothermic welding and grounding grid technology, applied in aluminothermic welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of short service life (elimination after dozens of times, poor transportation convenience, low strength of graphite molds, etc. , to achieve the effect of improving the convenience of transportation, reducing the production cost and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and beneficial effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

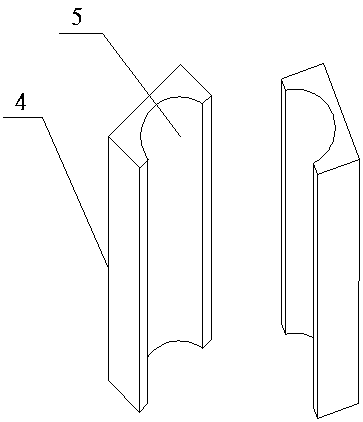

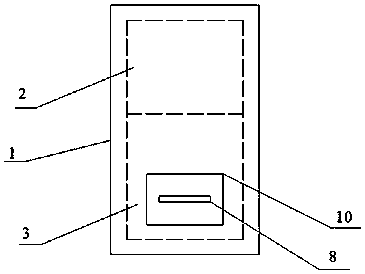

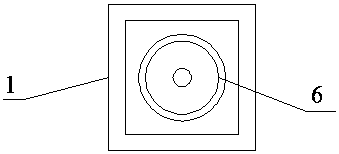

[0026] A mold assembly for aluminothermic welding of grounding grids, the specific embodiment of which is: a mold cover 1 made of cast iron, a cylindrical upper mold core 2 and a lower mold core processed by three-impregnated and four-baked graphite 3. The mold case 1 includes two half-moulds 4 of symmetrical structure. After the two half-moulds 4 are molded together, a cylindrical mold cavity 5 that can fix the upper mold core 2 and the lower mold core 3 is formed. The mold case 1 and the mold core Set separately, in the process of use, only need to select the upper mold core 2 and the lower mold core 3 of the corresponding specifications and sizes and put them into the mold sleeve 1 to carry out different forms of joint welding wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com