Organic amine absorption liquid for removing acid substances in airflow

A technology of acidic substances and organic amines, applied in the field of absorbing liquid based on cyclic group organic amines, can solve the problems of irreversible reaction, solvent loss, poor removal effect of organic sulfur, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

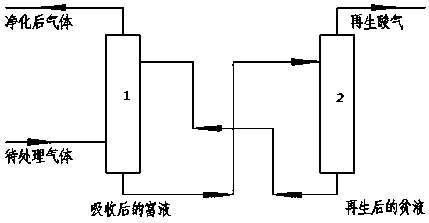

Image

Examples

Embodiment 1

[0021] Composition of raw material gas to be treated: hydrogen sulfide ~7.5% (mol), carbon dioxide ~6% (mol), methyl mercaptan ~350mg / Nm 3 , carbonyl sulfide~500mg / Nm 3 .

[0022] The composition of the absorption liquid: 30% (wt) of diisopropanolamine, 5% (wt) of 4,5-dihydroxyimidazole, 15% (wt) of N-acetylimidazole, and the circulation volume of the absorption liquid is 5L / h.

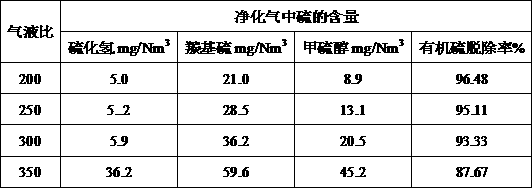

[0023] The absorption pressure in this implementation case is 2.8MPa, and the composition of the purified gas after treatment is as follows:

[0024]

Embodiment 2

[0026] Composition of raw material gas to be treated: hydrogen sulfide ~7.5% (mol), carbon dioxide ~6% (mol), methyl mercaptan ~350mg / Nm 3 , carbonyl sulfide~500mg / Nm 3 .

[0027] The composition of the absorption liquid: 30% (wt) N-methyldiethanolamine, 5% (wt) 1-methyl-2-ethylimidazole, 15% (wt) N-acetylimidazole, the circulation volume of the absorption liquid is 5L / h.

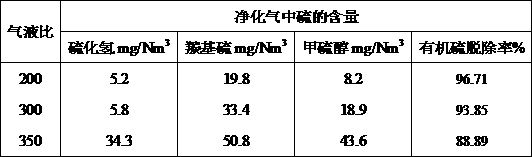

[0028] The absorption pressure in this implementation case is 3.2MPa, and the composition of the purified gas after treatment is as follows:

[0029]

Embodiment 3

[0031] Composition of raw material gas to be treated: hydrogen sulfide ~7.5% (mol), carbon dioxide ~6% (mol), methyl mercaptan ~350mg / Nm 3 , carbonyl sulfide~500mg / Nm 3 .

[0032] The composition of the absorption liquid: 40% (wt) of N-methyldiethanolamine, 5% (wt) of 2-methyl-5-ethylpyridine, 15% (wt) of N-methylpyrrolidone, the circulation volume of the absorption liquid is 5L / h.

[0033] The absorption pressure in this implementation case is 6.0MPa, and the composition of the purified gas after treatment is as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com