Stretchable supercapacitor with stainless steel spring adopted as base

A supercapacitor and stainless steel technology, applied in the direction of hybrid capacitor electrodes, hybrid capacitor separators, hybrid capacitor collectors, etc., can solve the problem of loss of stretchability and achieve good stretchability and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

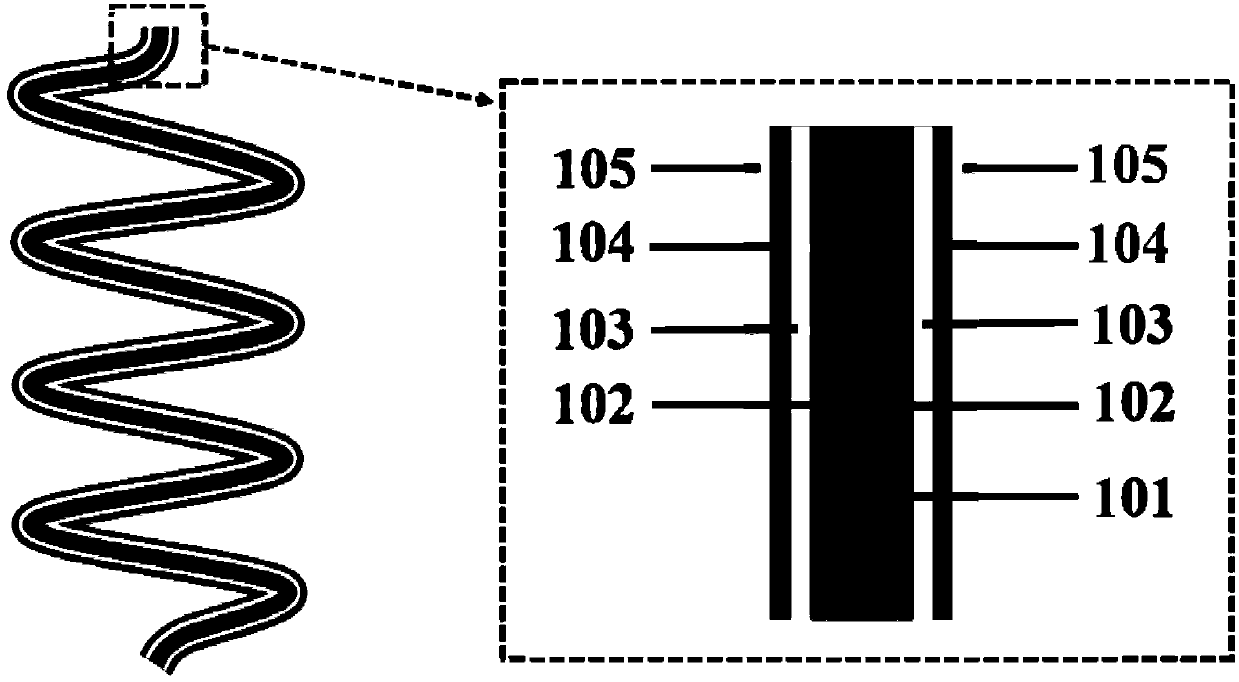

[0039] see figure 1 , the shape of the stretchable supercapacitor device is similar to that of a spring. It can be seen from the cross-sectional view that it has a coaxial concentric circle structure: the innermost layer is a stainless steel spring 101, and the inner layer electrode material 102 is deposited on the surface of the spring substrate through in-situ growth. The inner electrode is covered with a gel electrolyte 103, which plays the role of isolating electron transmission and conducting ions. The outer electrode 104 is wrapped around the electrolyte 103, and the entire device is packaged with a flexible insulating polymer material 105. The device structure design is explained below with specific examples:

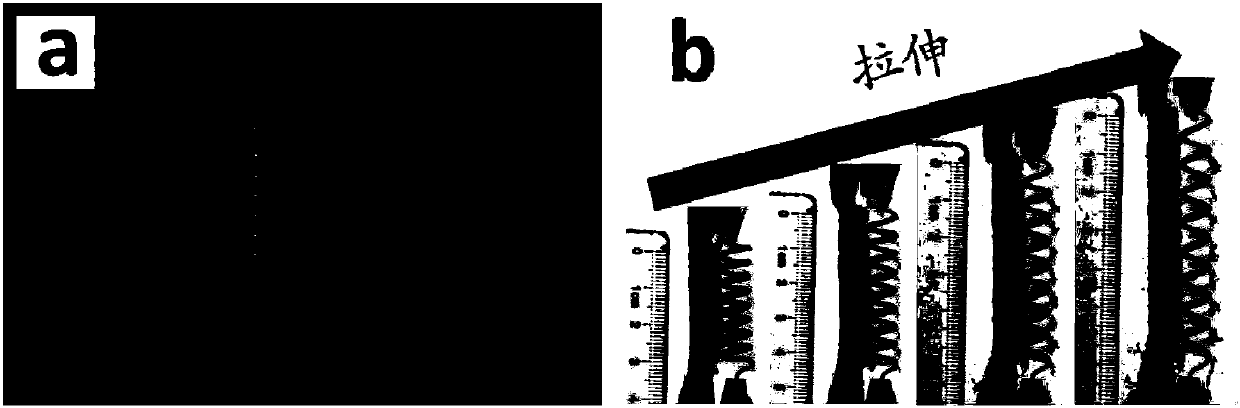

[0040] Such as figure 2 As shown, this example uses a stainless steel tension spring with a model size of 30×8×0.8mm and a material of 316L as a stretchable substrate, and through Mg powder and CO 2 at 800 o The redox reaction under C deposited the carbon mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com