MXene-base composite fiber super capacitor

A technology of supercapacitors and composite fibers, applied in hybrid capacitor electrodes, hybrid capacitor electrolytes, capacitors, etc., can solve the problems of limiting MXene, weak self-supporting ability of MXene sheets, and no spinning technology development, and achieve good conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation of MXene / graphene composite fiber

Embodiment 1-1

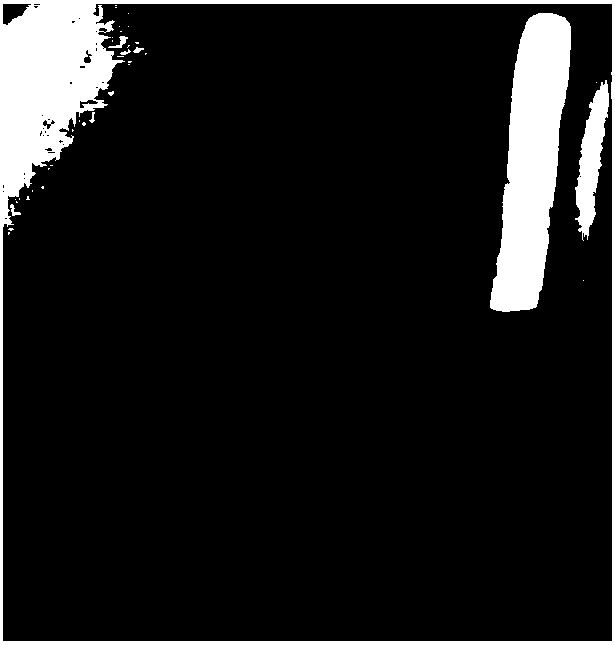

[0042] (1) Xiang Rufigure 1 The two-dimensional layered Ti shown 3 C 2 A single-layer graphene oxide is added to the dispersion, wherein the quality of the single-layer graphene oxide is 5% of the total mass of the solute;

[0043] (2) Extrude the MXene-graphene oxide mixed solution at an extrusion speed of 100mL / h through a spinning head capillary with a pore diameter of 250 μm, and then enter a coagulation bath of 5wt% calcium chloride water / isopropanol solution to obtain MXene / graphene oxide composite fibers with a diameter of about 25 microns;

[0044] (3) Place the MXene primary fiber obtained in step (2) in hydroiodic acid and acetic acid reducing agent, wash and dry at 90° C. for 12 h to obtain the MXene / reduced graphene oxide composite fiber.

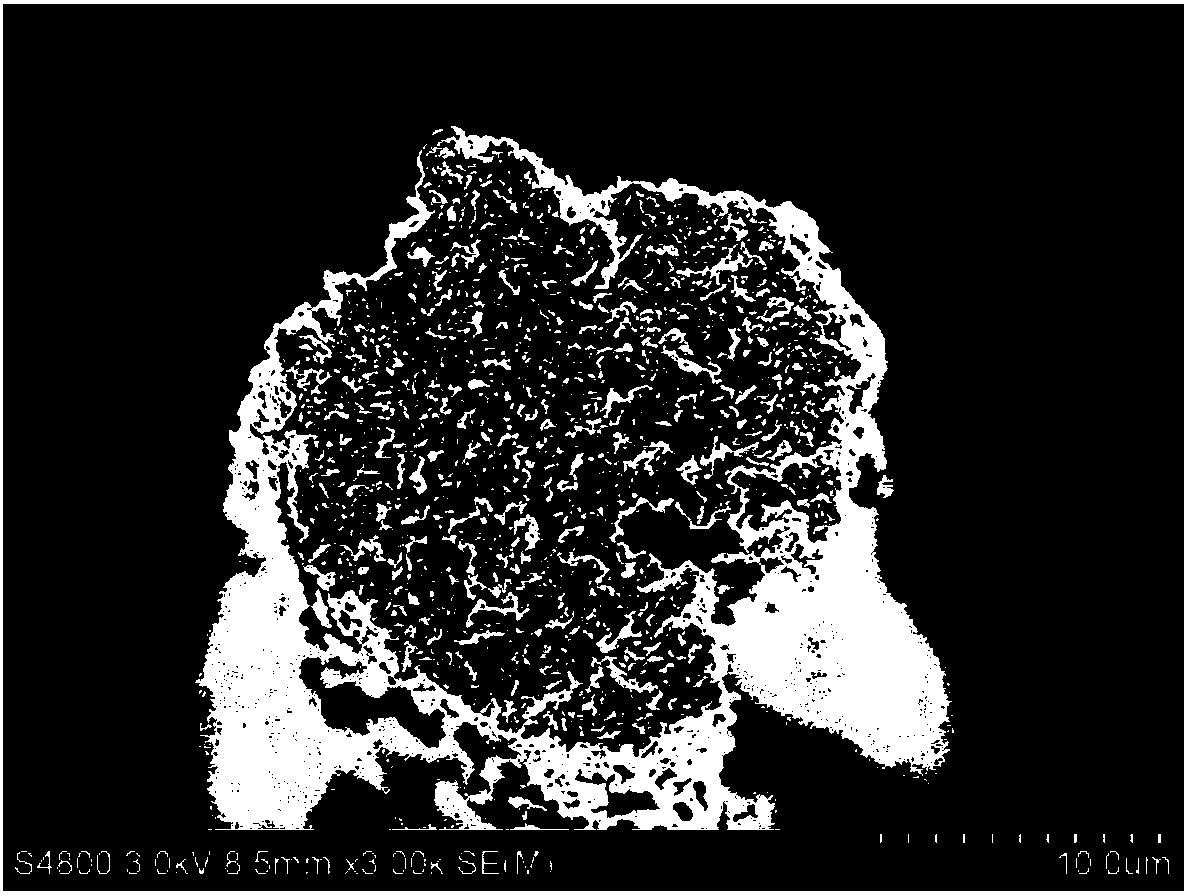

[0045] Through the above steps, MXene fibers are obtained, such as figure 2 Shown; The cross-sectional scanning electron microscope picture of the obtained MXene fiber is shown in image 3 Shown; The specific properties of ...

Embodiment 1-2

[0047] (1) Xiang Ru figure 1 The two-dimensional layered Ti shown 3 C 2 A single-layer graphene oxide is added to the dispersion, wherein the mass of the single-layer graphene oxide is 50% of the total mass of the solute;

[0048] (2) Extrude the MXene-graphene oxide mixed solution at an extrusion speed of 60mL / h through a spinning head capillary with an aperture of 250 μm, and then enter a coagulation bath of 5wt% calcium chloride water / isopropanol solution to obtain MXene / graphene oxide composite fibers with a diameter of about 19 microns;

[0049] (3) The MXene primary fibers were placed in hydroiodic acid and acetic acid reducing agents, washed and dried at 90°C for 12 hours to obtain MXene / reduced graphene oxide composite fibers.

[0050] Through the above steps, MXene fibers are obtained; MXene rich in Ti elements in the obtained MXene fibers is evenly distributed in the MXene fibers, and the distribution diagram of the surface and internal Ti elements is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com