Chaos-based early-stage single point of failure detection and classification method for mechanical part

A technology of mechanical parts and single point of failure, applied in computer parts, special data processing applications, instruments, etc., can solve the professional requirements of manual adjustment, difficult to achieve early forecast, unable to automatically detect and other problems, to increase engineering applications performance, improved versatility and accuracy, high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

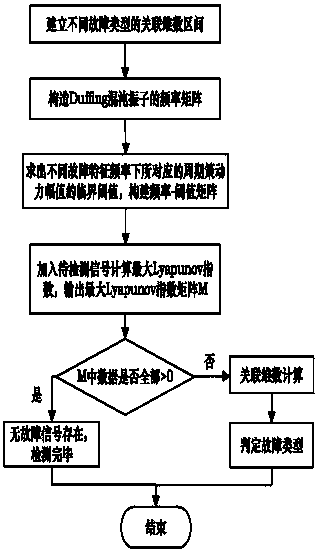

Method used

Image

Examples

Embodiment

[0102] This example uses the rolling bearing fault signal provided by the Bearing Data Center of Washington Catholic University for verification. The sample signals under the four states of normal, inner ring fault, outer ring fault and rolling element fault are respectively used to detect the fault detection and classification method of the present invention based on the combination of Lyapunov exponent and correlation dimension of early single point faults of mechanical parts Verification, the specific steps are as follows:

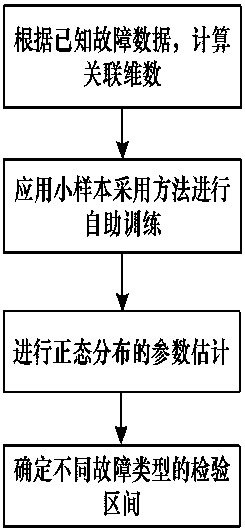

[0103] Step 1: Establish correlation dimension intervals of different fault types.

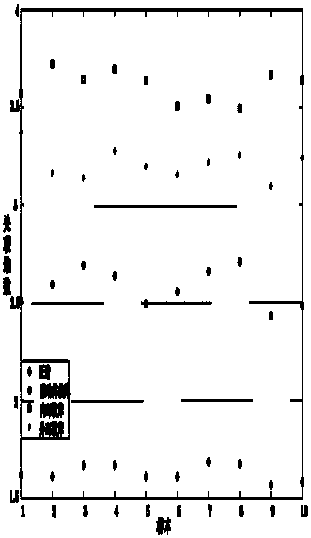

[0104] The correlation dimension is calculated according to the existing actual fault data of rolling bearings, as shown in Table 1.

[0105] Table 1 Correlation dimension of vibration signals of rolling bearings in different states

[0106] For the existing sample fault signals in different states of mechanical parts, calculate the corresponding correlation dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com