Characterization method of material fatigue, creep, and fatigue-creep interaction service life

A creep and fatigue technology, applied in the field of measurement and testing, can solve problems such as not easy to obtain suitable material parameters, imperfect basic theory of support methods, cumbersome parameter optimization and fitting procedures, etc., to speed up material development and engineering application and structure The process of integrity assessment, significant scientific research value and engineering application significance, and the effect of good application prospects

Active Publication Date: 2018-02-09

AVIC BEIJING INST OF AERONAUTICAL MATERIALS

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Some life prediction models have a certain physical mechanism and have formed a relatively mature theoretical system, but their equations are complex, with many material parameters or even values across scales. The parameter optimization and fitting procedures are cumbersome, and it is not easy to obtain suitable material parameters. As a result, the prediction accuracy will be greatly reduced, and it is not suitable for engineering applications

In addition, some life prediction models are based on the macroscopic phenomenological method, the equation form is simple and the material parameters are easy to obtain, but they lack clear physical meaning, and the basic theory supporting the method research is not perfect, so it is difficult to popularize and apply

So far, researchers at home and abroad have not proposed a reliable, concise and physically meaningful life prediction method that can simultaneously characterize and predict the low-cycle fatigue, creep and fatigue-creep interaction life of materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0034] Example: Low cycle fatigue, creep and fatigue-creep interaction unified life characterization and prediction of TiAl alloy at 750°C and 800°C, the steps of the method are:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

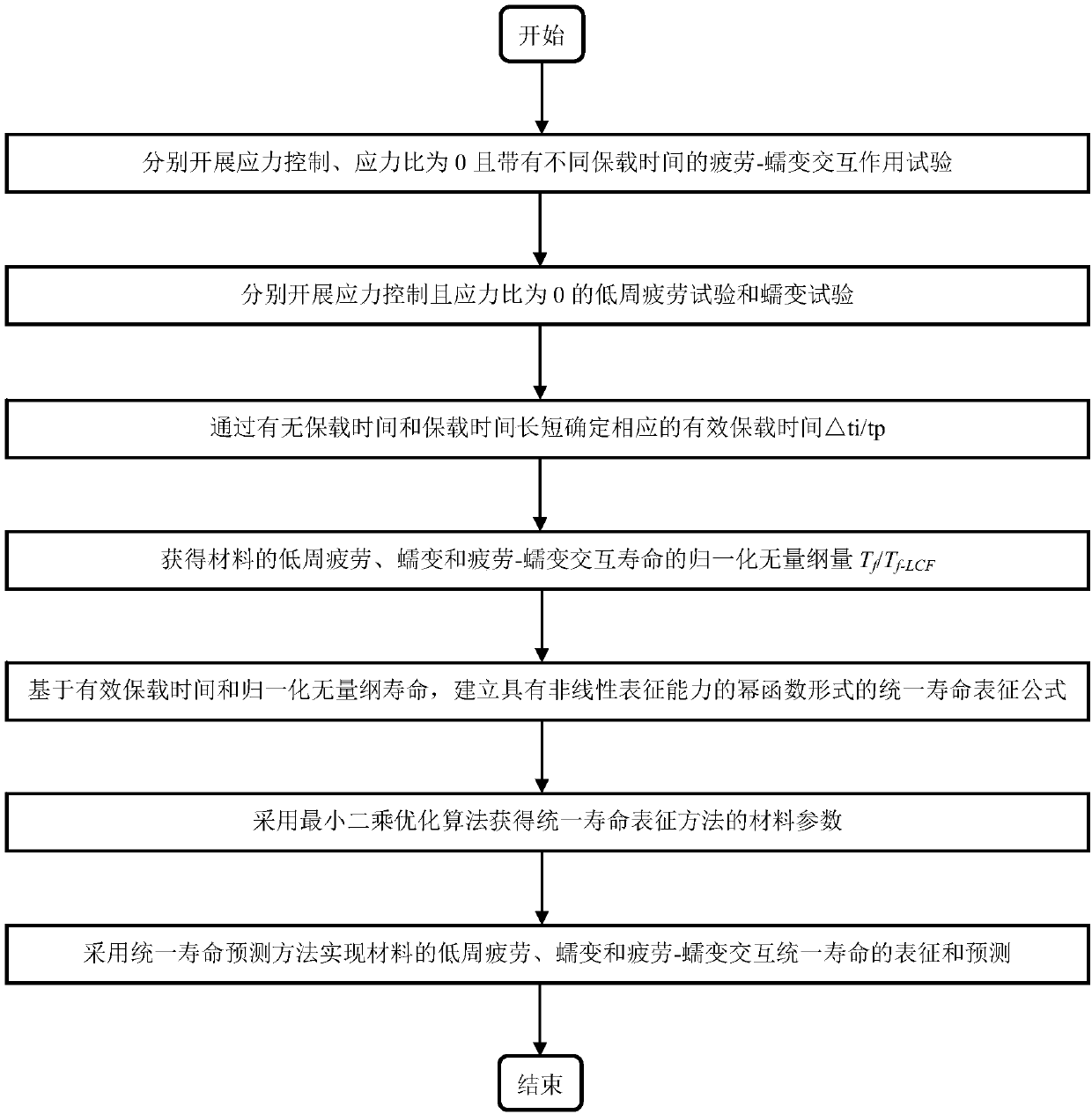

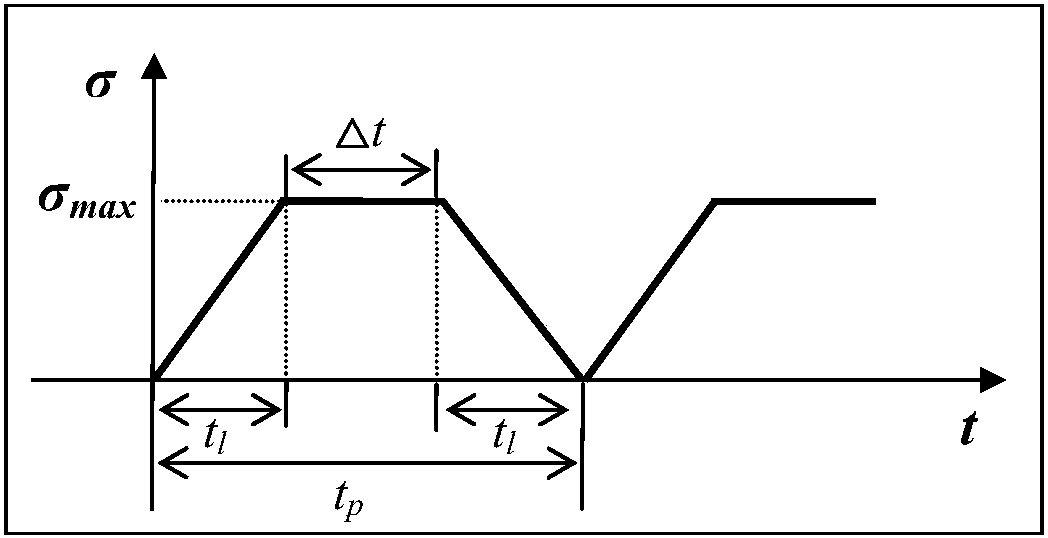

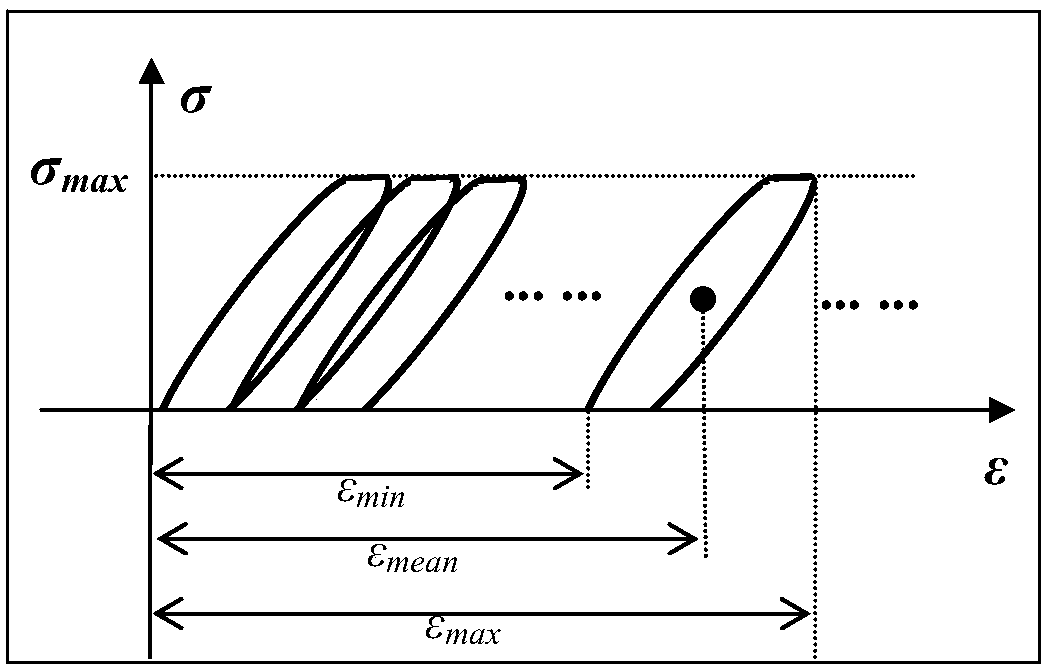

The invention discloses a characterization method of material fatigue, creep, and fatigue-creep interaction service life, and belongs to the field of service life prediction of aero-engine critical materials. The characterization method is used for solving service life characterization and prediction problems of materials under low cycle fatigue, creep, and fatigue-creep interaction conditions. According to the principles, a power function form service life prediction method non-linear behavior characterization capacity is established via fatigue-creep interaction, low cycle fatigue, and creeptests of materials at different holding time, and obtaining of effective holding time and normalization dimensionless service life via normalization calculation method. The characterization method iscapable of realizing accurate characterization of service life of materials under low cycle fatigue and fatigue-creep interaction conditions, and especially, consideration and accurate prediction ofcreep service life can be realized. The advantages of the characterization method are that consideration of both physical mechanisms and model implementation convenience is realized, and material lowcycle fatigue, creep, and fatigue-creep interaction service life characterization and prediction problems are solved effectively.

Description

technical field [0001] The invention is a characterization method for the fatigue, creep and fatigue-creep interactive unified life of a material. [0002] The invention relates to life prediction of aero-engine structural materials and belongs to the technical field of measurement and testing. Background technique [0003] In important national industrial fields such as energy and power, petrochemical, nuclear power and aerospace, many high-temperature structural materials with excellent comprehensive mechanical properties are widely used in the processing and manufacturing of high-temperature components in key parts of industrial products. During service, these high-temperature components often suffer from fatigue damage due to repeated start-stop transient load cycles, and some high-temperature components have to work at a certain stable temperature for a long time, resulting in time-related creep damage , and even some high-temperature components have to work under fati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/08

CPCG01N3/08G01N2203/0017G01N2203/0073

Inventor 董成利焦泽辉于慧臣

Owner AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com