Unit sleeve tooth telescopic device

A technology of telescopic devices and sets of teeth, which is applied to bridge parts, bridges, buildings, etc., can solve problems such as component fatigue, complex structure, wear and tear, etc., to achieve the change of large occupied space, improved safety and durability, and displacement The effect of empowerment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

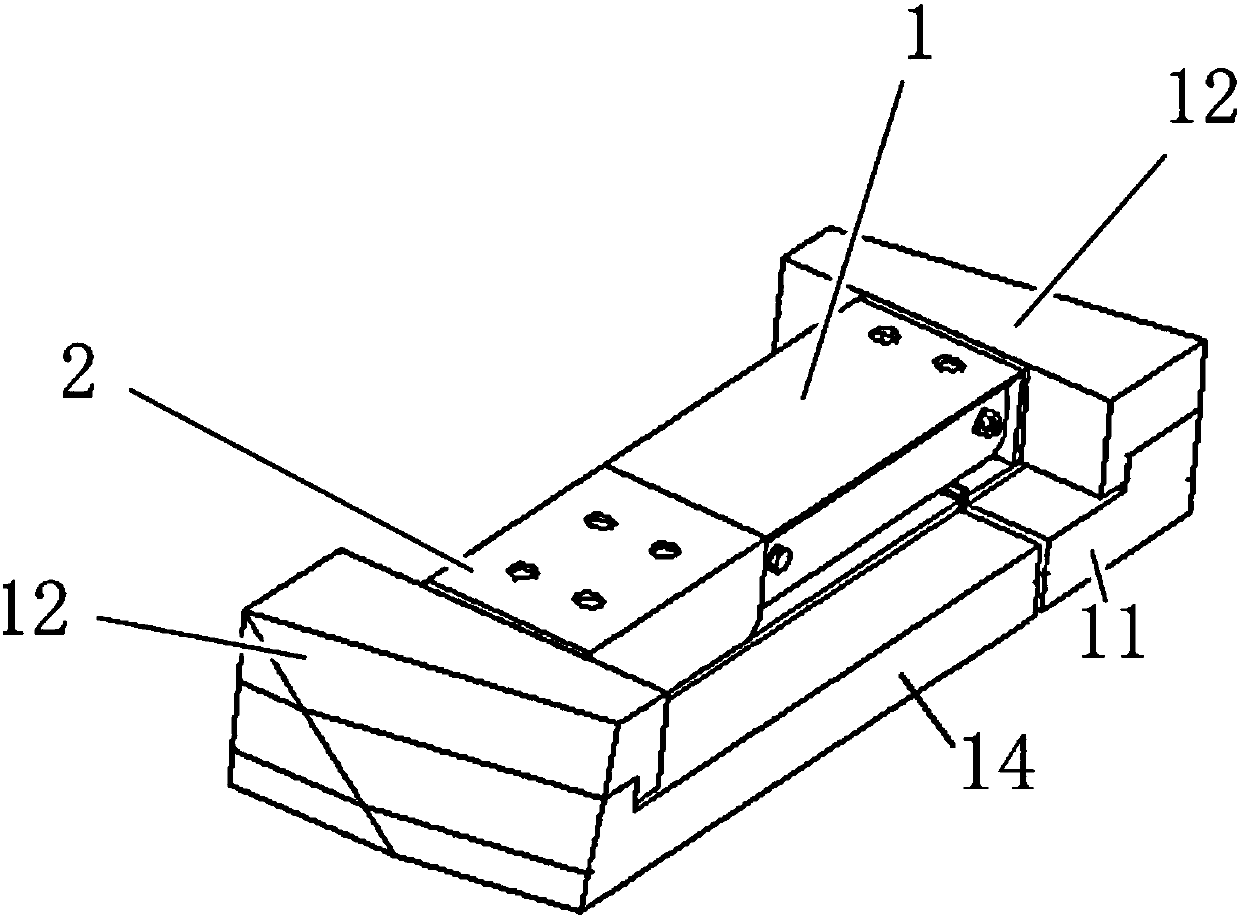

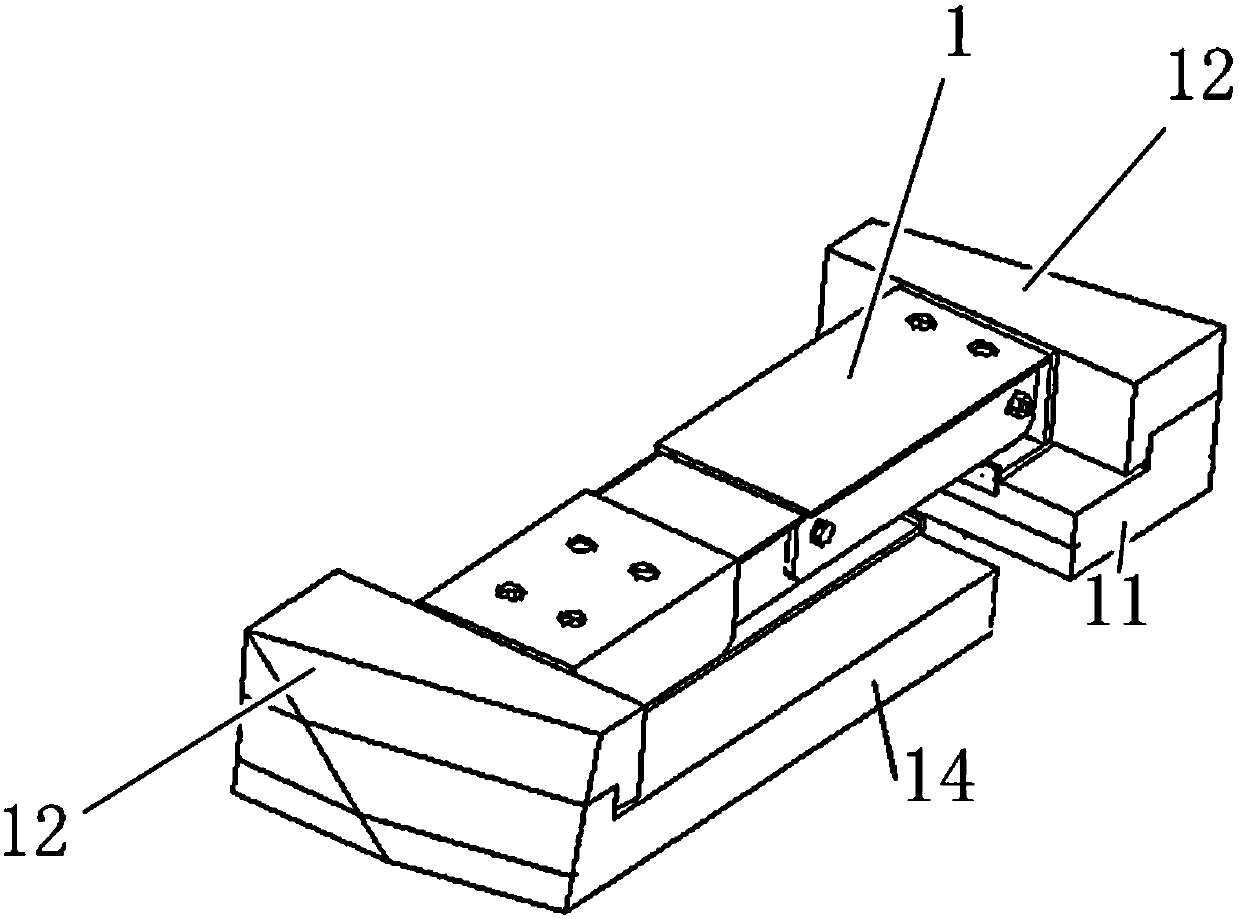

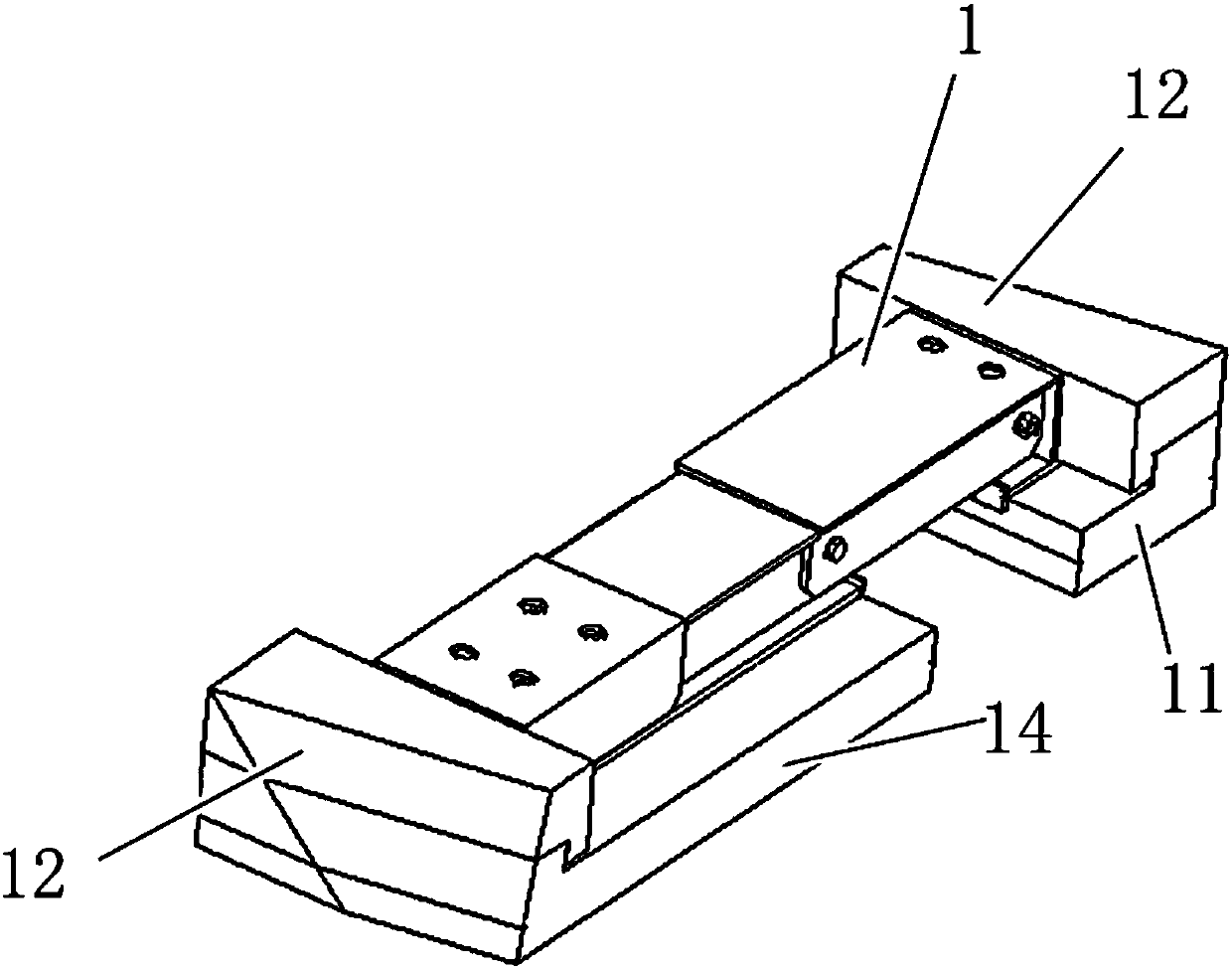

[0028] A kind of unit sleeve gear telescopic device, such as Figure 1-4 As shown, it is arranged between the first beam end 11 and the second beam end 14. The unit set tooth telescopic device includes a unit sliding member 1 and a unit set tooth member 2. The unit sliding member 1 is set in the unit set tooth member 2. The unit gear member 2 guides and limits, forming a shallow telescopic device with stable functions;

[0029] The unit sliding member 1 includes a slot-spanning slot 3 and a sliding slot 7, the sliding slot 7 is arranged on the second beam end 14, a fixed base 5 is provided on the first beam end 11, and one end of the slot-spanning slot 3 is connected by a rear bolt hinge 4 On the fixed base 5 on the first beam end 11, the fixed base 5 is fixed on the first beam end 11 by anchor bolts 10, and the other end of the cross slot 3 is connected to the second beam end 14 by the front bolt hinge 6 On the sliding groove 7, a double-hinge spanning structure that can ada...

Embodiment 2

[0036] Such as Figure 1-3 As shown, a unit set tooth telescopic device with a stretching amount of 240 mm includes a unit sliding member 1 and a unit set tooth member 2 . The unit sliding member 1 is fitted in the unit gear member 2 after crossing the seam, and is guided and limited by the unit gear member 2 to form a shallow telescopic device with stable functions.

[0037] Such as Figure 4 , The unit sliding member 1 and the unit set gear member 2 adopt groove-shaped welded members with high strength and rigidity and low overall height. Component materials are Q345C steel plates with a thickness of 6mm and 8mm.

[0038] Such as Figure 4 The unit sliding member 1 connects one end of the cross slot 3 to the fixed base 5 on the first beam end 11 with the M24 rear bolt hinge 4, and the other end is connected to the second beam end 14 with the M24 front bolt hinge 6 On the sliding groove 7 on the top, a kind of double-hinge spanning structure that can adapt to the lateral,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com