High-precision automatic conveying mechanism for metal plates

A technology for automatic conveying of sheet metal, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as poor effect, hidden safety hazards, easy to hurt hands, etc., to achieve reduced bumps, high precision, accurate conveying position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

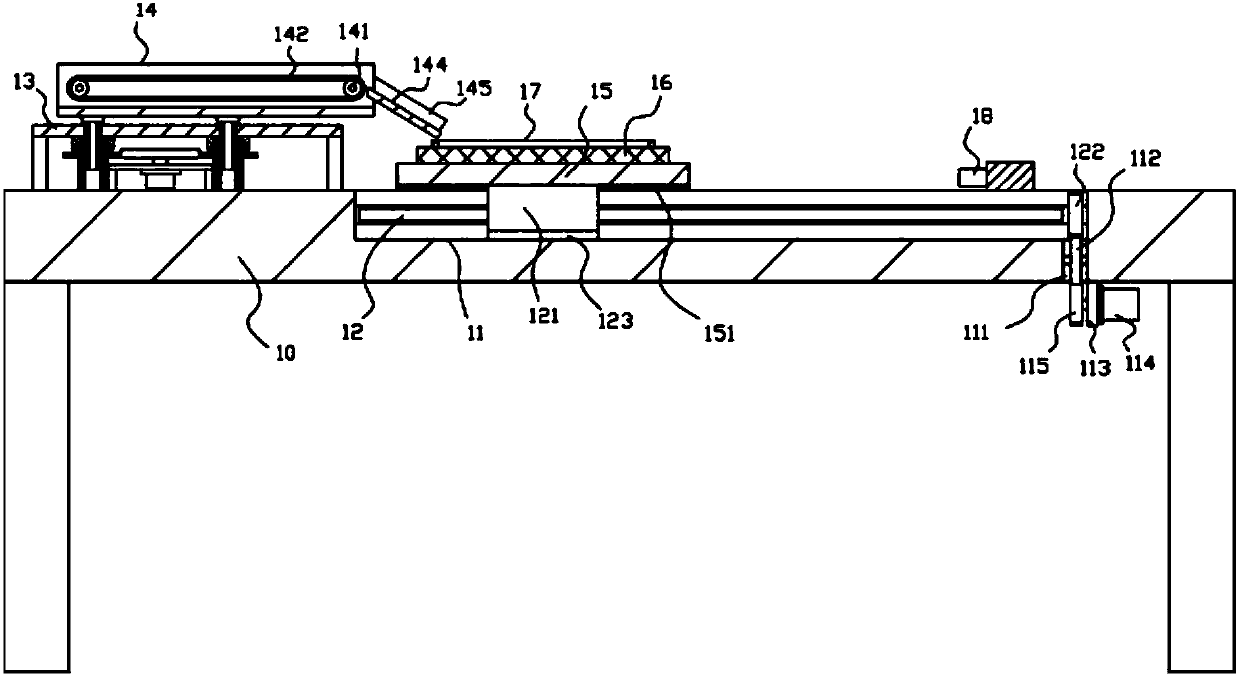

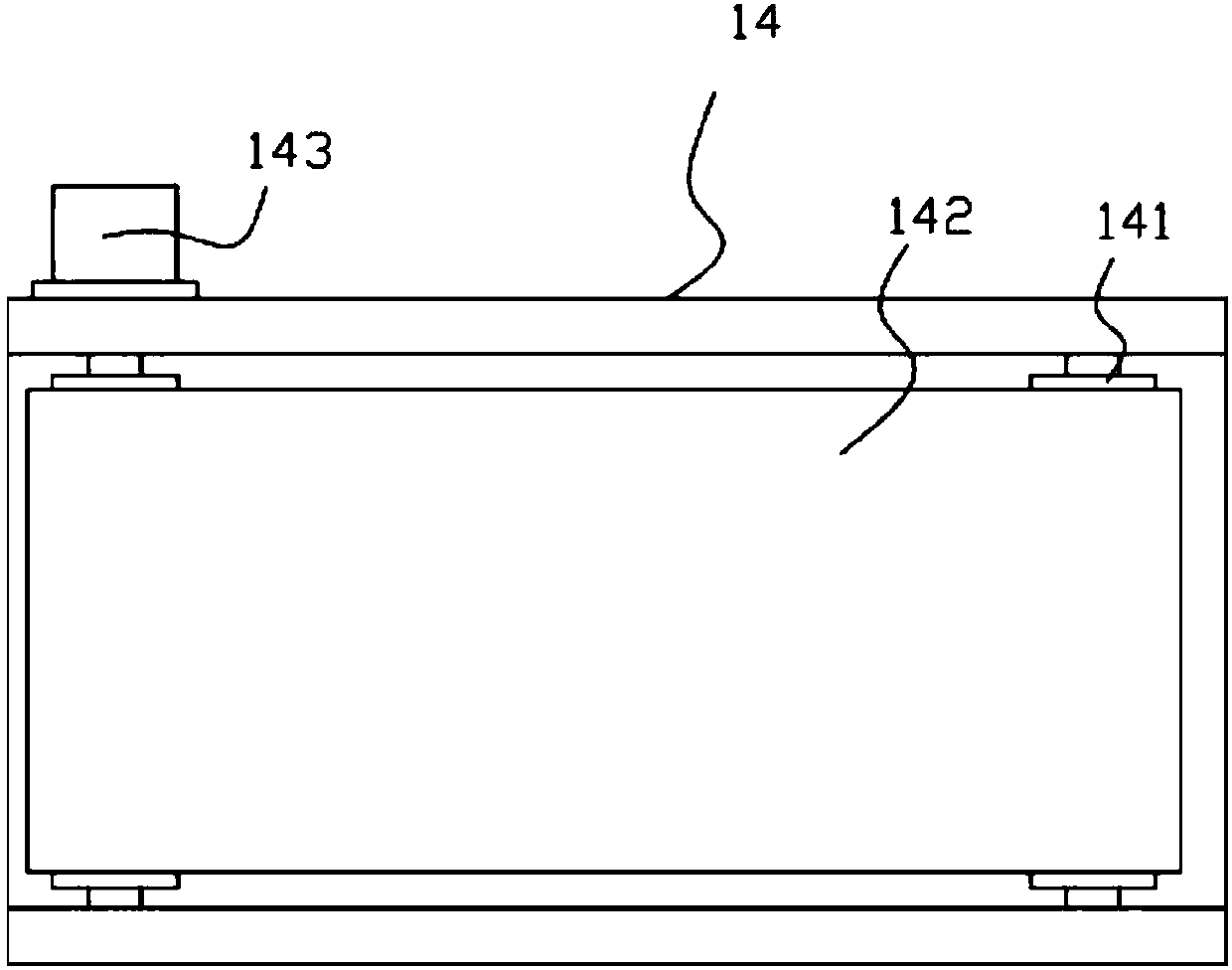

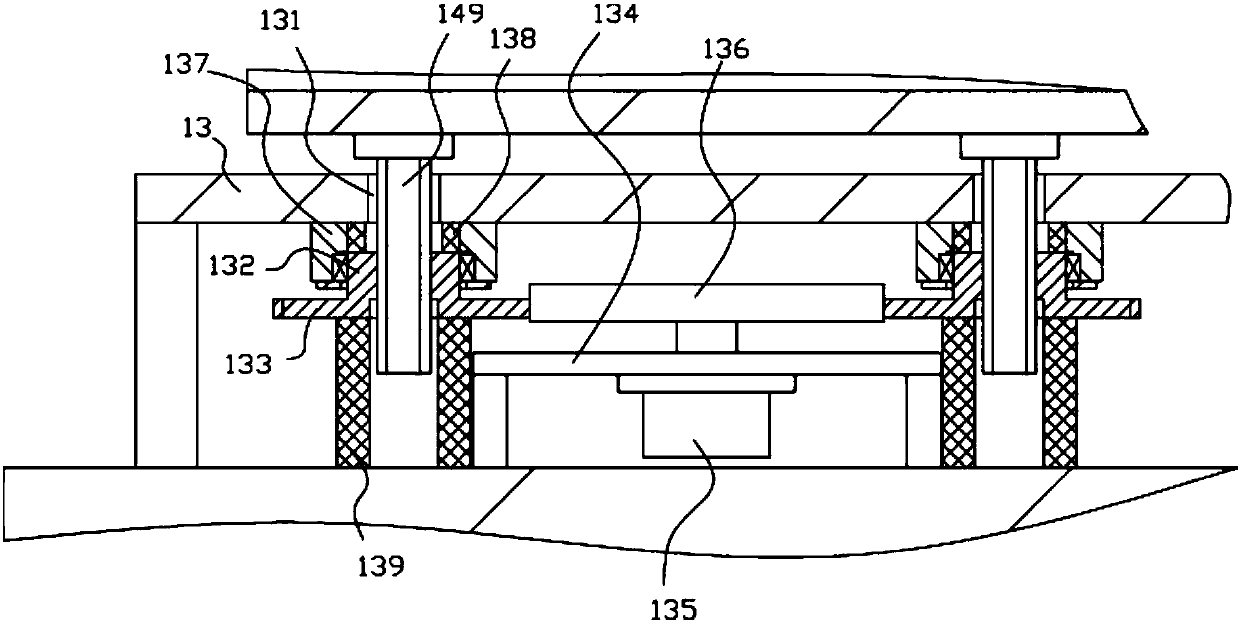

[0019] Example: see Figure 1 to Figure 3 As shown, a high-precision sheet metal automatic conveying mechanism includes a frame 10, the middle part of the top plate of the frame 10 has a mounting groove 11, and a horizontal screw 12 is inserted in the mounting groove 11, and the horizontal screw 12 The two ends are hinged on the left and right inner walls of the mounting groove 11, the moving block 121 is screwed into the transverse screw 12, the right end of the transverse screw 12 is fixed with the main transmission gear 122, and the bottom surface of the right end of the mounting groove 11 has an installation cavity 111, the intermediate transmission gear 112 is inserted into the installation cavity 111, the two ends of the middle rotating shaft of the intermediate transmission gear 112 are hinged on the two inner side walls of the installation cavity 111, the intermediate transmission gear 112 meshes with the main transmission gear 122, The bottom surface of the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com