System and method for laying underground cables or pipelines near the surface in the ground

A technology for underground pipelines and underground cables, applied in cable laying equipment, drilling equipment and methods, cable installation in underground pipelines, etc., can solve the problem of undesired flushing liquid, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

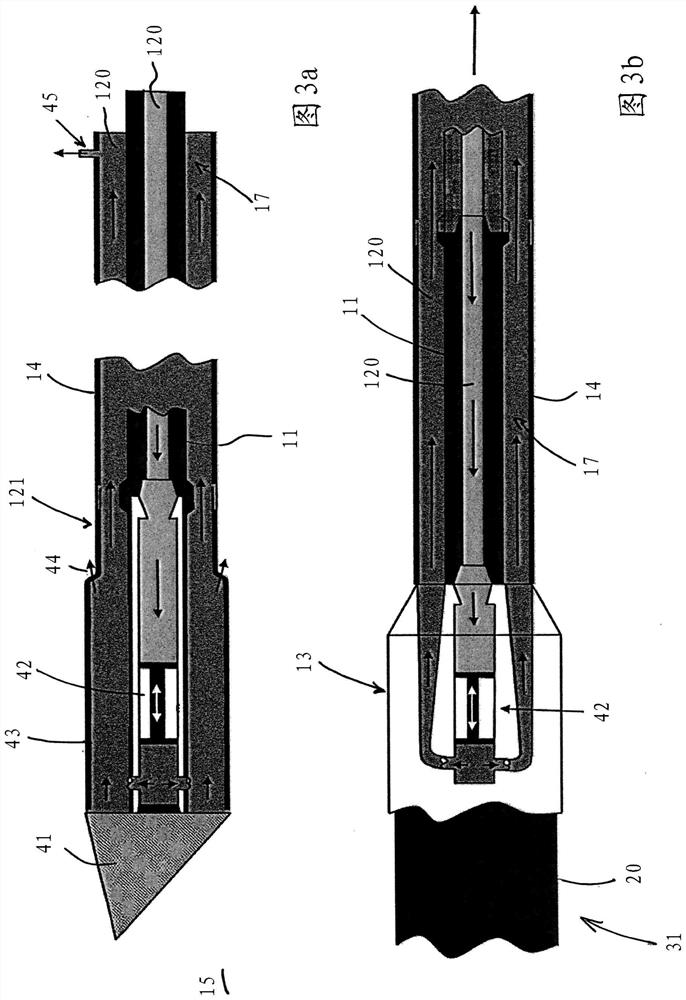

[0033] The HDD drilling device 10 is installed at the starting point 100 ( figure 1 , figure 2) and connected with the jacking head 12 via the drill pipe 11. Furthermore, a casing 14 surrounding the drill pipe 11 is provided. With the torque and propulsion provided by the drilling device 10 , the jacking head 12 is pushed along the direction of the predetermined path 101 to the target point 110 .

[0034] exist figure 1 A hammer drill 15 is shown and used as the jacking head 12 in FIG. The advancing movement takes place here via the sleeve 14 . The drill rod 11 is used for supplying flushing fluid for driving the drill hammer 15 and for rotating the drill hammer 15 , for example for control.

[0035] exist figure 2 A displacement screw 16 is provided as the jacking head 12 in the middle. The advancing movement takes place here via the sleeve 14 . The drill rod 11 is used to rotate the displacement screw 16 . The displacement screw can be controlled by supplying flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com