A stripping method of photoresist with nanoscale size on semiconductor

A semiconductor and photoresist technology, which is applied in the field of nanoscale photoresist stripping on semiconductors, can solve problems such as unexposed photoresist residues, and achieve high-quality stripping, cost reduction, and small damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

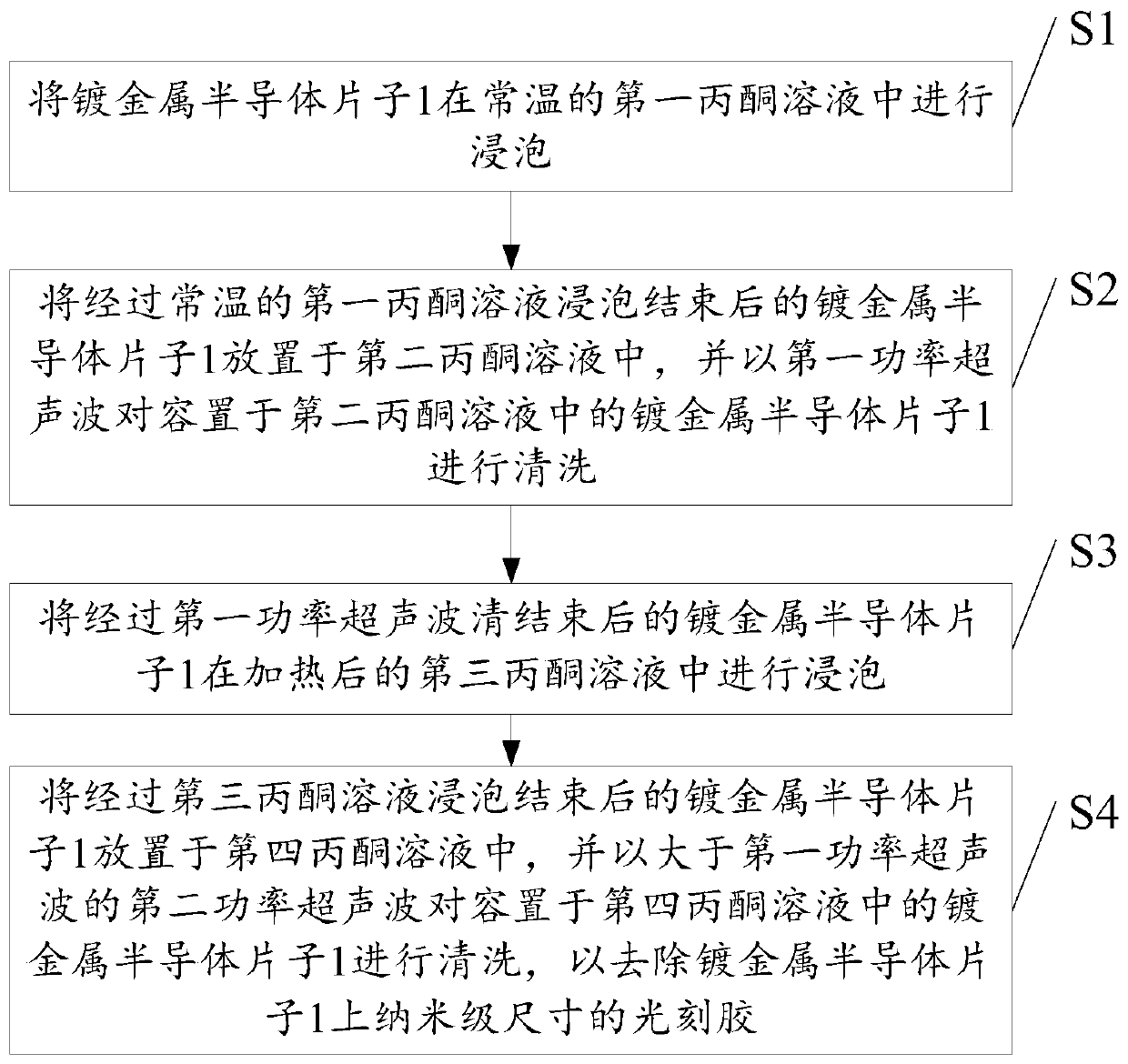

[0038] The embodiment of the present invention solves the technical problem of unexposed photoresist residue in the nanoscale structure by providing a stripping method of nanoscale photoresist on the semiconductor. The general idea is as follows:

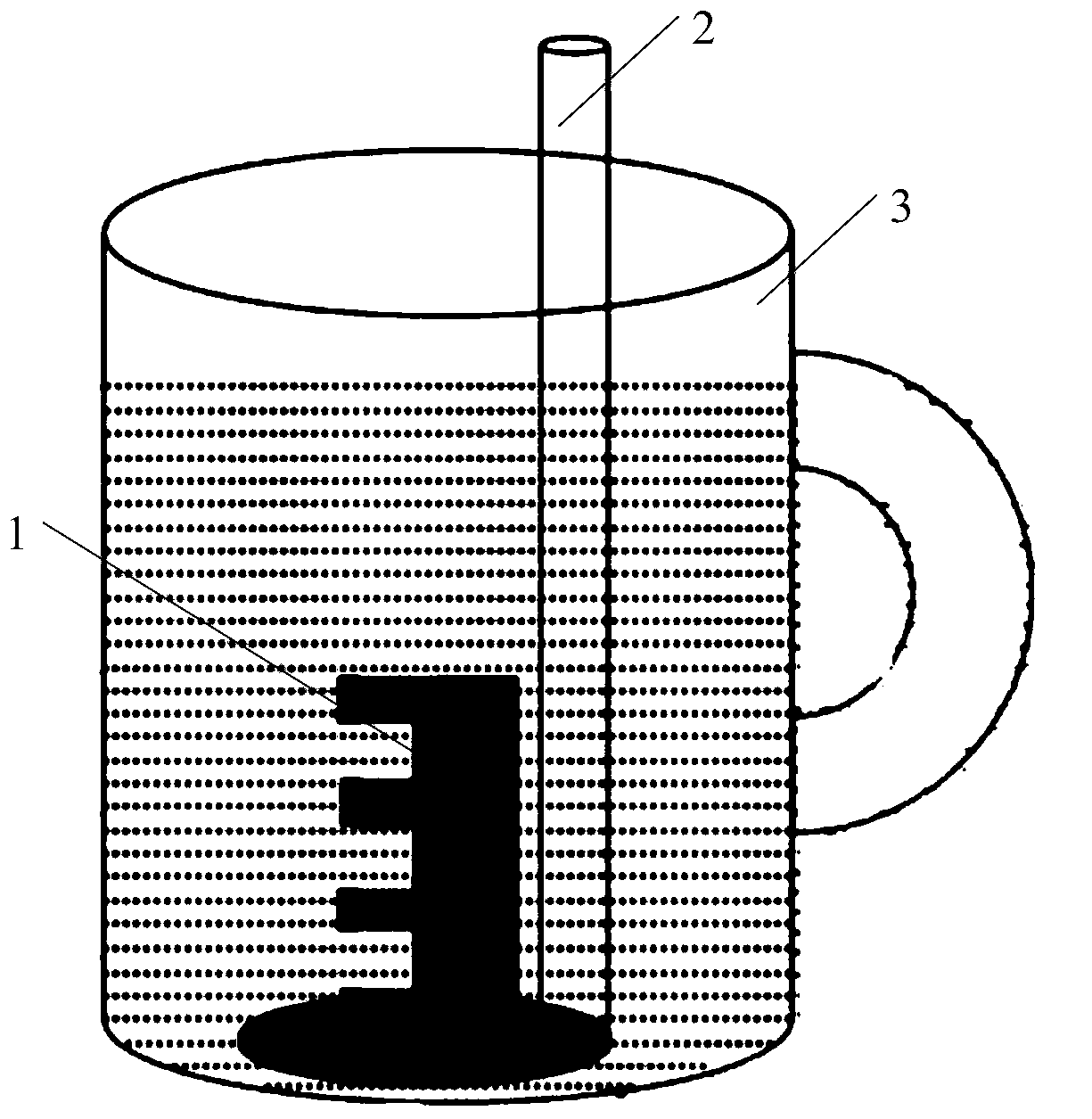

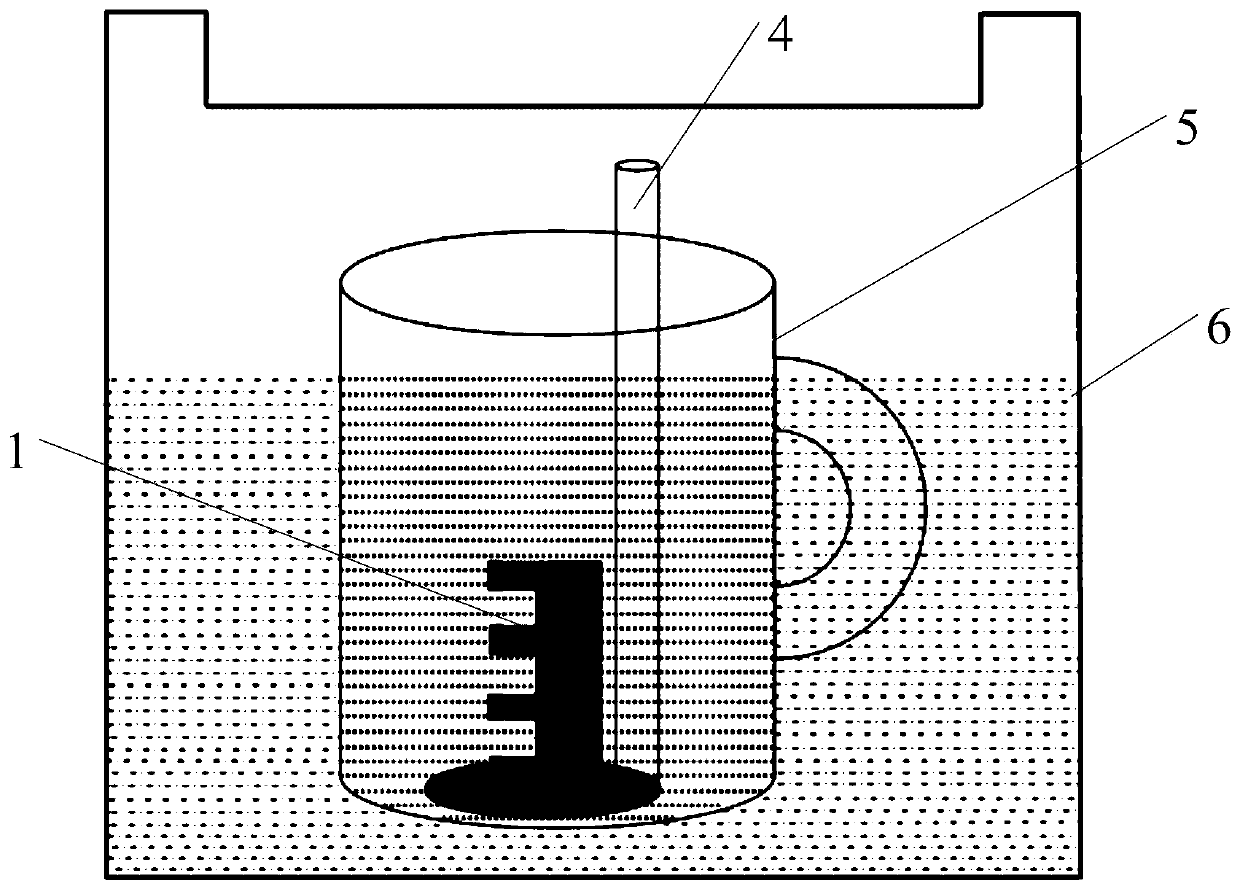

[0039] First soak in acetone solution at room temperature and clean with low-power ultrasonic waves, then soak in high-temperature acetone solution and clean with high-power ultrasonic waves, so that all photoresists on semiconductors with nano-sized photoresists can be cleaned with low energy consumption. Clean up.

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com