Stress-loading three-dimensional test device and method for analyzing stability of shield tunneling faces

A technology of stress loading and test device, which is applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., which can solve the problem of not truly reflecting the three-dimensional soil stress-strain relationship, stress environment differences, and reliable analysis results. Sexual doubts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

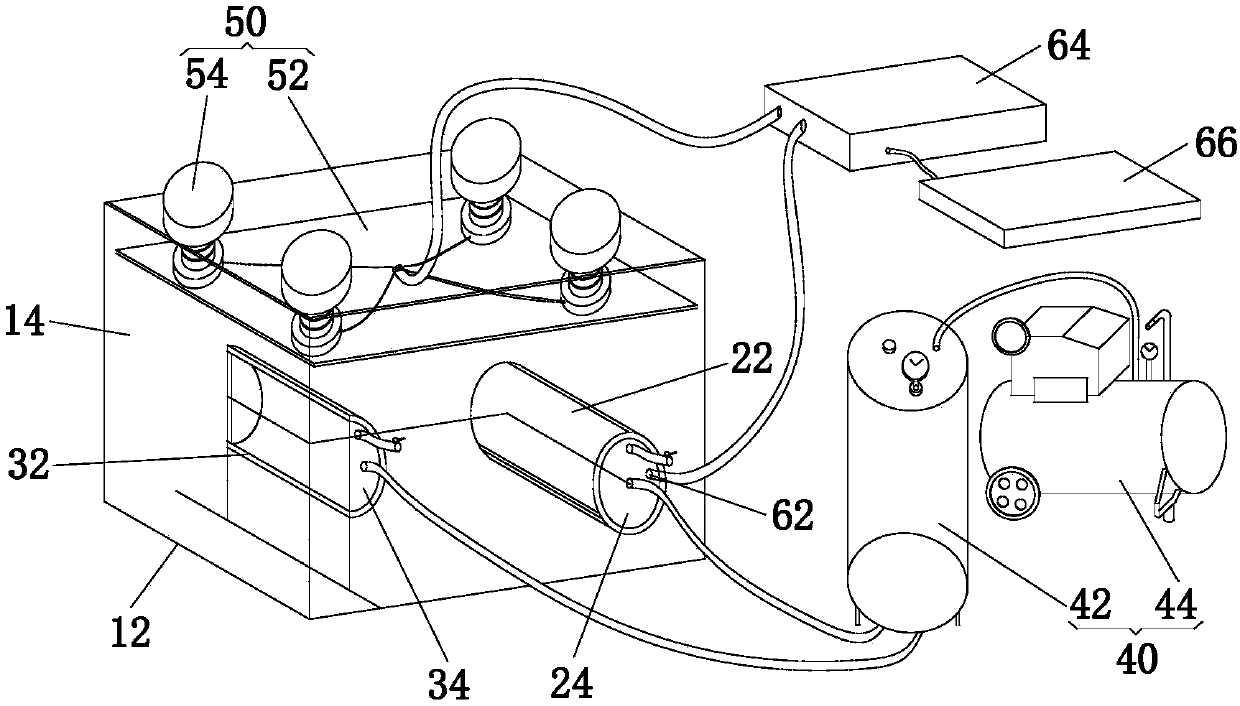

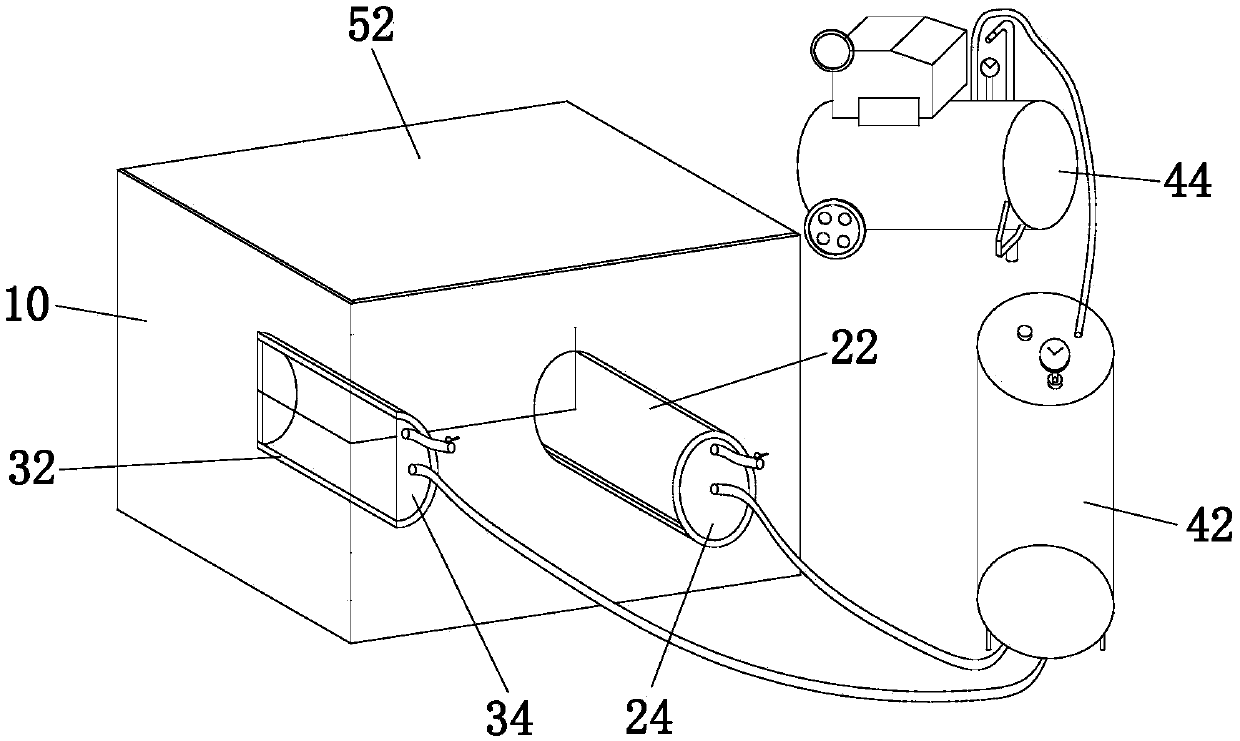

[0040] see figure 1 and figure 2 As shown, the present invention proposes a stress-loaded three-dimensional test device for the stability analysis of the shield tunneling surface, which is used to simulate the stability analysis of the mud-water shield tunneling surface. The three-dimensional test device for the shield tunneling surface includes a housing 10, a confining pressure simulation Mechanism 50, stress synchronous loading mechanism 40, at least two filling and measuring components.

[0041] The housing 10 includes a bottom wall 12, a side wall 14 and a top wall, the bottom wall 12 is closed at the lower end opening of the side wall 14, and the top wall is detac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com