Dam punning equipment

A technology of dams and equipment, which is applied in the field of damming equipment, and can solve the problems of dams not being rammed and reinforced, dam piping, and dyke breaks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

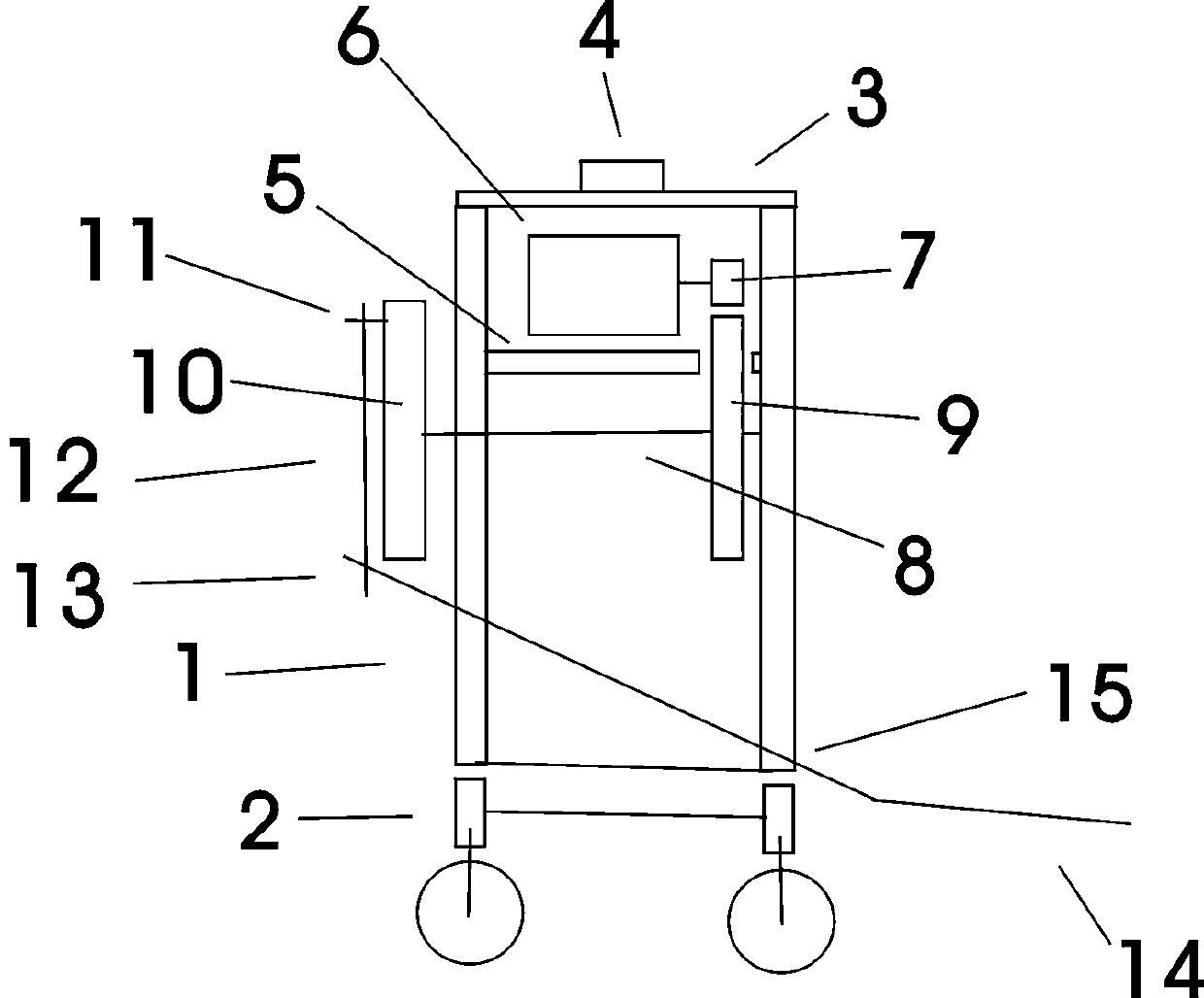

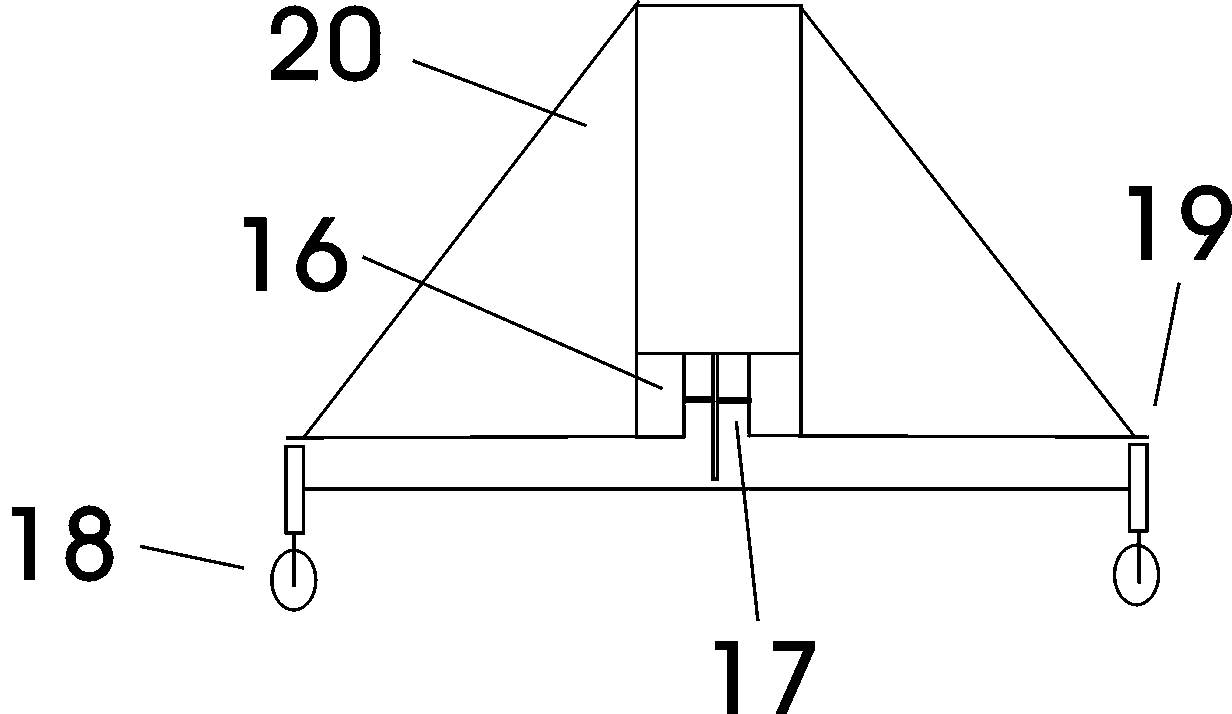

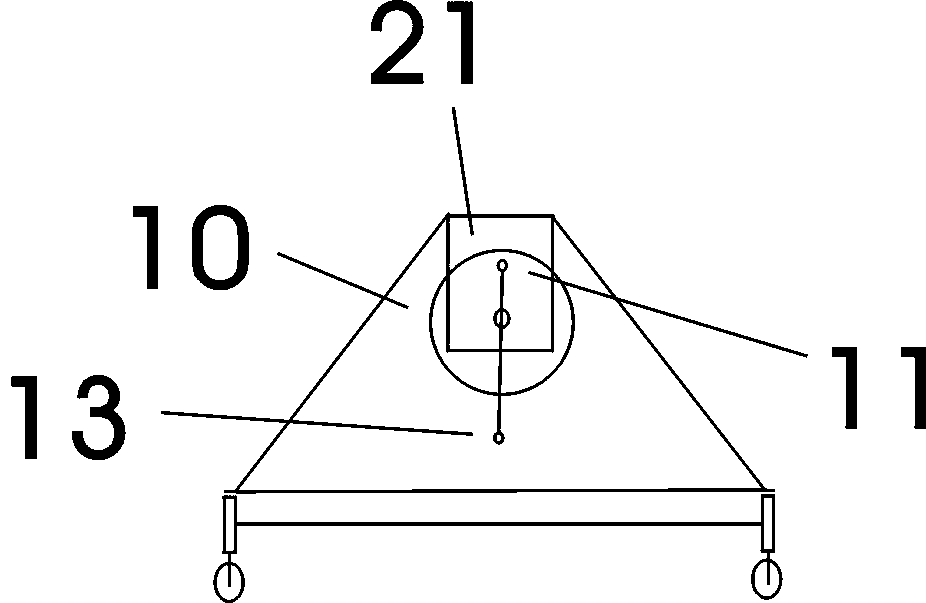

[0019] To ram the embankment equipment, first fabricate a mounting frame. The installation frame is divided into upper frame 1 and base 2. The upper shelf of the mounting bracket looks like a trapezoid from the front. It looks like a rectangle from the side. The top plate 3 on the mounting frame is the screw hole part 4 that is set on the top of the trapezoid and the same as the screw hole part of the bucket butt joint arm of the excavator. After the excavator removes the bucket, the stick, including the screw hole parts on the hydraulic equipment, can be connected with the screw hole parts provided on the top plate of the mounting bracket through screws. Also, the hydraulic arm of the excavator can control the upper frame of the mounting frame to rotate in the front and rear directions.

[0020] Power machine 6 is set under the top plate of the upper shelf on the mounting frame. A pinion 7 is installed on the rotating shaft of power machine. The power machine is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com