Crayfish grading and screening device based on machine vision detection

A technology of machine vision detection and visual detection device, which is applied in sorting and other directions, can solve the problems of high labor intensity, large error in the projection area of crayfish and shrimp body, and time-consuming, so as to improve the detection accuracy, improve the detection accuracy, and reduce the score. The effect of picking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

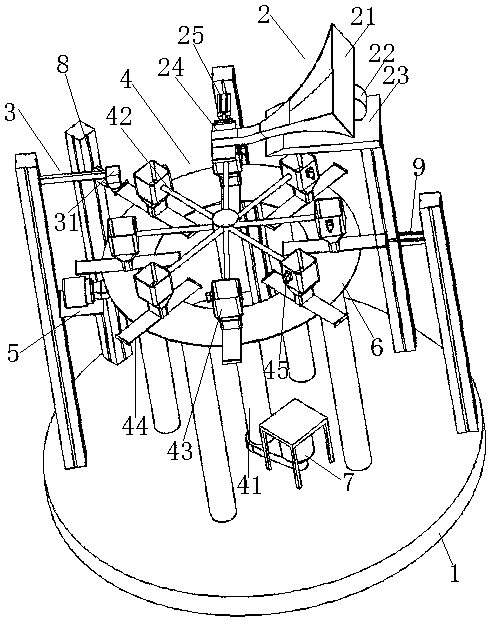

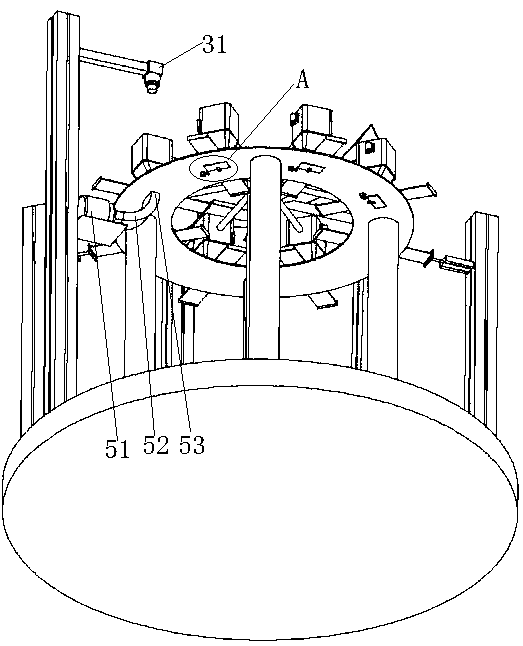

[0035] Combined with specific attachments Figure 1-6 Briefly describe the design process of the present invention:

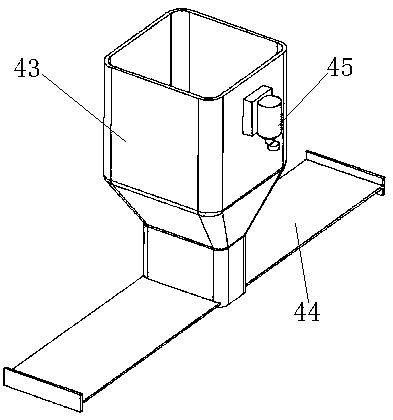

[0036] The vibrating hopper 21 of the present invention has a wide top and a narrow shape with an open mouth. The narrowest position on the bottom can only accommodate one crayfish of 15 to 40 grams. The bottom surface of the outlet has at least two crayfish lengths, bottom surface and horizontal plane. Parallel, the discharge port below the end of the vibrating hopper 21 is a rectangular opening the size of a crayfish can pass through. The opening can be opened and closed by the blanking cylinder 25 and the baffle B24. The vertical turret 41 has a total of eight material boxes 43 fixed on the horizontal hanging rod 42, corresponding to eight stations. The counterclockwise direction along the station disk 6 is the loading position, the adjustment and discharge level, the detection station, Blanking station A, blanking station B, blanking station C, reset station,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com