Filling fire-fighting battery module storage and charge-discharge box system

A battery module, charging and discharging technology, applied in the direction of secondary battery charging/discharging, battery pack components, battery and its environment isolation, etc., can solve the problem of only suppressing the flame, but cannot completely extinguish the fire, and achieve the effect of convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

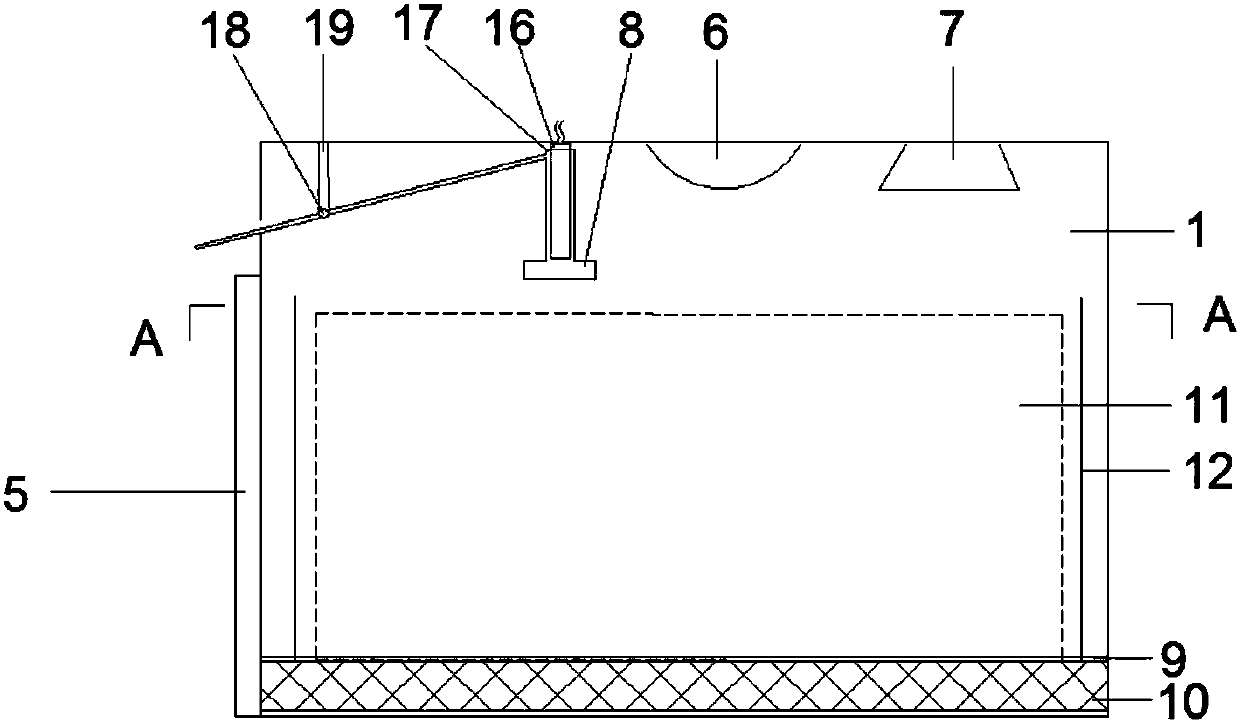

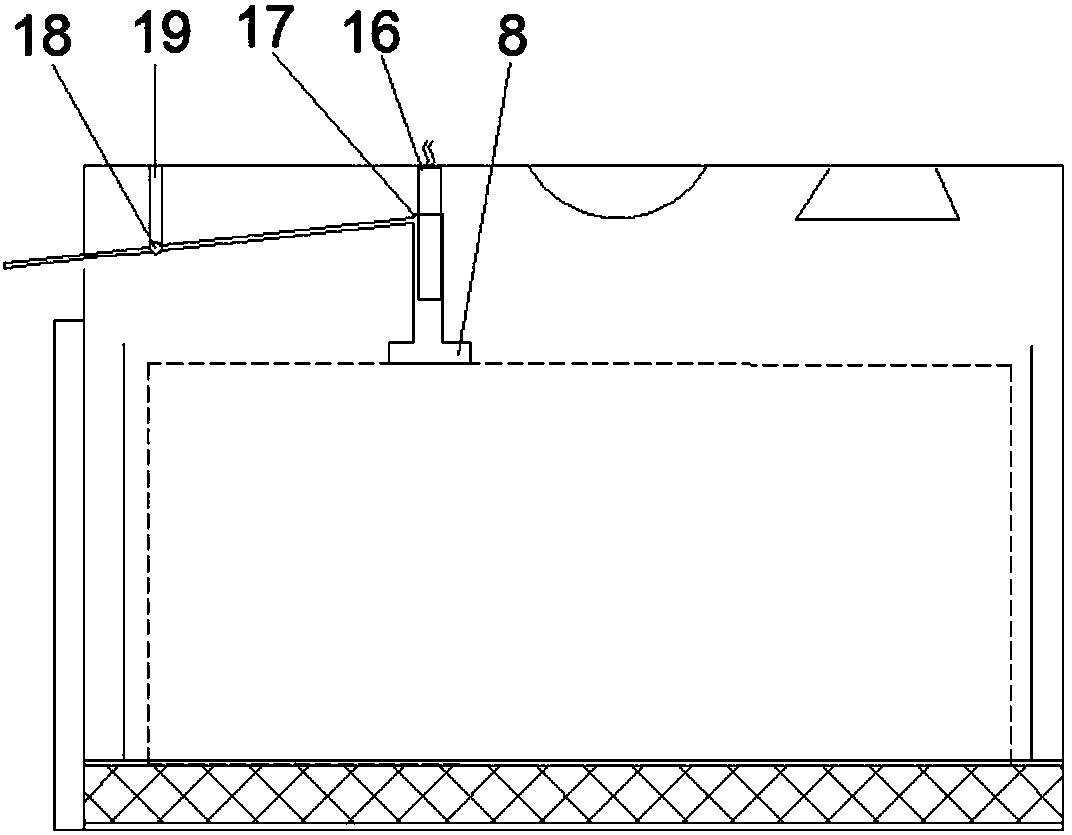

[0037] Such as Figure 1-7 , a battery module storage and charging and discharging box system for liquid-filled fire protection, including a box system composed of one or more boxes 1 and a power supply 2 connected to the box system, a liquid storage tank 3, and a control system Module 4; the box body 1 includes a warehouse door 5 located at the front end of the box body, a composite sensor 6 located at the top inside the box body, a fire sprinkler 7 and a charging socket 8 located inside the box body, and set on the side wall of the box body The chute 9, the tray 10 that can slide in the chute, the liquid storage box 12 that is arranged on the top opening of the tray for placing the battery 11; the charging socket 8 is connected to the controllable on-off switch 13 and then connected to the power supply 2 , the preferred controllable on-off switch of the present embodiment is a contactor; all fire sprinklers 7 are respectively connected with a control valve 15 and then aggreg...

Embodiment 2

[0047] Such as Figure 8 The difference from Embodiment 1 is that the charging socket 8 of this embodiment is located on the side wall of the liquid storage box 12 inside the box, and is connected to the controllable on-off switch 13 through the openings on the liquid storage box and the side wall of the box.

Embodiment 3

[0049] Such as Figure 9 The difference from Embodiment 1 is that the charging socket 8 of this embodiment is located at the bottom of the liquid storage box 12 inside the box, and is connected to the controllable on-off switch 13 through the openings opened on the liquid storage box, the tray, and the bottom of the box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com