Fuel cell individual assembly device

An assembly device and fuel cell technology, applied in the direction of solid electrolyte fuel cells, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of core component test analysis errors, complex assembly process, high cost, etc., to save time and The cost, the assembly process is simple, and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

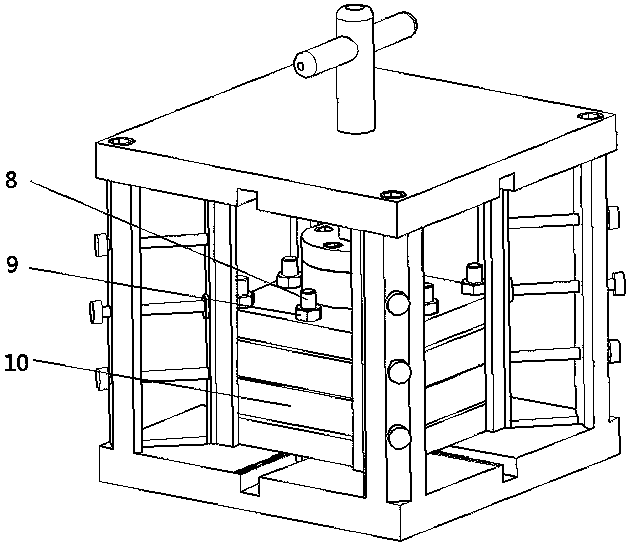

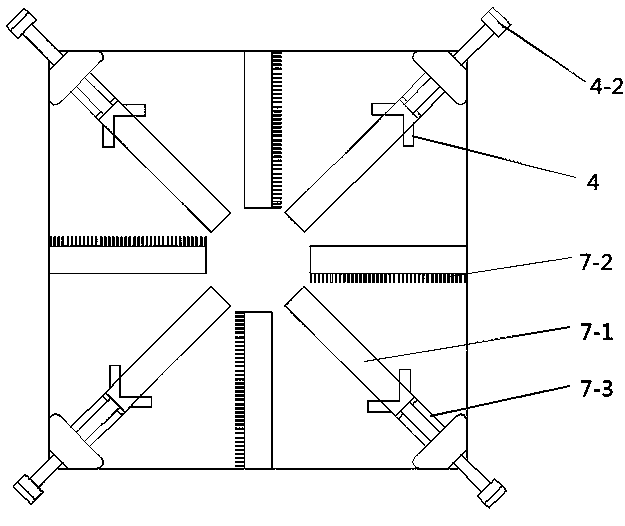

[0025] Such as figure 1 As shown in the figure, the present invention provides a single fuel cell assembly device, which consists of a screw pressure rod 1, an upper end plate 2 of the device, a column of the device frame 6, a pressure plate 5, a movable slider 4, and a threadless push rod 4- 2. It is composed of the fixed screw rod and the lower end plate 7 of the device. The upper end plate 2 of the device and the lower end plate 7 of the device are square plate-shaped structures with the same side length, and there are four upright columns 6 of the device frame. Column 6 is fixed into integral frame. The spiral pressure rod 1 is mounted on the center position of the upper end plate 2 of the device, and the upper end of the spiral pressure rod 1 is provided with a horizontal rod-shaped handle. The pressure plate 5 is a circular plate, which is installed at the lower end of the screw pressure rod 1. The pressure sensor is installed in the pressure plate 5, which can accurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com