A locomotive wind pressure and flow monitoring device and method

A technology of flow monitoring and air flow, which is applied in the direction of measuring devices, instruments, signal transmission systems, etc., can solve the problems of low total air pressure, insufficient air supply capacity of the total air cylinder, and failure to determine the air output flow of the locomotive dryer, etc., to achieve The effect of reducing potential safety hazards, improving reliability and practicability, and improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

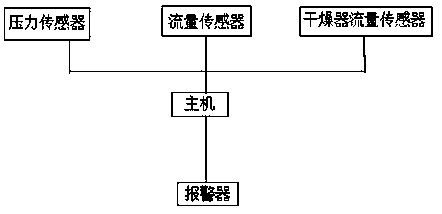

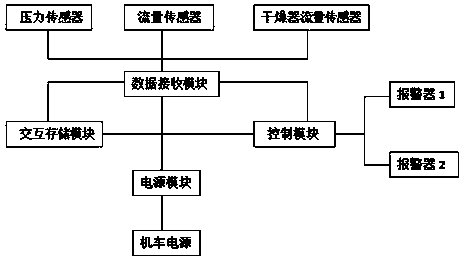

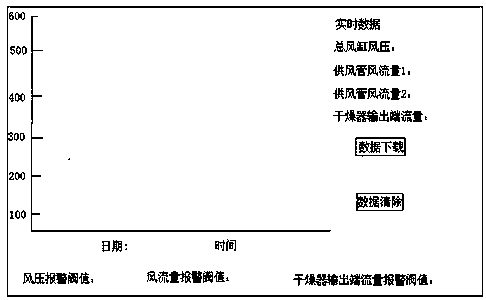

[0026] Attached below Figures 1 to 3 Embodiments of the present invention are described in detail.

[0027] The locomotive wind pressure and flow monitoring device is characterized in that it includes a pressure sensor for collecting real-time data of the wind pressure of the locomotive main air cylinder, a flow sensor for collecting real-time data of the air flow of the locomotive air supply pipe, and can adjust the total air flow of the locomotive according to the operating needs of the locomotive. The alarm threshold of cylinder air pressure and locomotive air supply pipe air flow is preset to the host and the alarm connected to the host signal. The host is connected to the pressure sensor and flow sensor for data transmission to receive and display real-time data. If the real-time data of the wind pressure or the real-time data of the wind flow is less than or equal to its corresponding alarm threshold, the alarm is controlled to send out an alarm.

[0028] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com