Multi-nozzle ejector for inflating civil aircraft slides

A multi-nozzle and ejector technology, used in aircraft parts, ejection/off-aircraft devices, transportation and packaging, etc., can solve the problems of difficult manufacturing and assembly, low ejection efficiency, complex structure, etc., to reduce packaging volume and Weight, improve ejection efficiency, avoid mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

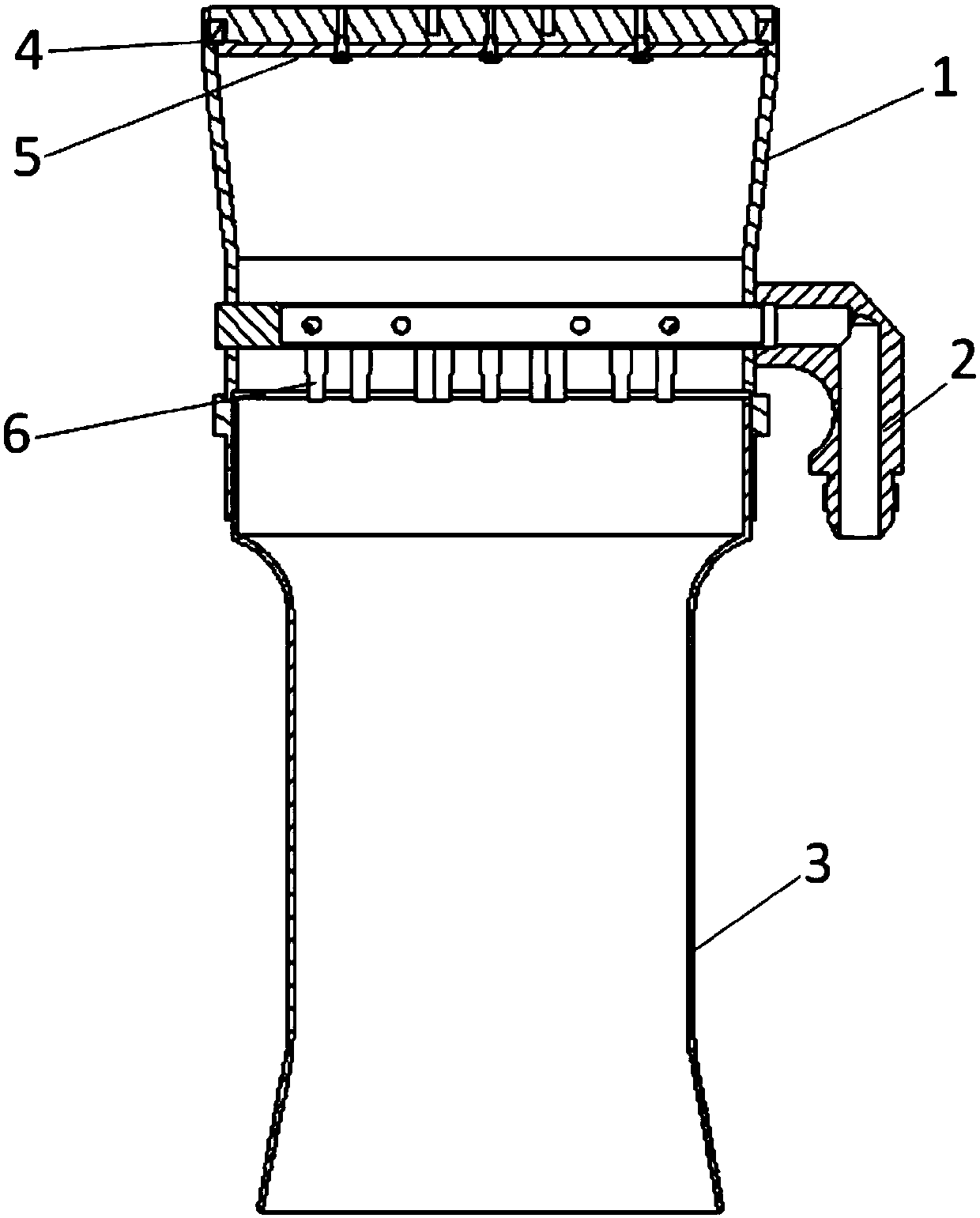

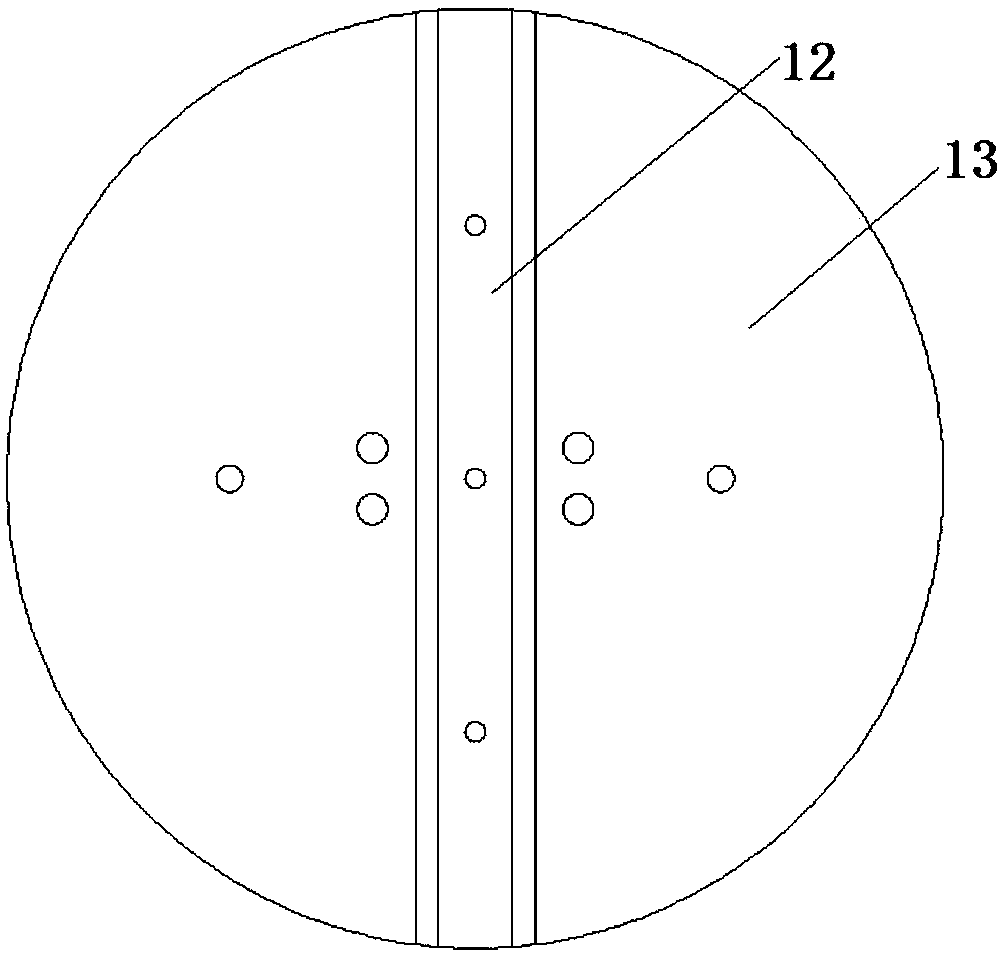

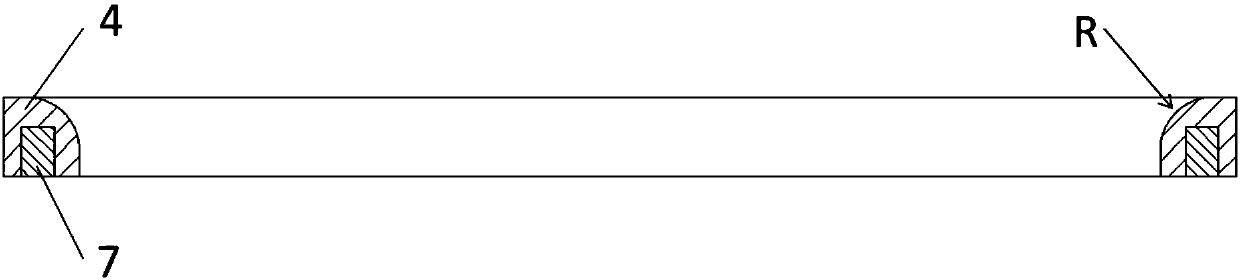

[0026] refer to Figure 1 to Figure 5 As shown, the multi-nozzle ejector for civil aircraft slide inflation in an embodiment provided by the present invention includes a suction chamber and a mixing chamber, the lower end of the suction chamber is socketed with the upper end of the mixing chamber, and the gap between the suction chamber and the mixing chamber There is a nozzle assembly between them, the air inlet at the upper end of the suction chamber is provided with a shut-off valve, the inlet end of the nozzle assembly is connected with a high-pressure gas interface, the nozzle assembly includes a plurality of nozzles, and the nozzles communicate with the mixing chamber; Inflatable port Unicom;

[0027] Wherein, the nozzle assembly includes a plurality of concentrically arranged annular air intake branches and main air intake pipes, the main air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com