High-strength sharp-nose pliers

A needle-nose pliers, high-strength technology, applied in the direction of pliers, cable installation devices, electrical components, etc., can solve the problems of reducing work efficiency, affecting work results, and easy slipping of needle-nose pliers, so as to prevent slipping, improve work efficiency, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

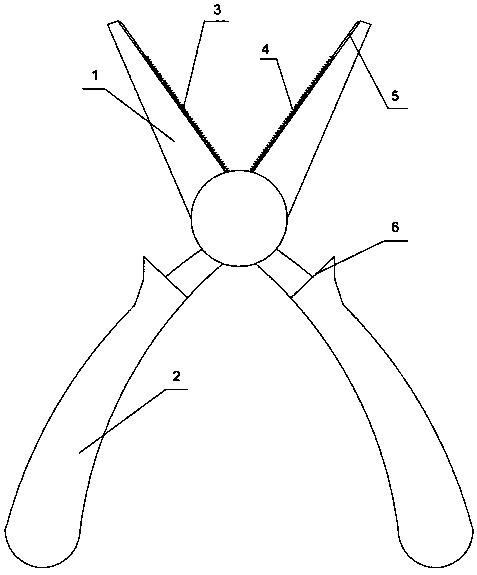

[0013] like figure 1 As shown, a high-strength needle-nose pliers includes a jaw 1 and a handle 2. The jaw 1 includes a left jaw and a right jaw that cooperate with each other. The clamping surface 3 of the jaw 1 near the handle 2 is provided The horizontal groove-shaped tooth pattern 4 parallel to the width direction of the pliers mouth 1, the clamping surface of the end of the pliers mouth 1 away from the pliers handle 2 is provided with a longitudinal groove-shaped tooth pattern 5 parallel to the length direction of the pliers mouth 1, and the The longitudinal grooved teeth 5 are evenly distributed on the clamping surface 3, the distribution density of the longitudinal grooved teeth 5 on the left jaw is greater than the distribution density of the longitudinal grooved te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com