Metal pipeline corrosion detection technology based on multi-frequency AC field fingerprint method based on phase recognition

A metal pipe and phase recognition technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of being susceptible to drift interference, unable to measure the absolute defect depth, etc., and achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] An implementation example of the present invention is described in detail as follows:

[0030] The present invention is a metal pipeline defect detection technology of the multi-frequency AC field fingerprint method, and the specific implementation steps are as follows:

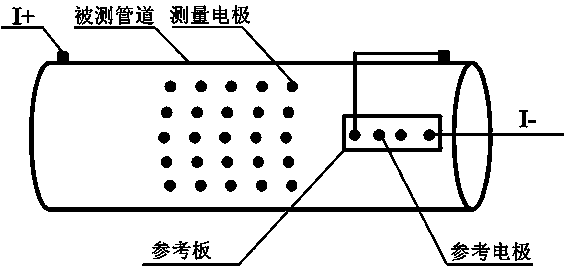

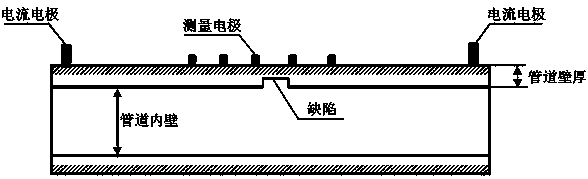

[0031] (1) Select an ordinary carbon steel pipe with a wall thickness of 10mm, a pipe diameter of 219mm, and a length of 1000mm as the measured object, weld a pair of current excitation electrodes at both ends of the pipe, and weld and install the measuring electrode matrix on the outer wall of the pipe center, The distance between electrodes measured in the axial direction is 35mm;

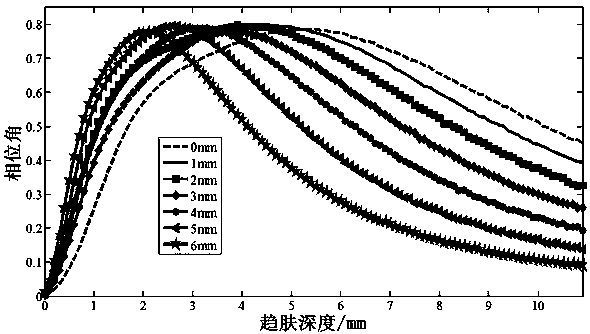

[0032] (2) Process defects with a depth of 1mm, 2mm, 3mm, 4mm, 5mm and 6mm on the inner wall of the pipeline corresponding to the measuring electrode, and the size of the defect is 35mm×35mm;

[0033] (3) According to the material characteristics of the pipeline under test, adjust the frequency of the excitation current,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com