Winding machine

A technology of winding machine and winding motor, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of difficult replacement of wire reels, low cost of reel replacement, and long time spent. Achieve the effect of realizing automation improvement and realizing fully automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings.

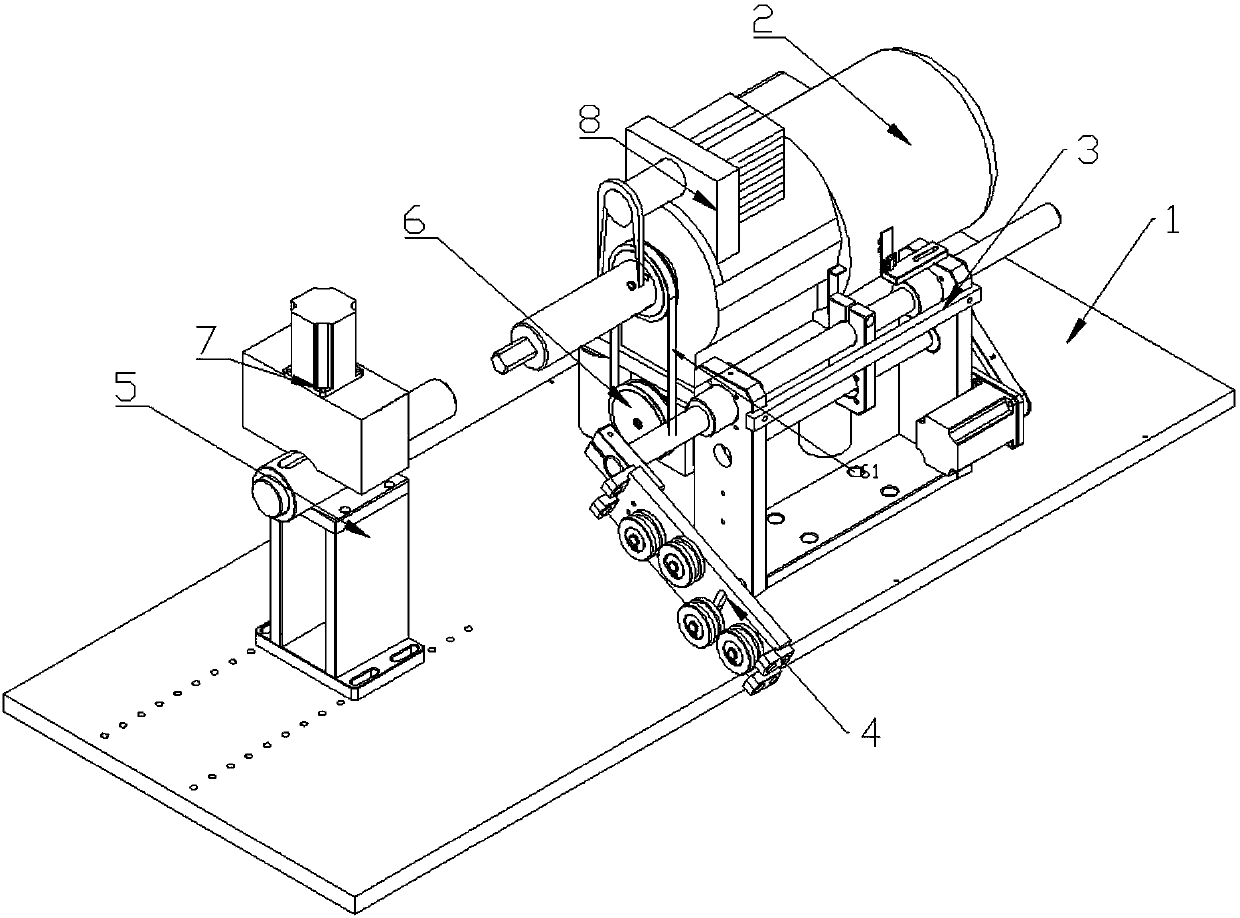

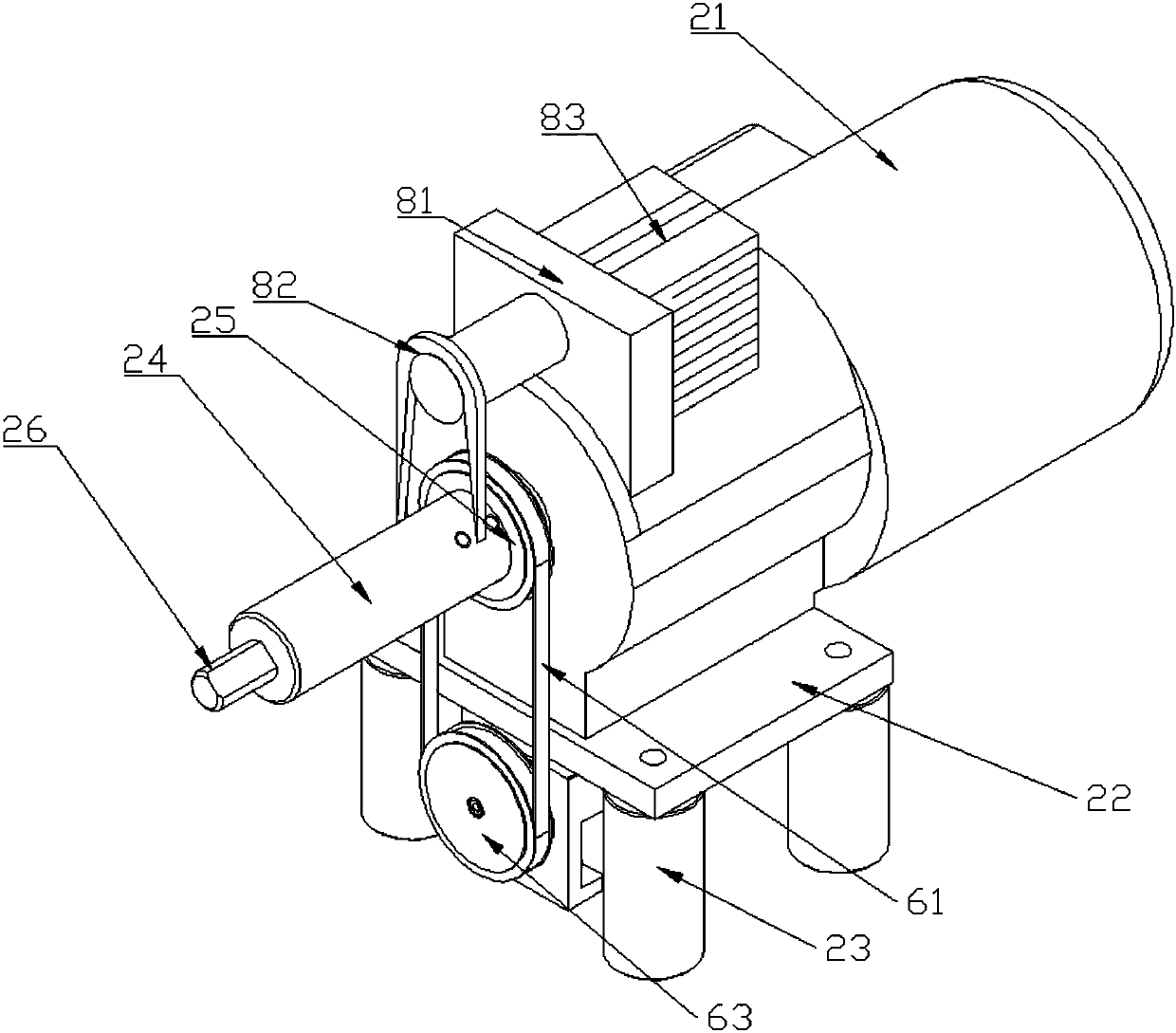

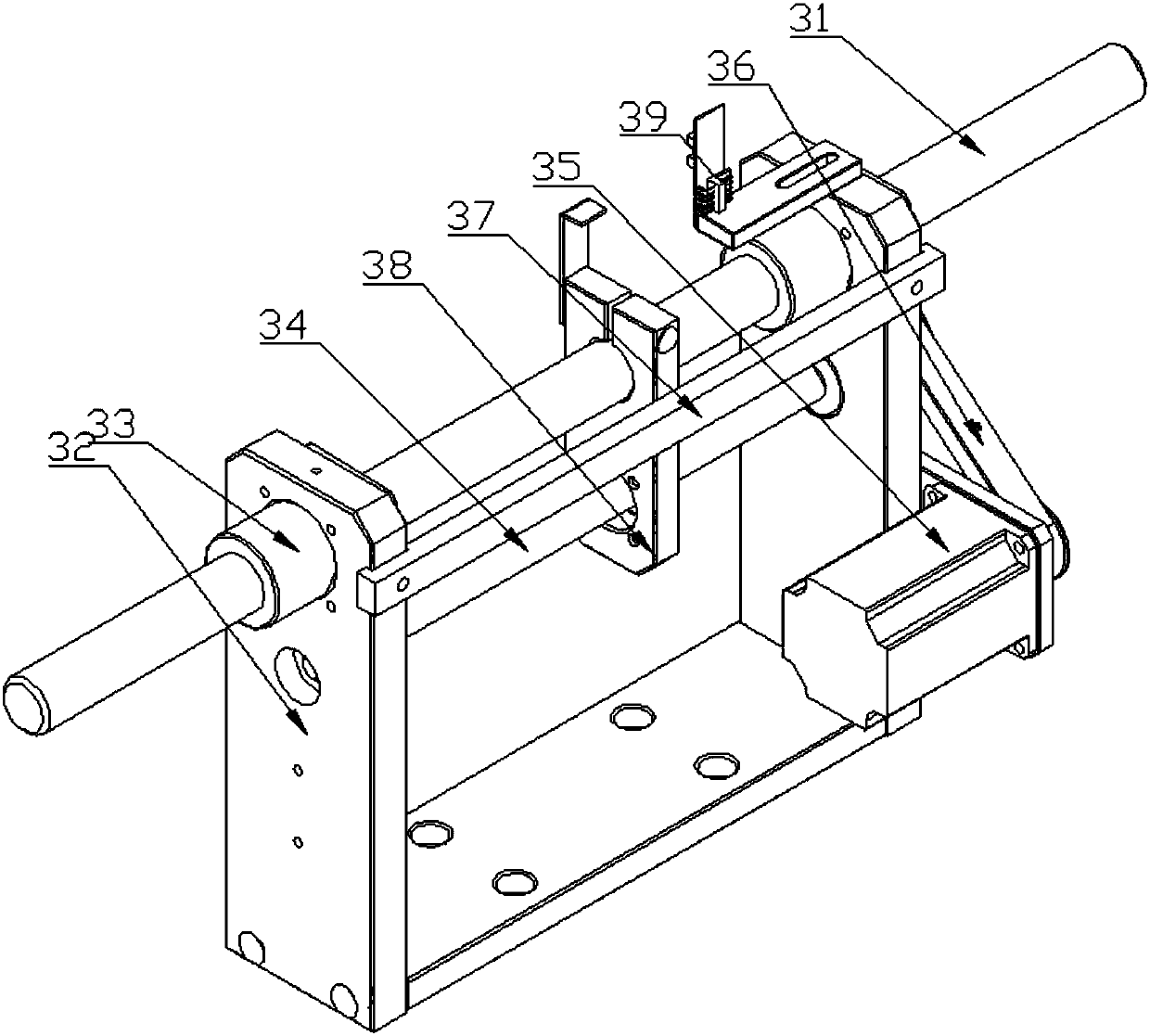

[0023] figure 1 It is a schematic structural view of the winding machine of the present invention, as figure 1 As shown, a winding machine includes a base plate 1 on which a winding part 2, a wire feeding part 3, a wire material fixing part 4 and a pressing part 5 are installed, and the feeding part 3 is located on the winding One side of the wire part 2, the wire material fixing part 4 is fixed on the front end of the wire feeding part 3 through the optical axis 31, the pressing part 5 is located in front of the wire winding part 2, and the wire winding part 2 The bottom end is equipped with an induction part 6, and one side of the pressing part 5 is equipped with an automatic pressing mechanism 7, and the induction part 6 is connected with the winding part 2 through a synchronous belt 61, and the automatic pressing mechanism 7 It is connected with the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com