Container special for construction site spare and accessory parts

A technology for building construction and spare parts, which is applied in the field of building parts storage equipment, can solve problems such as hindering the appearance of the warehouse, management confusion, difficult first-in first-out management methods, etc., to facilitate distinction and identification, reduce excessive occupation, and use The effect of three-dimensional space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

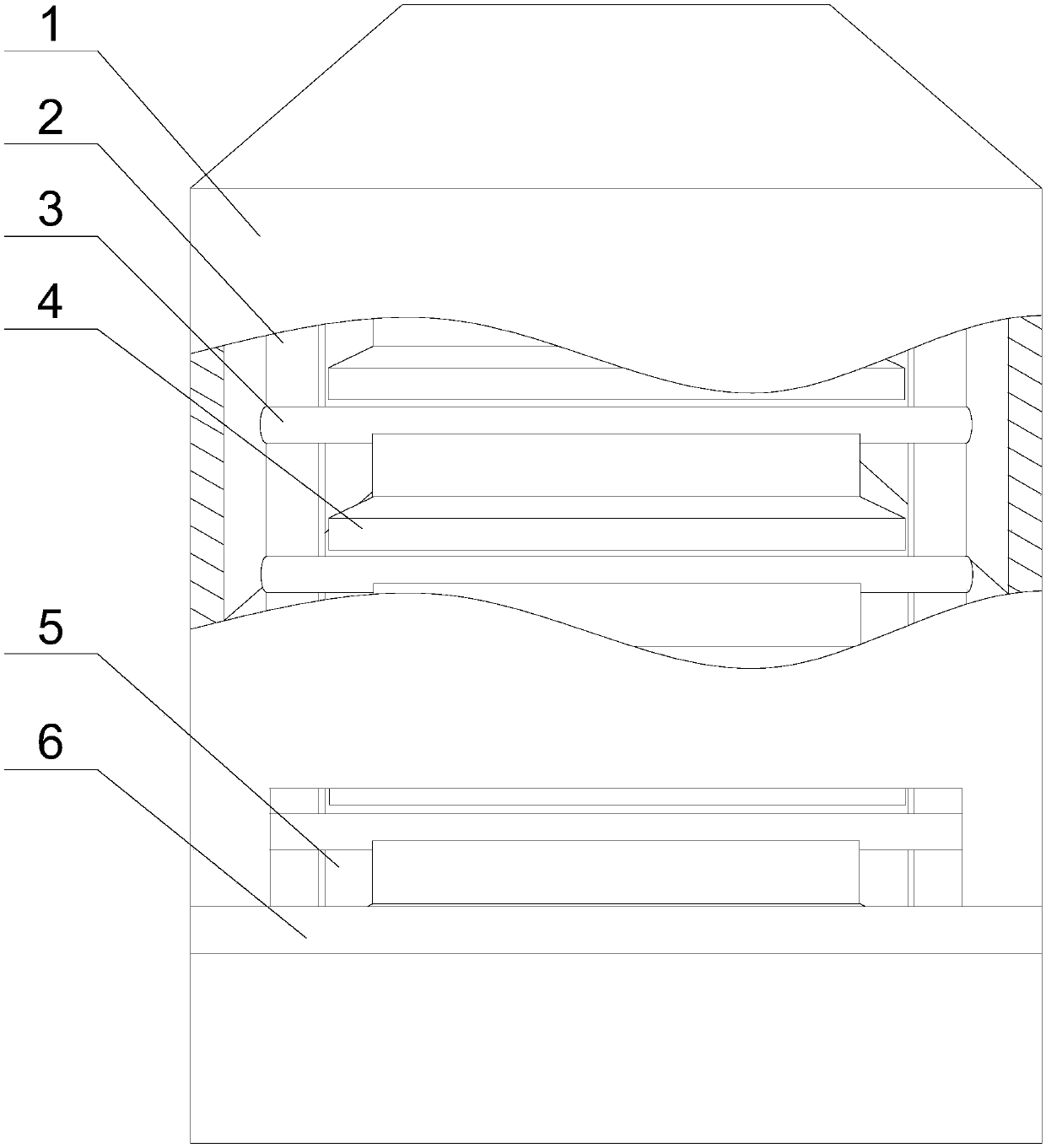

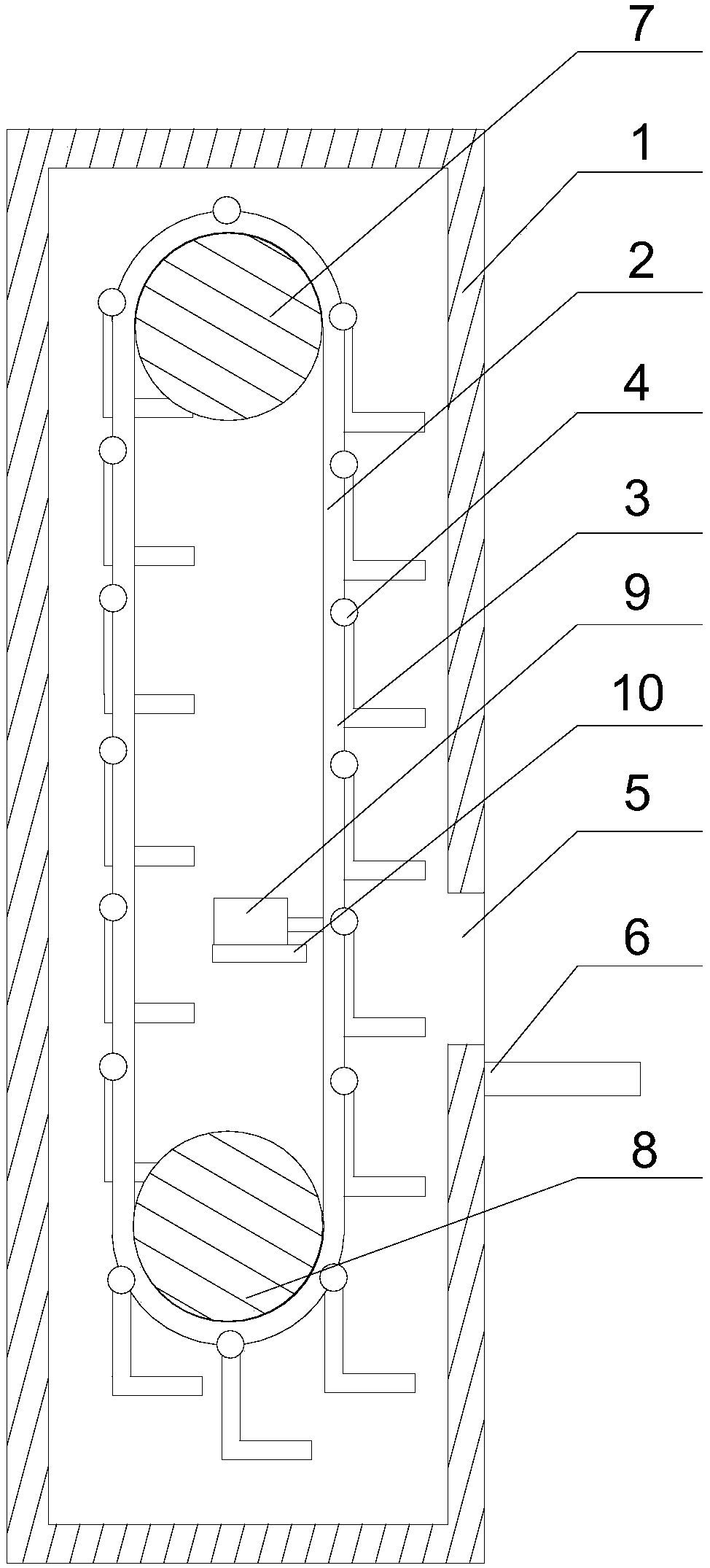

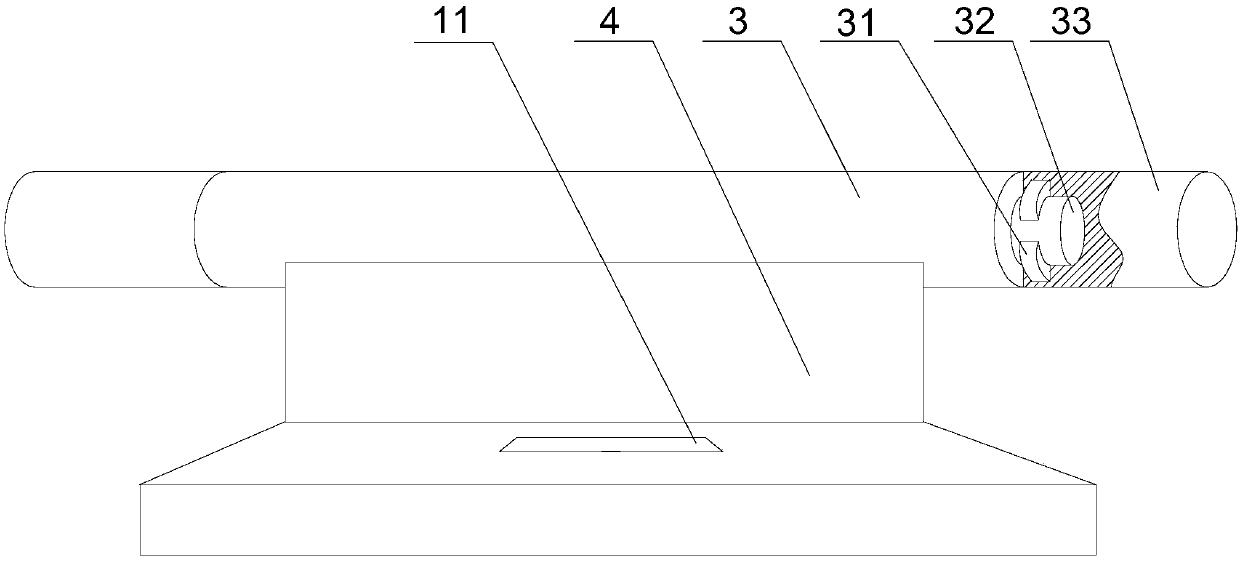

[0022] Such as Figure 1 ~ Figure 4 As shown, the present embodiment includes a cabinet body 1, two motors and two groups of main sprocket 8 and driven sprocket 7 which are arranged on the inner wall of the cabinet body 1 for rotation, and the main sprocket 8 and driven sprocket 7 pass through the chain 2 Connection and cooperation, the output end of the motor is connected to the main sprocket 8, and the cabinet body 1 is provided with a delivery port 5, and also includes a plurality of rotating shafts 3 and a cylinder 9, and the cylinder body 9 is fixed inside the cabinet body 1 through a support plate 10 , the rotating shaft 3 is composed of a main body located in the middle section and fixed sections 33 at both ends. A hopper 4 is fixed on the main body. 9. The pressure sensor 11 connected to the control element, the fixed section 33 is embedded in the chain 2, and the fixed section 33 is provided with a movable cavity 34 with an elliptical cross section, which is extended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com