Electric tool box system for boring lathe

An electric type and tool box technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of hot boring machine running, interference of rotating shaft mechanism and lubrication mechanism, etc., and achieve the effect of avoiding hot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

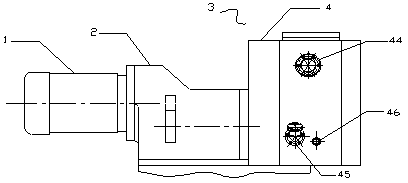

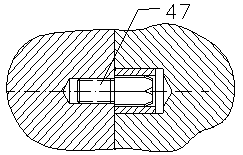

[0018] Such as Figure 1 to Figure 3 An electric tool box system for a boring machine is shown. The electric tool box system for a boring machine includes a motor 1, a gearbox 2 and a headstock 3, and the motor 1, the gearbox 2 and the headstock 3 are connected in sequence.

[0019] The motor 1 is connected to the input end of the gearbox 2 , and the output end of the gearbox 2 is connected to the main shaft box 3 .

[0020] The spindle box 3 is a box structure, including a casing 4 , a rotating shaft mechanism 5 and a lubricating mechanism 6 , and the lubricating mechanism 6 and the rotating shaft mechanism 5 are installed inside the casing 4 .

[0021] The casing 4 includes an upper cover 41, a bottom case 42 and surrounding side covers 43; one side cover 43 has an oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com