Multi-emulsion preparation system

A technology for preparing a system and multiple emulsions, which is applied in the field of multiple emulsion preparation systems with cyclic overflow structure characteristics, can solve the problems of low preparation efficiency and poor batch stability, and achieves improved stability, stable preparation, and enhanced pressure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

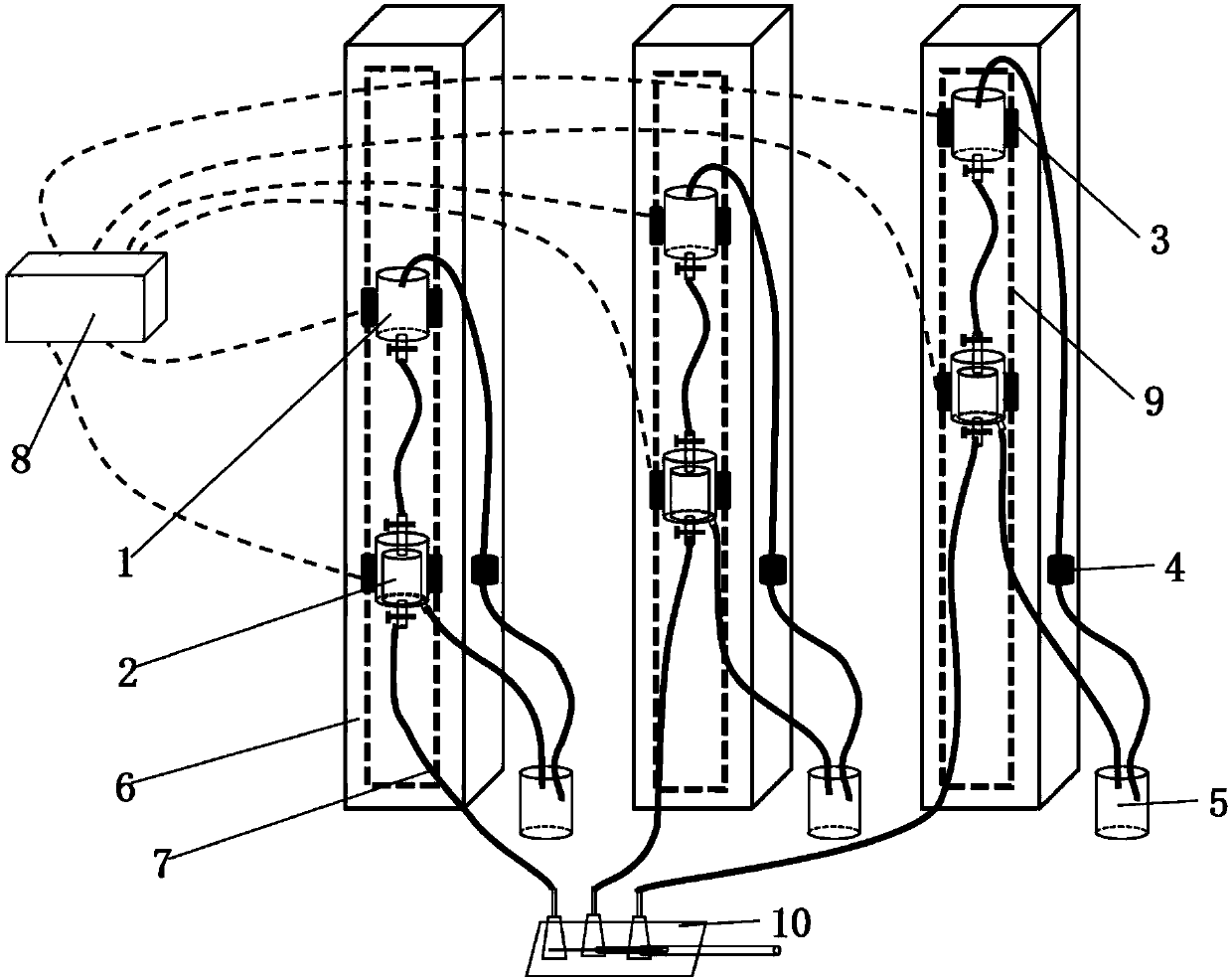

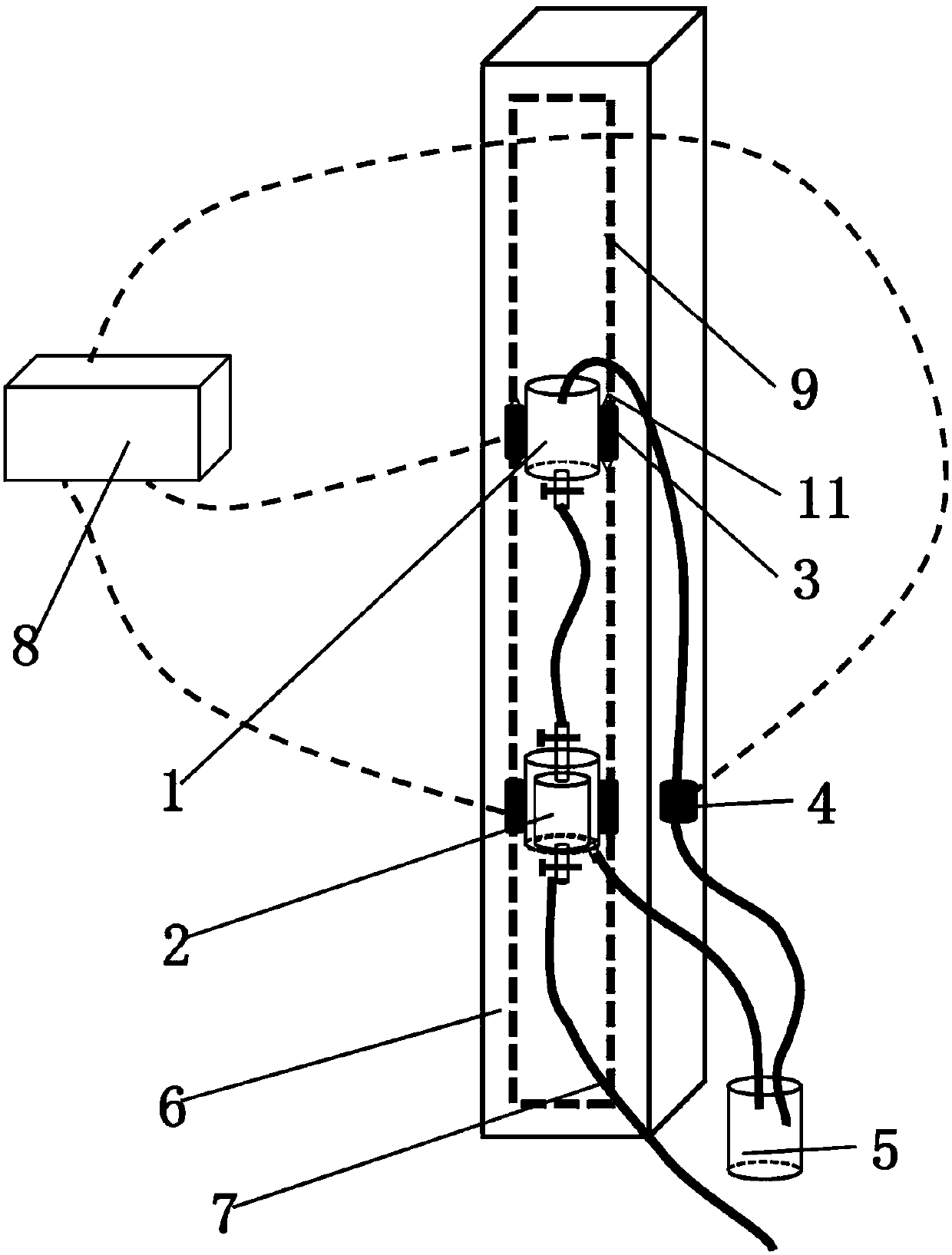

[0030] A kind of multiple emulsion preparation system under the unattended condition continuous and stable preparation of water-in-oil-in-water double emulsion specific implementation steps:

[0031] (1) To prepare related solutions, 2% F108 aqueous solution can be used for the inner phase, ETPTA can be used as the oil phase for the middle phase, and 2% PVA aqueous solution can be used for the outer phase.

[0032] (2) Add the prepared solution into the inner phase circulation bottle, the middle phase circulation bottle, and the outer phase circulation bottle correspondingly.

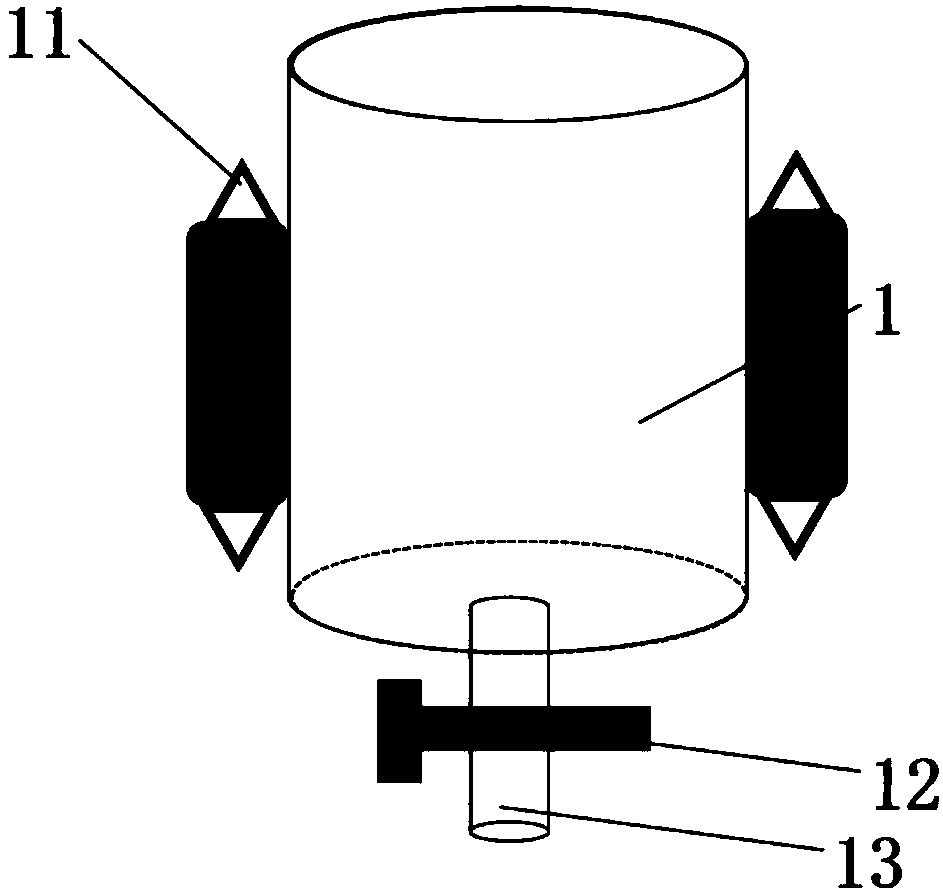

[0033] (3) Close all valves, open the controller, adjust the height of each corresponding buffer liquid storage device and overflow device, and use the controller to dynamically control the micropump, so that the flow of each phase is transported into the buffer liquid storage device.

[0034] (4) Open the valves of the outer phase buffer liquid storage device and the valve of the overflow device in seque...

Embodiment 2

[0035] Embodiment 2: The specific implementation steps of a multiple emulsion preparation system for continuous and stable preparation of oil-in-water-oil-in-water triple emulsion under unattended conditions:

[0036] (1) On the basis of the above-mentioned double emulsion preparation device, add a single-channel unit, and replace the microfluidic chip with a microfluidic chip for preparing triple emulsions to form a four-channel system

[0037] (2) Prepare relevant solutions, the water phase can be selected 2% PVA aqueous solution, and the oil phase can be selected ETPTA.

[0038] (3) Add the prepared solution to the first channel circulation bottle (oil phase), the second channel circulation bottle (water phase), the third channel circulation bottle (oil phase), and the fourth channel circulation bottle (water phase).

[0039] (3) Close all valves, open the controller, adjust the height of each corresponding buffer liquid storage device and overflow device, and use the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com