Pressing device for tire-building machines

A tire and structure technology, applied in tires, applications, household appliances, etc., can solve the problem that the surface extrusion force cannot be locally improved, and achieve the effect of reducing design costs and improving the stiffness against deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

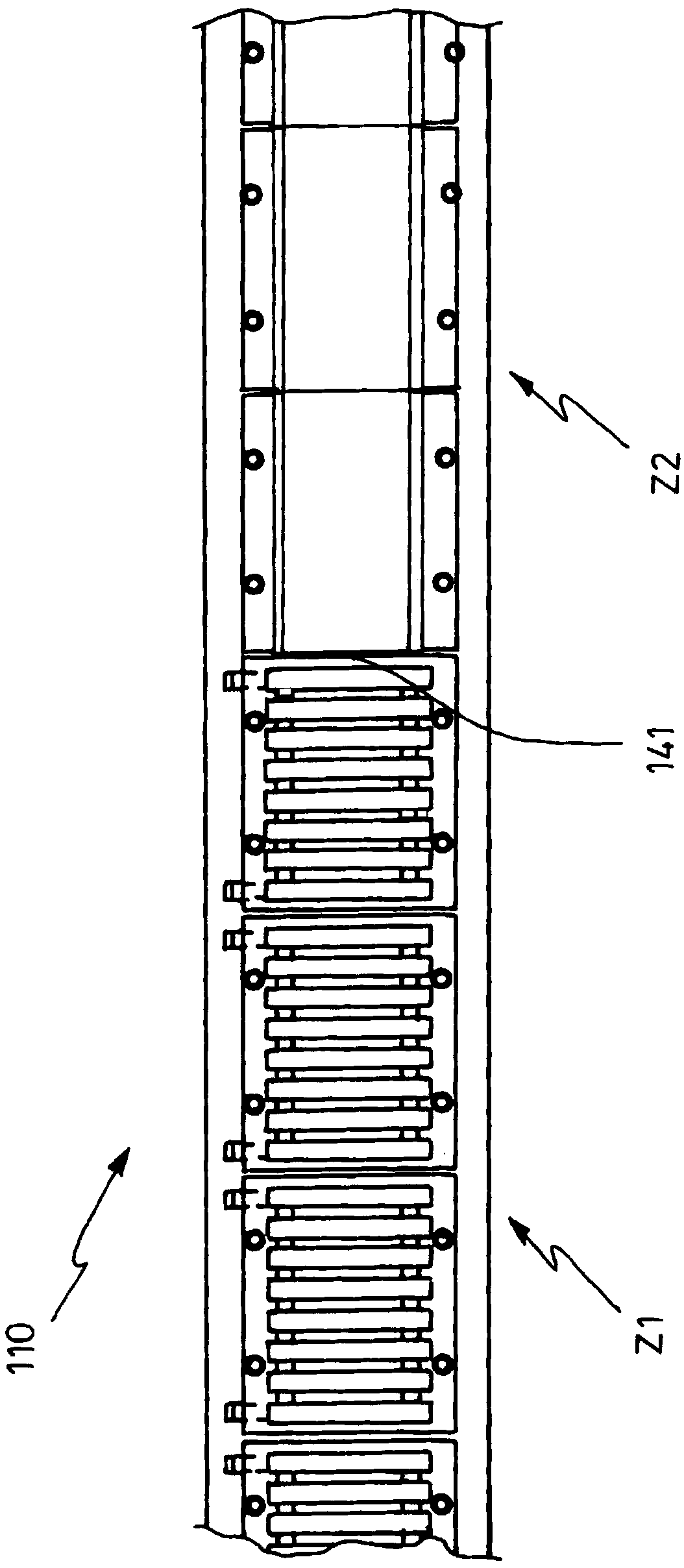

[0039] figure 1 The adjoining regions of the two zones ( Z1 , Z2 ) of the pressure bonding roller shaft ( 110 ) and the resulting zone contact points ( 141 ) are shown in a cross-sectional illustration. Exemplarily, the force loading devices of these zones are illustrated.

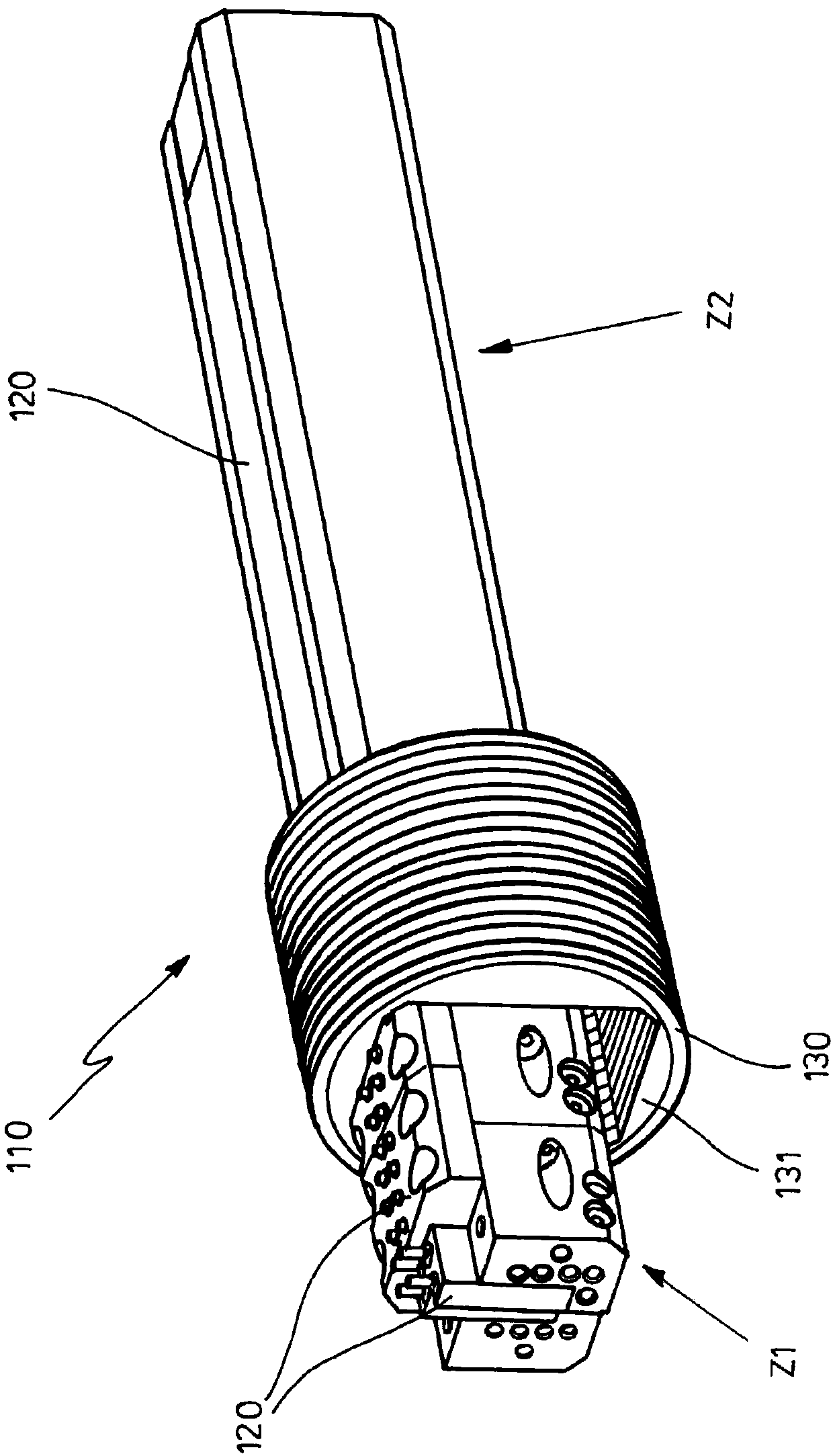

[0040] figure 2 Two zones ( Z1 , Z2 ) of the pressure-adhesive roller ( 110 ) are shown in perspective view with different force application devices ( 120 ) and an exemplary drawn diagram of several disc elements ( 130 ). In this exemplary embodiment, the cross-section of the pressure-adhesion roller ( 110 ) is embodied as a rectangle with chamfered edges.

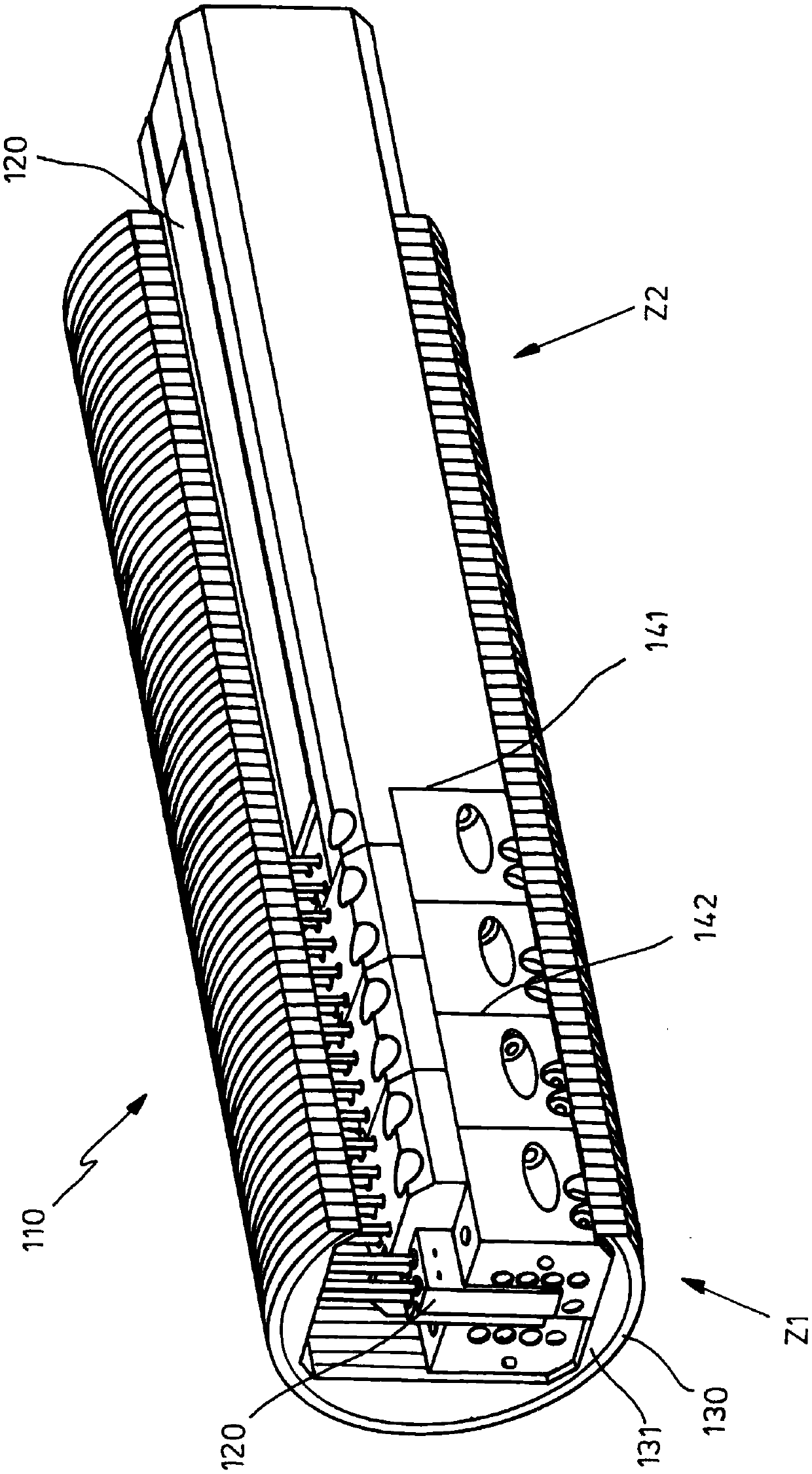

[0041] image 3 Two zones (Z1, Z2) of the press-on roller (110) are shown in perspective view, with different force loading devices (120) and a plurality of disc elements (130) under the force set by At least some of the force loading devices in the loading device (120) are in a final position after force loading.

[0042] Figure 4 Exemplary co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com