Product morphology detecting method based on Kinect

A shape detection and product technology, applied in the field of iterative three-dimensional reconstruction, can solve the problems of long measurement distance and low precision, and achieve the effect of reducing the false detection rate, easy layout and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

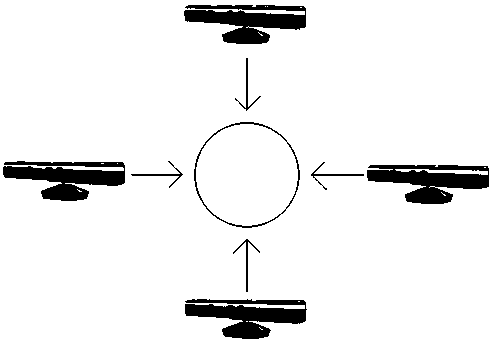

[0027] The present invention is realized in this way, the Kinect-based assembly line product shape detection method is characterized in that it is composed of three key parts: Kinect-based 4-camera calibration, depth data optimization and three-dimensional reconstruction.

[0028] One based on kinect camera calibration

[0029] Camera calibration has a direct relationship to the accuracy of measurement results. The more precise the calibration, the more accurate the final measurement will generally be. Since each lens has a different degree of distortion when it leaves the factory, a corrected image can be obtained through calibration. Another important reason is for 3D scene reconstruction. The present invention mainly calibrates four Kinect depth cameras.

[0030] For a single Kinect camera, Zhang Zhengyou’s checkerboard calibration method can be used directly, but this paper uses multiple Kinects. Due to the restriction of checkerboard placement, it is difficult for each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com