A Design Method for Axisymmetric Precompressed Precursor with Boundary Layer Displacement

A technology with boundary and pre-compression, which is applied to the combustion of the intake port of the power plant, supersonic aircraft, motor vehicles, etc., and can solve the problems of not considering boundary layer displacement, total shock wave pressure, short length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

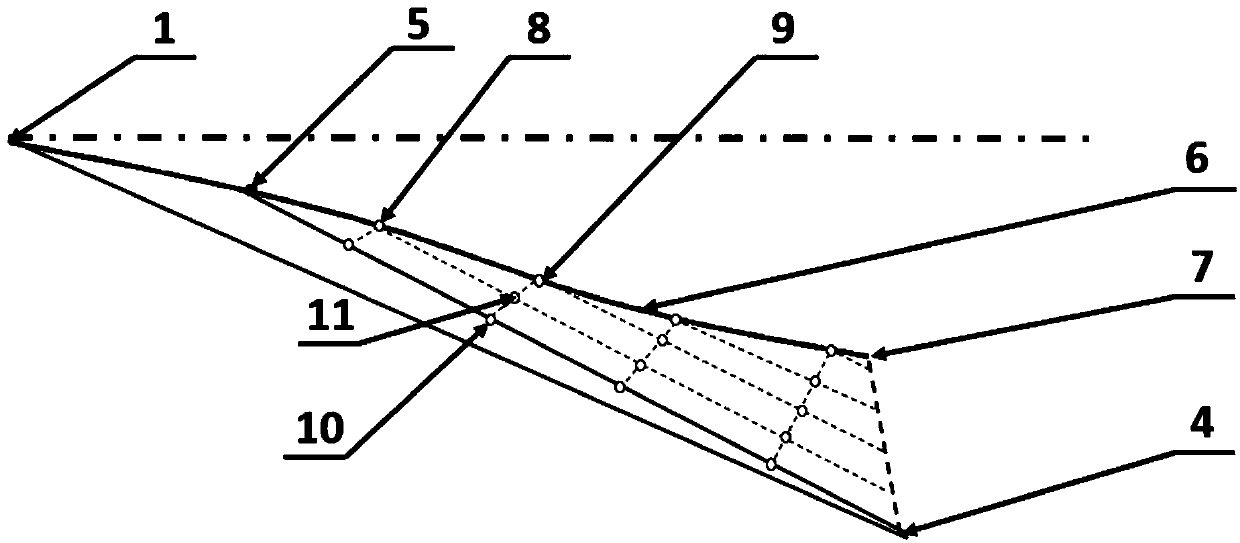

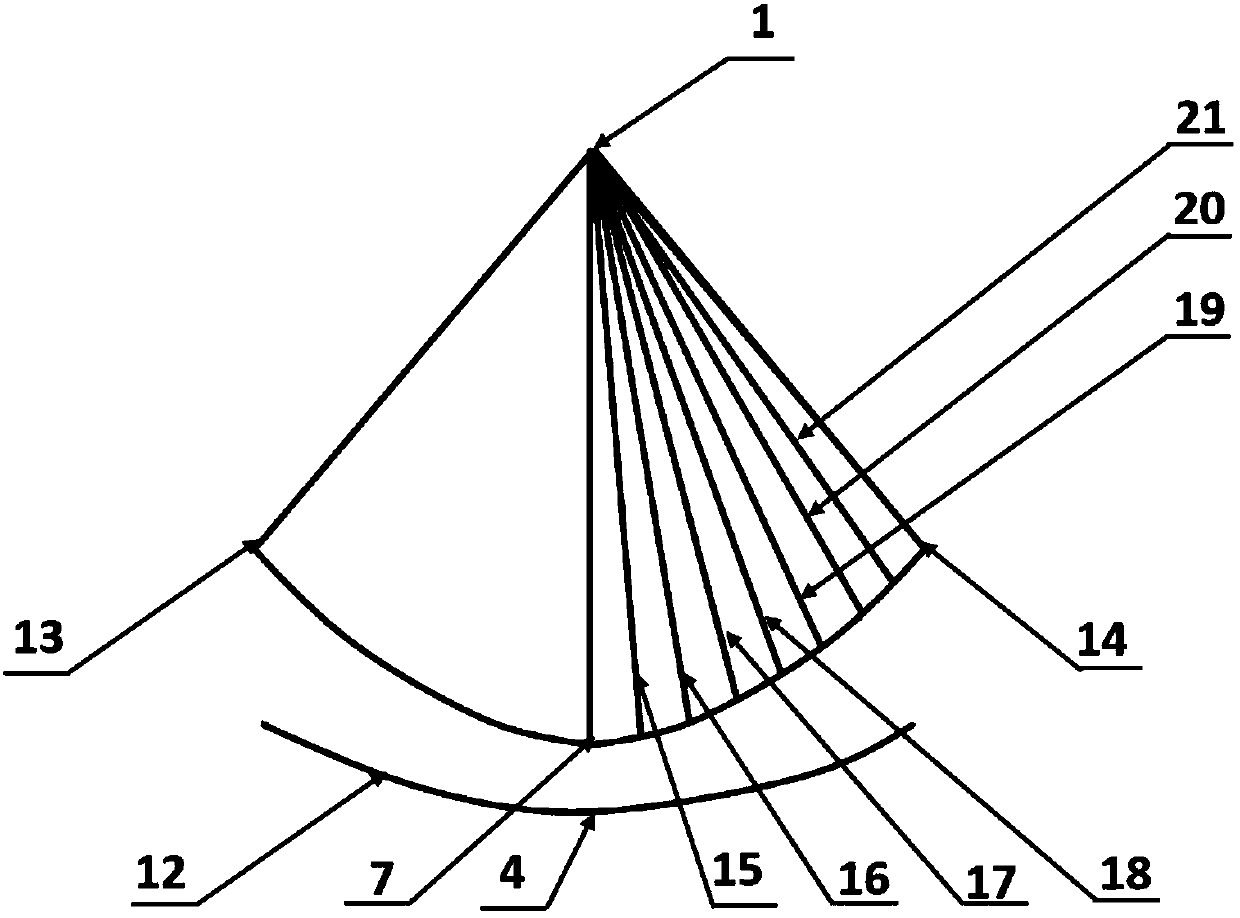

[0066] A method for designing a precompressed precursor of an axisymmetric aircraft with boundary layer displacement, comprising the following steps:

[0067] S1. Design pressure controllable flow field

[0068] The pressure controllable flow field designed in the present invention is a pressure controllable flow with external rotation axis symmetry, and the pressure controllable flow field is composed of a direct shock wave dependent flow field and a main compression flow field.

[0069] S1.1 Solve the conical flow field after the direct shock wave

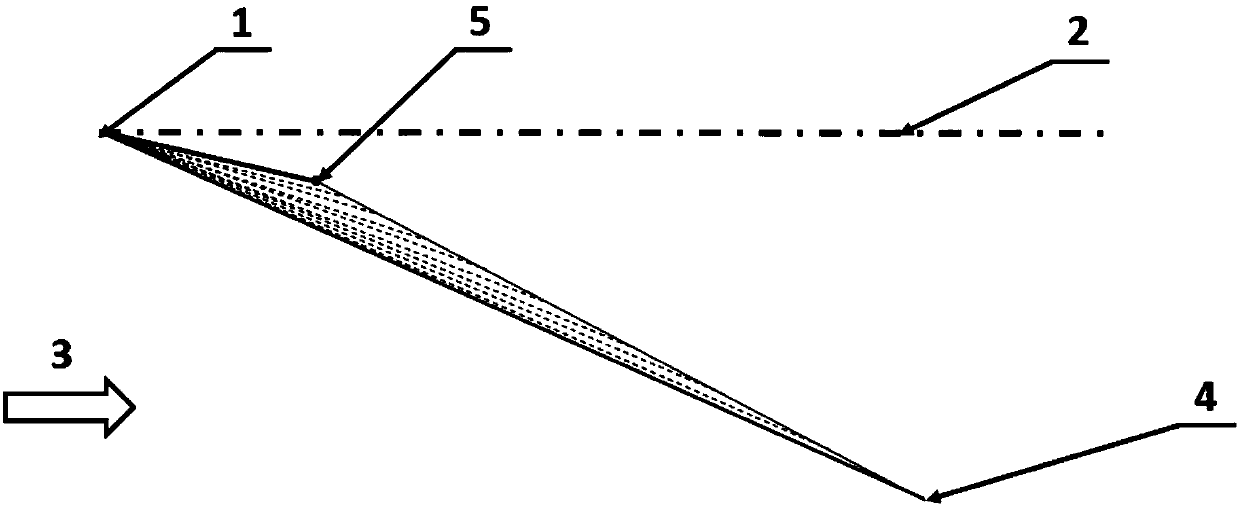

[0070] The leading edge point 1 of the aircraft, the central axis of the aircraft 2, the far-field incoming flow condition 3, and the lip center point 4 are known. The far-field incoming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com